Genetically engineered bacterium of bile salt hydrolase, bile salt hydrolase and application of bile salt hydrolase

A technology of bile salt hydrolyzing enzyme and genetically engineered bacteria, applied in the field of bile salt hydrolyzing enzyme and its application, bile salt hydrolyzing enzyme genetically engineered bacteria, can solve the problems of product quality impact, high energy, environmental pollution, etc., and achieve stable enzyme activity Good performance, strong catalytic ability, and good protein expression ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Construction of bile salt hydrolase engineering strain BSH7-BL21:

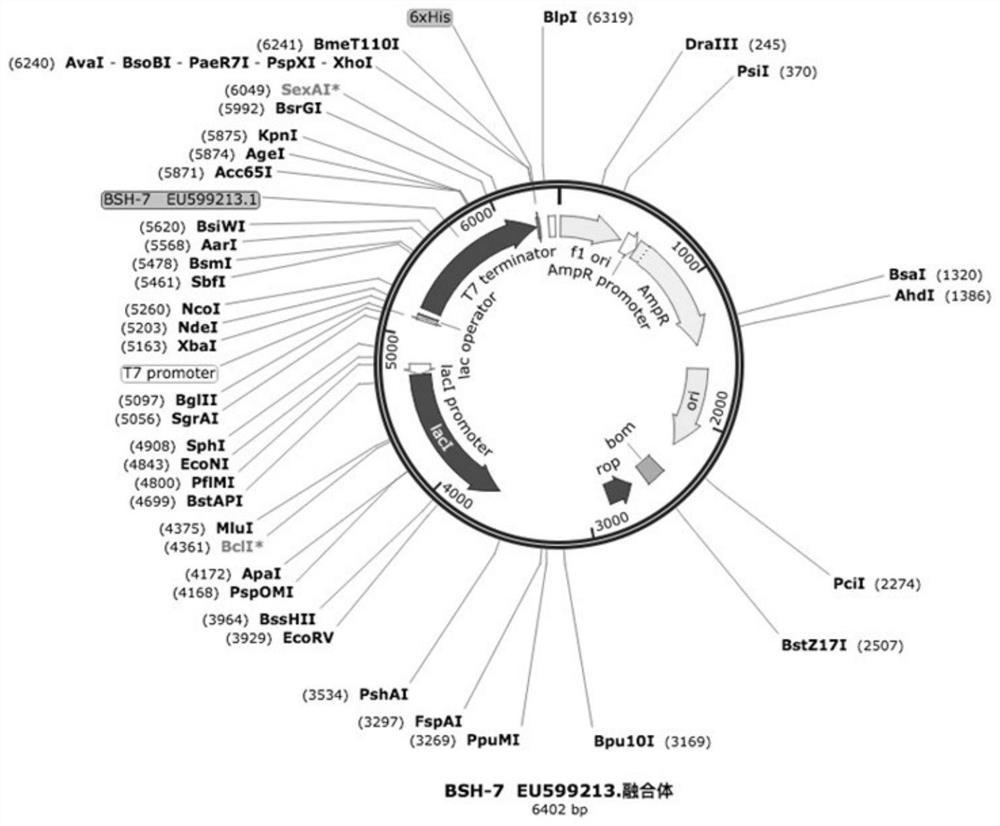

[0040] (1) The bile salt hydrolase gene was synthesized by conventional PCR. The nucleotide sequence of the bile salt hydrolase gene is shown in SEQ ID NO.1, including 338 amino acids and 1071 nucleotides in full length. Use the SanpGene software infusion to import into the vector plasmid pET-21a(+), and synthesize the recombinant plasmid bsh-pET-21a. The schematic diagram of the nucleotide distribution of the recombinant plasmid is as follows figure 1 shown;

[0041] (2) Transform the recombinant plasmid into the competent cells BL21 (DE3), then spread the transformed competent cells on LB plates containing 0.1 g / ml ampicillin, place them upside down in an incubator and cultivate them overnight for 14 hours to obtain the cloned strain BSH7-BL21 is a bile salt hydrolase engineering strain.

[0042] Preparation of bile salt hydrolyzing enzyme crude enzyme solution:

[0043] In a 250mL Erlenmeyer flask...

Embodiment 2

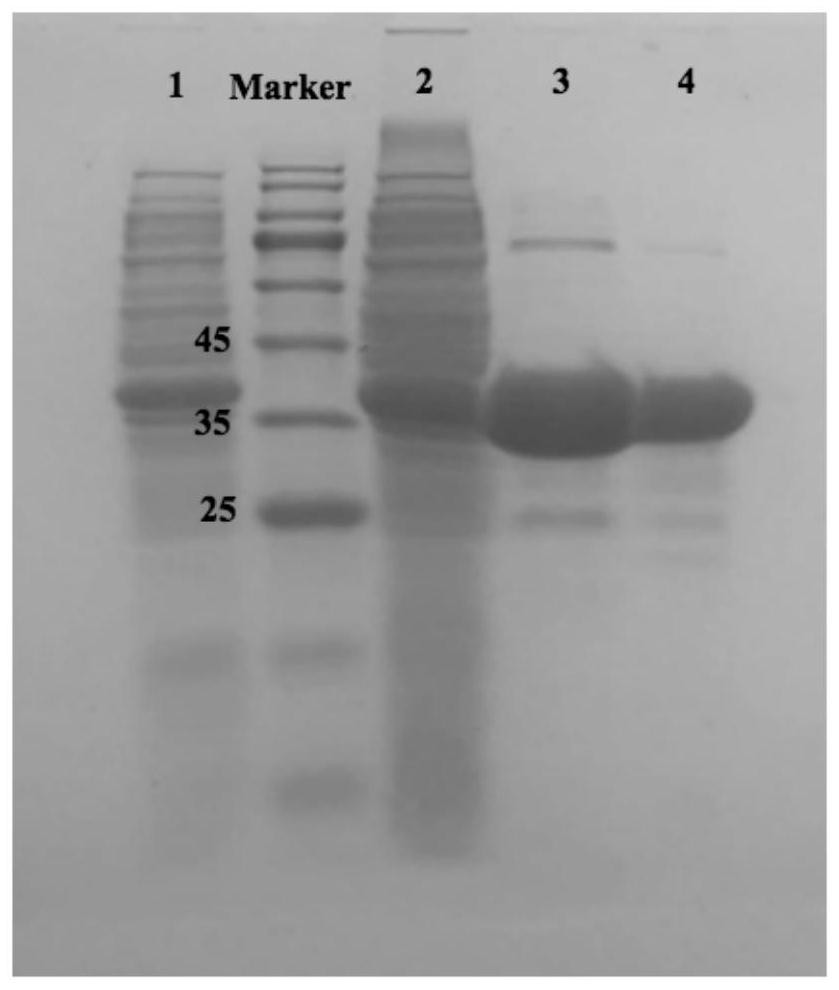

[0045] Extraction and purification of bile salt hydrolase:

[0046] (1) Take 4ml of the crude bile salt hydrolyzing enzyme solution prepared in Example 1, centrifuge (12000rpm, 1min), discard the supernatant, and resuspend with 2ml of 50mmoL Tri-HCl pH6.4 solution (resuspension ratio 2:1) As for the 5ml centrifuge tube, the cell disruptor is crushed in an ice bath (probe 6, 3min, run for 2s and stop for 4s);

[0047] (2) Take 40μL of the solution obtained in step (1), centrifuge (12000rpm, 1min), take out the supernatant, wash the lower layer with 50mmoL Tri-HCl pH6.4 solution twice, and finally resuspend with 40μL, in the upper and lower layers Add 10 μL of eluent to the liquid, and bathe in boiling water for 10 minutes.

[0048](3) The crude enzyme liquid of bile salt hydrolyzing enzyme obtained in step (2) is purified using an AKTA protein purifier, and the purification column used is a Ni-NTA packing column, and the washing buffer (Tris 50mM, NaCl 300mM, imidazole 30mM, ...

Embodiment 3

[0053] Bile salt hydrolase catalyzes the decomposition of amino acid surfactants:

[0054] Add 10.3 mg of N-lauroyl glycine to a centrifuge tube, add 1 mL of buffer solution (20 mM Tri-HCl, pH 6.0) and 100 μL of the crude bile salt hydrolyzing enzyme solution prepared in Example 1, and react at 37°C for 17 hours. Take 100 μL of the reaction solution, add 400 μL of buffer solution and 500 μL of methanol, mix well, filter, and detect the product by HPLC:

[0055] Inject 20 μL and set the flow rate to 1 mL / min. The mobile phase configuration is as follows: A phase is 0.1% trifluoroacetic acid-water solution, B phase is 0.1% trifluoroacetic acid-methanol solution; 0min, A phase 25%, B phase 75%; 3min, A phase 10%, B phase 90% %; 9min, A phase 10%, B phase 90%; 9.01min, A phase 25%, B phase 75%; 13min end. DVD detector detects at 210nm, column C185μm 4.6×150mm.

[0056] The test results show that the bile salt hydrolyzing enzyme prepared in the example of the present application...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com