Method for adjusting and controlling DM interaction of ferromagnetic multilayer film

A multi-layer film and ferromagnetic technology, applied in the field of high-density information storage and sensing, can solve the problems of difficult insulation, poor control uniformity, breakdown, etc., and achieve reduced surface roughness, good surface quality, and reduced oxidation layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

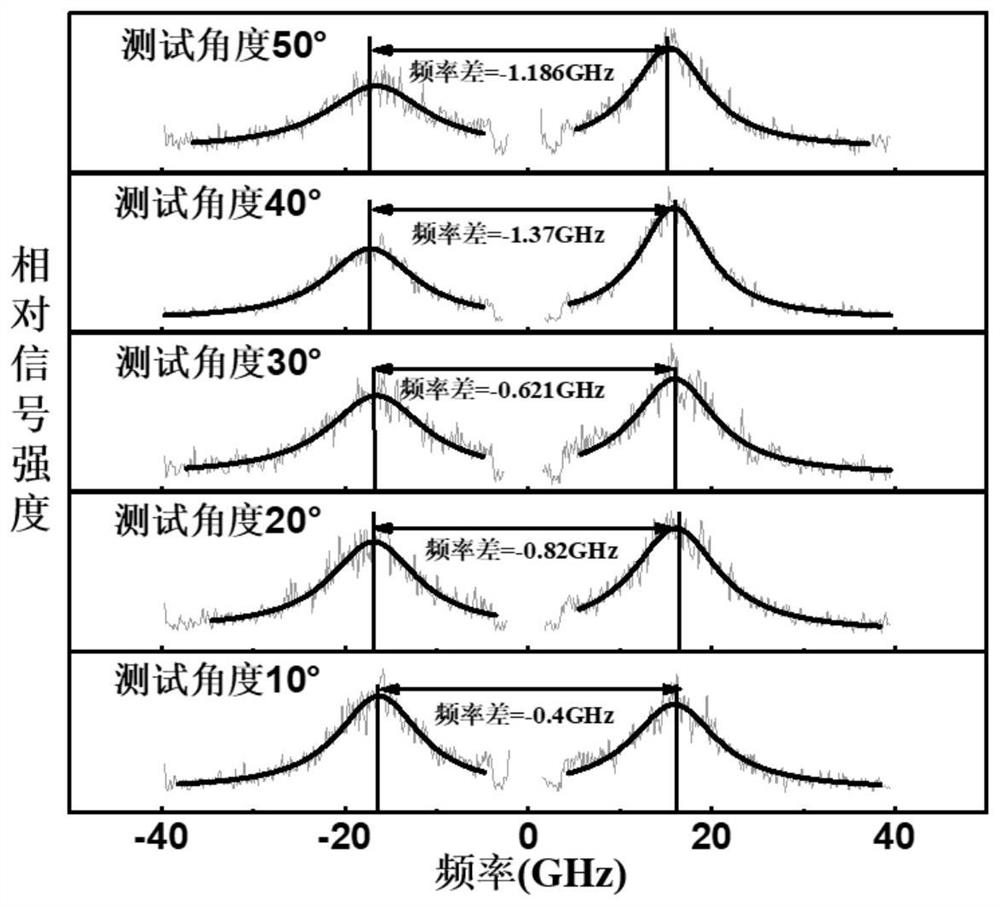

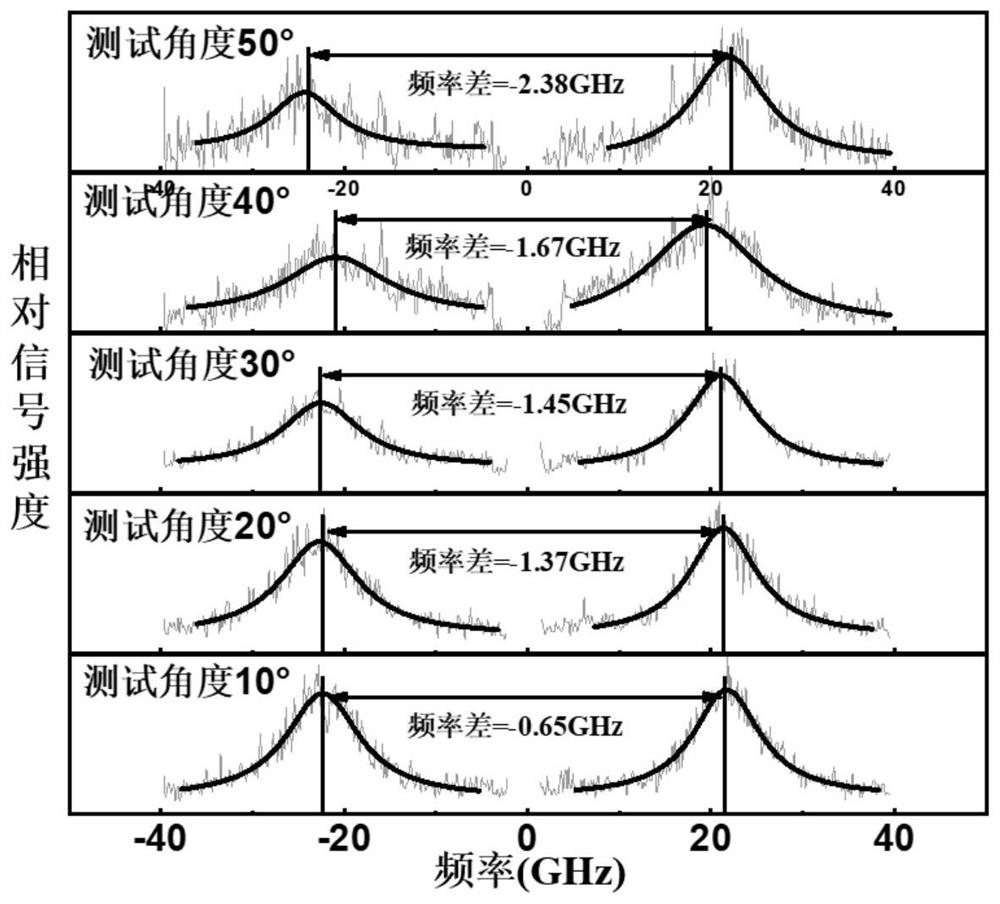

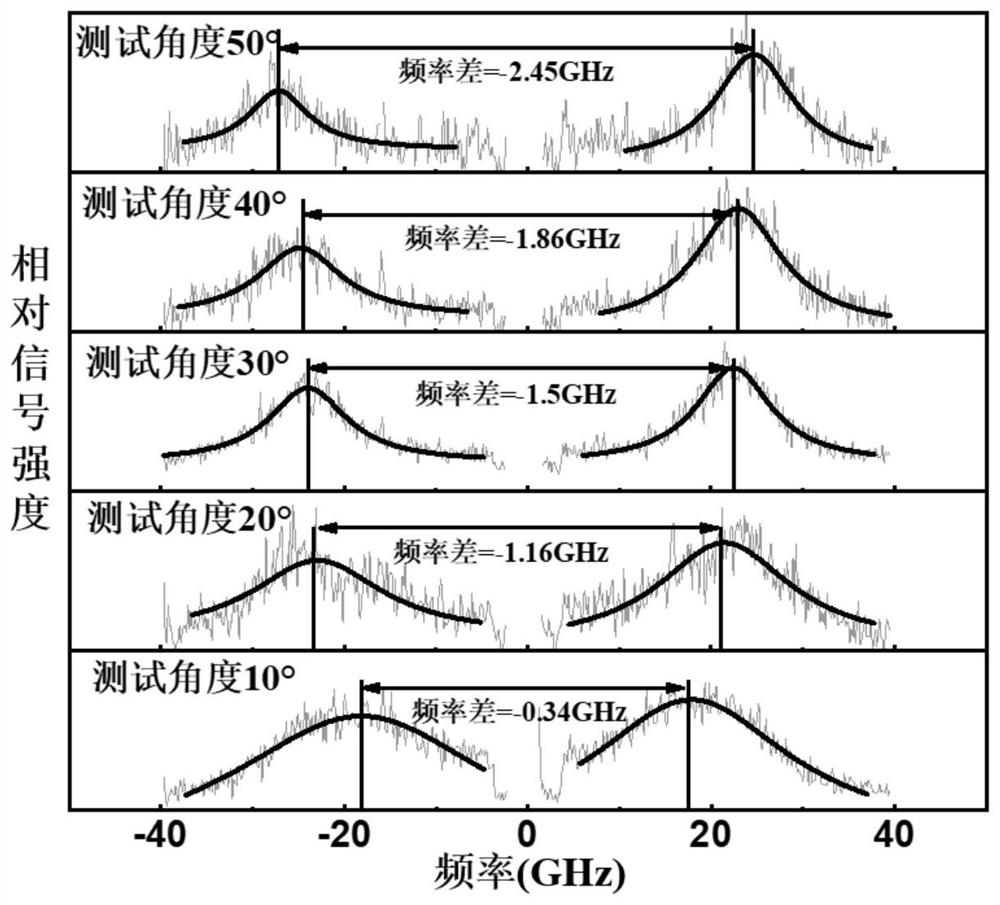

[0018] figure 1 The sample preparation conditions are as follows: firstly, the Si substrate with a thickness of 0.5 mm is cut into a suitable size, and the surface acidification treatment and heat treatment are carried out on it. Hydrofluoric acid is used for the surface acidification treatment, the pH value of the acidification treatment is 6, and the acidification time is 3 minutes. Afterwards, the substrates were ultrasonically cleaned with alcohol and acetone solutions respectively, the cleaning sequence was first the acetone solution and then the alcohol solution, and were cleaned twice, each time for 10 minutes. Then, utilize the magnetron sputtering method to sequentially deposit Pt atoms (with a thickness of ), Co atoms (thickness is ) and Ta atoms (thickness is ), the sputtering powers were 15W, 18W and 30W, respectively, to prepare Si substrates multilayer film. The background vacuum of the sputtering chamber is 1×10 -5 Pa, the flow rate of argon gas during...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com