Gallium nitride-based green laser and preparation method thereof

A gallium nitride-based laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve problems such as weak luminous intensity, achieve the effects of reducing optical absorption loss, improving quantum efficiency, and increasing green luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

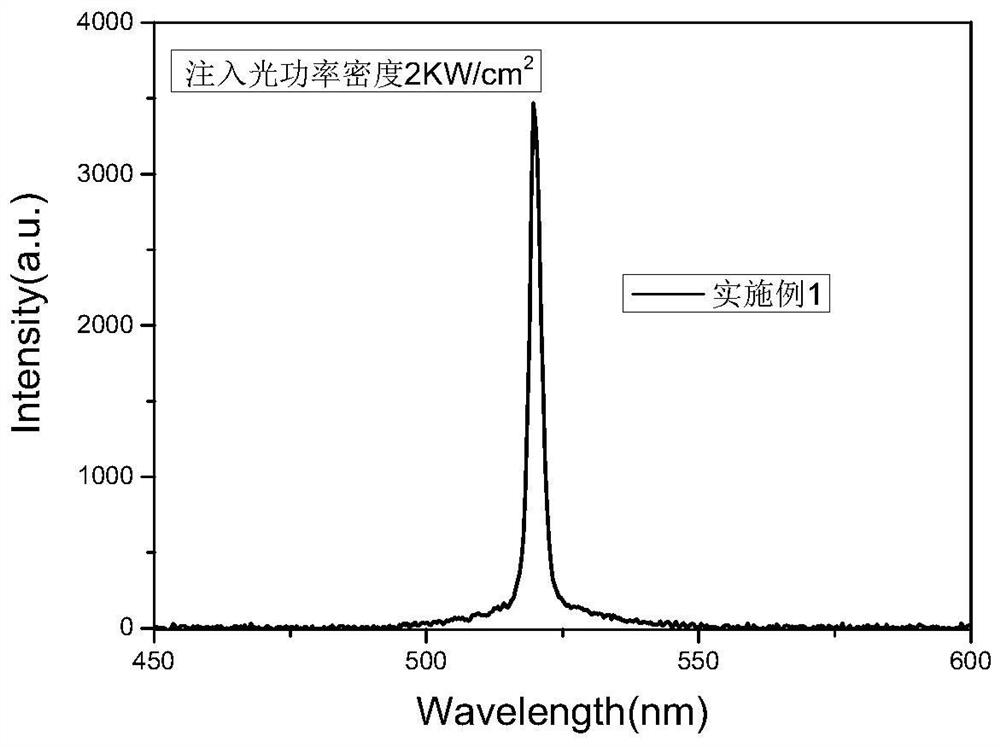

Embodiment 1

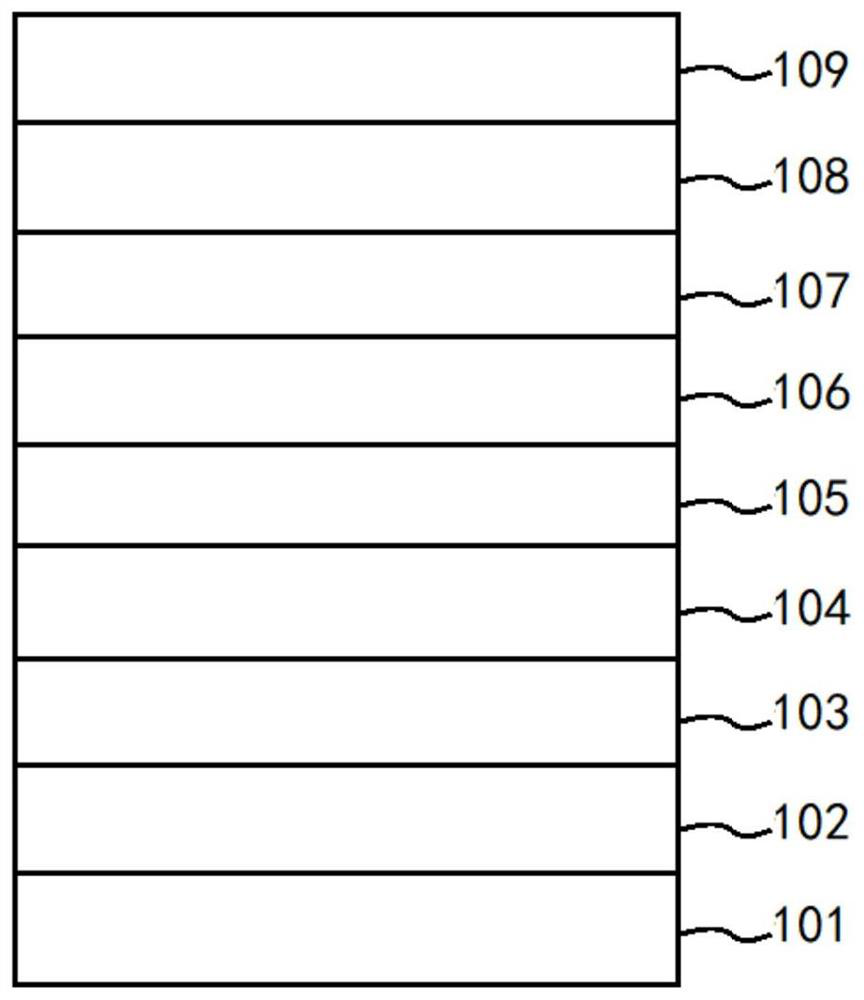

[0073] This embodiment provides a gallium nitride-based green laser, such as figure 1 As shown, it includes gallium nitride single crystal substrate 101, n-GaN layer 102, n-AlGaN / GaN superlattice confinement layer 103, lower waveguide layer 104, active region 105, p Type electron blocking layer 106, upper waveguide layer 107, p-AlGaN / GaN superlattice confinement layer 108, p-GaN contact layer 109.

[0074] The GaN-based green laser is prepared through the following steps:

[0075] S1. First, in the metal organic compound vapor phase epitaxy reaction chamber, in a hydrogen atmosphere, the temperature is raised to 500-700°C, and then ammonia gas is introduced to form a mixed atmosphere of hydrogen and ammonia, and then the temperature is raised to 900-1100°C. The single crystal substrate is subjected to surface activation treatment for 3-15 minutes.

[0076] S2. In a hydrogen atmosphere, at a temperature of 950-1200°C, feed trimethylgallium as the source of Group III, ammonia ...

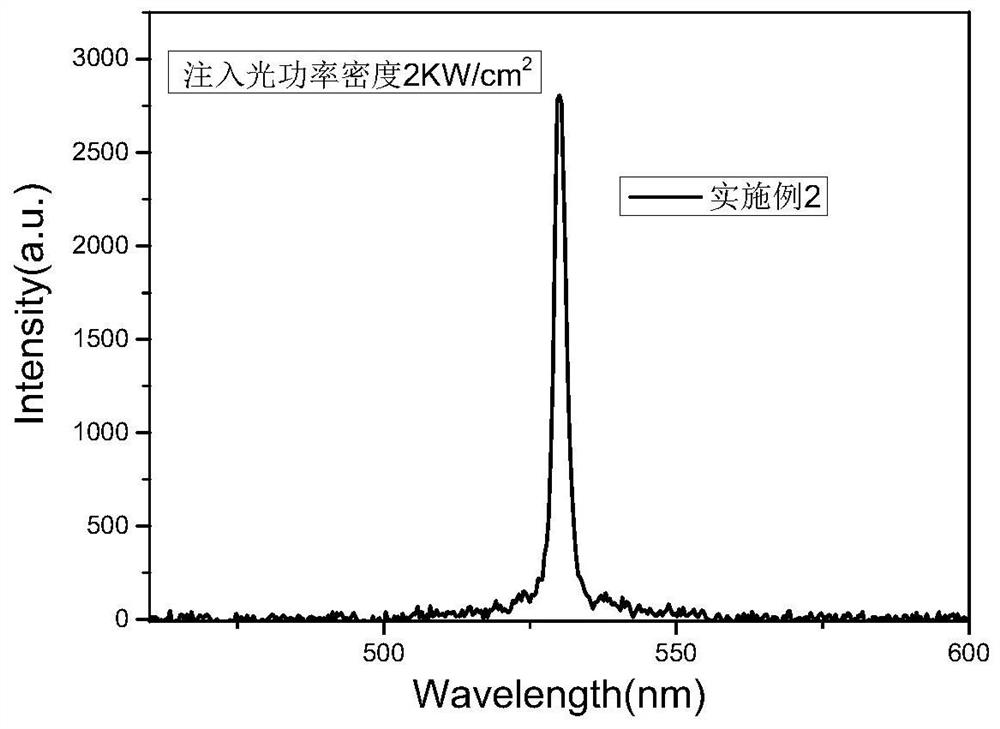

Embodiment 2

[0106] This embodiment provides a gallium nitride-based green laser, such as figure 1 As shown, it includes gallium nitride single crystal substrate 101, n-GaN layer 102, n-AlGaN / GaN superlattice confinement layer 103, lower waveguide layer 104, active region 105, p Type electron blocking layer 106, upper waveguide layer 107, p-AlGaN / GaN superlattice confinement layer 108, p-GaN contact layer 109.

[0107] The GaN-based green laser is prepared through the following steps:

[0108] S1. First, in the metal organic compound vapor phase epitaxy reaction chamber, in a hydrogen atmosphere, the temperature is raised to 500-700°C, and then ammonia gas is introduced to form a mixed atmosphere of hydrogen and ammonia, and then the temperature is raised to 900-1100°C. The single crystal substrate is subjected to surface activation treatment for 3-15 minutes.

[0109] S2. In a hydrogen atmosphere, at a temperature of 950-1200°C, feed trimethylgallium as the source of Group III, ammonia ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com