Antibacterial titanium and titanium alloy medical implant and preparation method thereof

A titanium alloy and plant technology, which is applied in the field of antibacterial titanium and titanium alloy medical implants and its preparation, can solve the problems of increased drug resistance of patients, reduced therapeutic effect of antibiotic-resistant patients, and complex biological safety assessment, etc. Effects of potential risk, excellent corrosion resistance and wear resistance, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

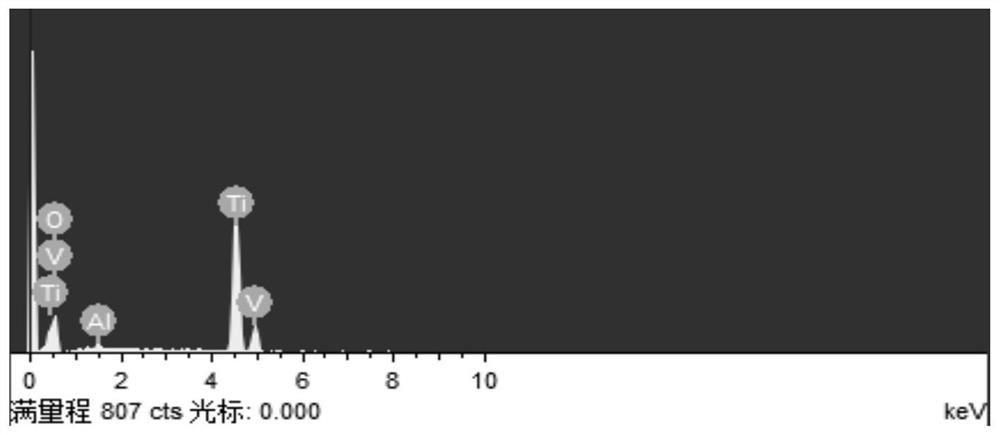

Image

Examples

Embodiment 1

[0043] S1. Pretreatment: Ultrasonic cleaning the sample of the plant body in the titanium alloy medical device to be treated with mixed acid solution, acetone, ethanol, and deionized water for 20 minutes each, and then drying to obtain a clean plant body in the titanium alloy medical device. Wherein, the mixed acid solution is composed of hydrofluoric acid, nitric acid and deionized water, and in the mixed acid solution, the mass fraction of hydrofluoric acid is 5%, and the mass fraction of nitric acid is 50%.

[0044] S2. Alkali-heat soaking treatment: immerse the clean titanium alloy medical device internal plant body in 1mol / L NaOH aqueous solution, heat to 120°C for 1 hour, take out the titanium alloy medical device internal plant body after cooling, and clean it with deionized water. Dry in an oven at 40°C to obtain alkali-treated endoplants.

[0045] S3. The first roasting treatment: the alkali-treated inner plants were heated to 500° C. in a tube furnace and kept for 1 ...

Embodiment 2

[0054] S1. Pretreatment: Ultrasonic cleaning the sample of the plant body in the titanium alloy medical device to be treated with mixed acid solution, acetone, ethanol, and deionized water for 10 minutes each, and then drying to obtain a clean plant body in the titanium alloy medical device. Wherein, the mixed acid solution is composed of hydrofluoric acid, nitric acid and deionized water, and in the mixed acid solution, the mass fraction of hydrofluoric acid is 5%, and the mass fraction of nitric acid is 50%.

[0055] S2. Alkali-heat soaking treatment: immerse the clean titanium alloy medical device internal plant body in 5mol / L NaOH aqueous solution, heat to 240°C for 5 hours, take out the titanium alloy medical device internal plant body after cooling, and clean it with deionized water. Dry in an oven at 40°C to obtain alkali-treated endoplants.

[0056] S3. The first roasting treatment: the alkali-treated inner plants were heated in a tube furnace to 300° C., then kept for...

Embodiment 3

[0063] S1. Pretreatment: Ultrasonic cleaning the sample of the plant body in the titanium alloy medical device to be treated with mixed acid solution, acetone, ethanol, and deionized water for 30 minutes each, and then drying to obtain a clean plant body in the titanium alloy medical device. Wherein, the mixed acid solution is composed of hydrofluoric acid, nitric acid and deionized water, and in the mixed acid solution, the mass fraction of hydrofluoric acid is 5%, and the mass fraction of nitric acid is 50%.

[0064] S2. Alkali-heat soaking treatment: immerse the clean titanium alloy medical device internal plant body in 10mol / L NaOH aqueous solution, heat it to 100°C for 1 hour, take out the titanium alloy medical device internal plant body after cooling, and clean it with deionized water. Dry in an oven at 40°C to obtain alkali-treated endoplants.

[0065] S3. The first roasting treatment: the alkali-treated inner plants were heated to 600° C. in a tube furnace for 2 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com