Washable high-temperature-resistant conductive photocuring material for 3D printing and printing process thereof

A light-curing material and 3D printing technology, applied in the field of 3D printing, can solve the problems of poor dimensional stability of conductive wires, not environmental protection, too many processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

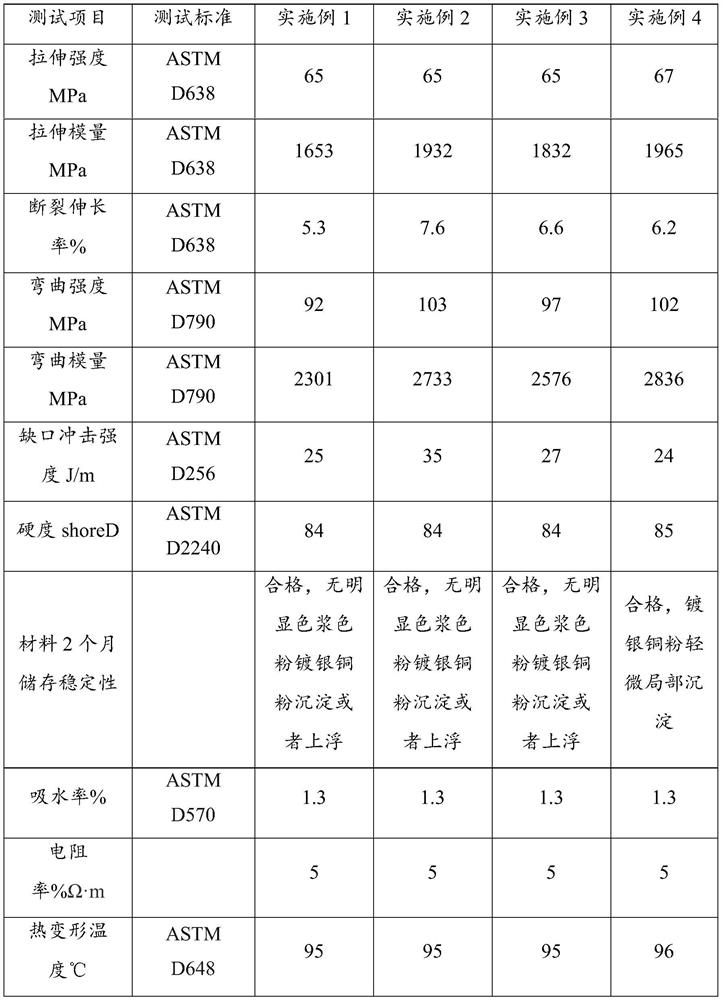

Embodiment 1

[0029] A water-washable, high-temperature, and conductive 3D printing light-curing material, the mass ratio of which is as follows:

[0030] Water-based epoxy acrylate 10g, water-based polyester acrylate 10g, monofunctional radical acrylate monomer 10g, high-strength aliphatic urethane acrylate 10g, pigment 1g, 2,4,6-trimethylbenzoyl-di 1g of phenylphosphine oxide, 1g of silver-plated copper powder, 1g of fumed nano-silica, 1g of dispersant, and 1g of anti-sedimentation aid.

[0031] The method for the light-curing material includes the following steps: mixing each raw material component according to the proportion by weight, and then stirring at 25 degrees for 30 minutes to obtain a uniform liquid.

[0032] The wetting and dispersing agent adopts BYK D-193 wetting and dispersing agent

[0033] The pigment is black paste.

[0034] The anti-sedimentation aid is a mixture of polyamide wax and oxidized polyethylene wax, such as Japan Disparon anti-sedimentation aid NS-5501.

[0...

Embodiment 2

[0040] A water-washable, high-temperature, and conductive 3D printing light-curing material, the mass ratio of which is as follows:

[0041] 30g water-based epoxy acrylic acid, 30g water-based polyester acrylate, 30g monofunctional radical acrylate monomer, 30g high-strength aliphatic urethane acrylate, 5g pigment, 2,4,6-trimethylbenzoyl-diphenyl Base phosphine oxide 10g, silver-plated copper powder 10g, fumed nano-silica 10g, dispersant 10g, anti-sedimentation additive 10g.

[0042] The method for the light-curing material includes the following steps: mixing each raw material component according to the proportion by weight, and then stirring at 50 degrees for 45 minutes to obtain a uniform liquid.

[0043] The wetting and dispersing agent adopts BYK D-193 wetting and dispersing agent

[0044] The pigment is black paste.

[0045] The anti-sedimentation aid is a mixture of polyamide wax and oxidized polyethylene wax, such as Japan Disparon anti-sedimentation aid NS-5501.

...

Embodiment 3

[0051] A water-washable, high-temperature, and conductive 3D printing light-curing material, the mass ratio of which is as follows:

[0052] 20g water-based epoxy acrylic acid, 20g water-based polyester acrylate, 20g monofunctional radical acrylate monomer, 20g high-strength aliphatic urethane acrylate, 3g pigment, 2,4,6-trimethylbenzoyl-diphenyl Phosphine oxide 5g, silver-plated copper powder 5g, fumed nano-silica 5g, dispersant 5g, anti-sedimentation additive 5g.

[0053] The method for the light-curing material comprises the following steps: mixing each raw material component according to the proportion by weight, and then stirring at 25 degrees for 35 minutes to obtain a uniform liquid.

[0054] The wetting and dispersing agent adopts BYK D-193 wetting and dispersing agent

[0055] The pigment is black paste.

[0056] The anti-sedimentation aid is a mixture of polyamide wax and oxidized polyethylene wax, such as Japan Disparon anti-sedimentation aid NS-5501.

[0057] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com