A kind of graphene oxide high barrier composite film and preparation method

A graphene composite and composite film technology, applied in the fields of electronic packaging and food, can solve problems such as damage and decrease in barrier properties of films containing oxygen absorbers, and achieve the effects of avoiding agglomeration, increasing oxygen barrier properties, and increasing interlayer spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

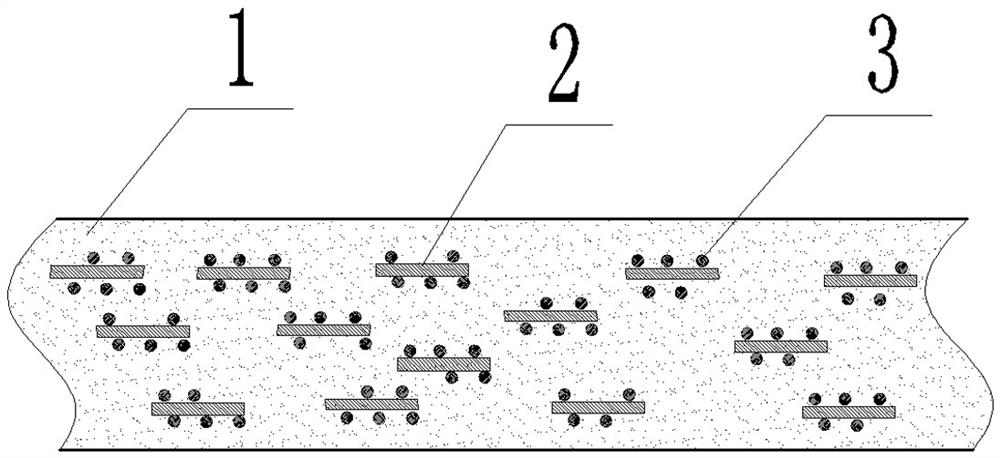

Image

Examples

Embodiment 1

[0029] A graphene oxide high-barrier composite film and a preparation method thereof. The preparation raw materials are, in parts by mass, 92 parts of PET, 8 parts of oxygen-absorbing graphene oxide composite particles, and 0.08 parts of cobalt neodecanoate. The raw materials of the oxygen-absorbing graphene oxide composite particles are 10 parts by mass of 1,4-butene diol and 90 parts of graphene oxide.

[0030] The preparation method is:

[0031] (1) Dissolve 0.5g of graphene oxide in 500ml of ethanol, and ultrasonicate for 30min at 25°C until a uniform brown solution is obtained; at the same time, dissolve 0.5g of 1,4-butenediol (oxygen absorber) in 50ml of ethanol, Sonicate at room temperature for 15 minutes until 1,4-butenediol is completely dissolved. Mix the two solutions in a certain ratio (the ratio of mass parts is 1,4-butene diol: graphene oxide = 1:9), mechanically stir at 40°C for more than 4 hours, ultrasonicate the reaction solution for 30 minutes, and then ref...

Embodiment 2

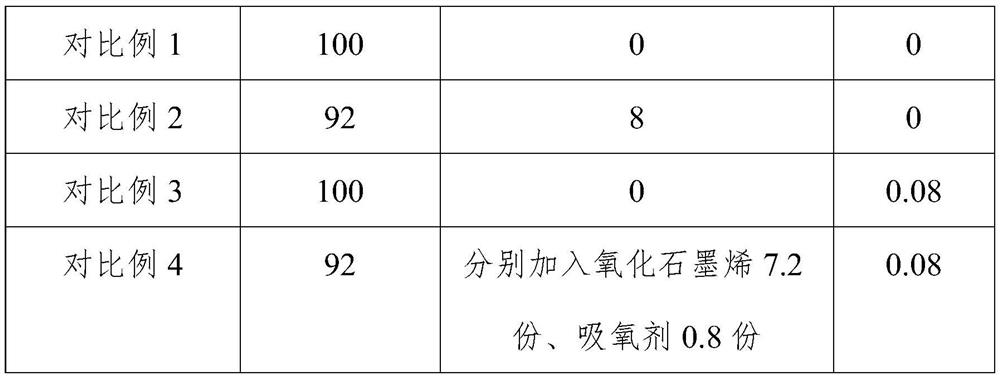

[0034] The proportioning ratios of Example 2, Example 3, and Comparative Examples 1-4 are shown in Table 1, and the preparation method refers to Example 1.

[0035] Table 1 Formula table of graphene oxide high barrier PET composite film

[0036]

[0037]

Embodiment 4-5

[0038] Embodiment 4-5, comparative example 5-6, the formula of reference example 2, 95 parts of PET resins, 5 parts of oxygen-absorbing type graphene oxide composite particles, 0.05 part of catalysts, wherein the oxygen-absorbing type graphene oxide composite particles absorb The ratio of oxygen agent and graphene oxide is shown in Table 2.

[0039] Table 2 Formula table of oxygen-absorbing graphene oxide composite particles

[0040] experiment oxygen absorber Graphene oxide Example 2 10 90 Example 4 6 94 Example 5 20 80 Comparative example 5 50 50 Comparative example 6 70 30

[0041]For Comparative Example 7 and Examples 7-9, PEN resin was selected, and the preparation method refers to Example 1, and the specific formula is shown in Table 3.

[0042] Table 3 Graphene oxide high barrier PEN composite film formula table

[0043]

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com