A narrow-band b-zone ultraviolet long-lasting luminescent material and its preparation method and application

A luminescent material and narrow-band technology, which is applied in the field of narrow-band B-zone ultraviolet long-lasting luminescent material and its preparation, can solve the problems of insufficient intensity and short afterglow time, and achieve the effects of good crystallization performance, low equipment requirements, and no by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In the second aspect of the present invention, the present invention proposes a preparation method of a narrow-band B-region ultraviolet long-lasting luminescent material, which includes: mixing the material and a flux, first performing low-temperature pre-calcination, and then performing high-temperature sintering to obtain a narrow-band B-region ultraviolet long-lasting luminescent material. Afterglow luminescent material; said material includes Y-containing compound, Gd-containing compound, Ga-containing compound and Bi-containing compound.

[0038] Low-temperature pre-calcination can effectively remove volatile components in raw materials, such as surface-adsorbed moisture or CO produced by carbonate decomposition 2 , so as to obtain ceramic powder with high sintering activity and uniform and stable composition. Therefore, the combination of low temperature sintering and high temperature sintering can reduce the shrinkage of the material and effectively improve the ...

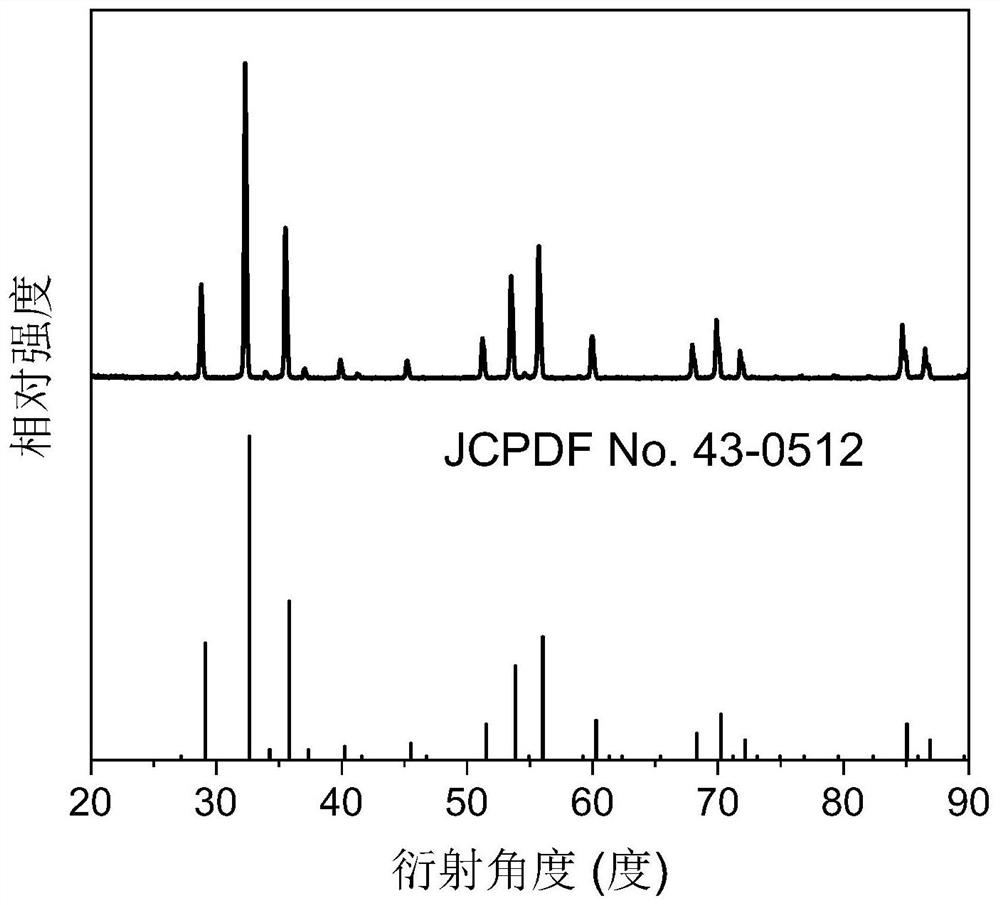

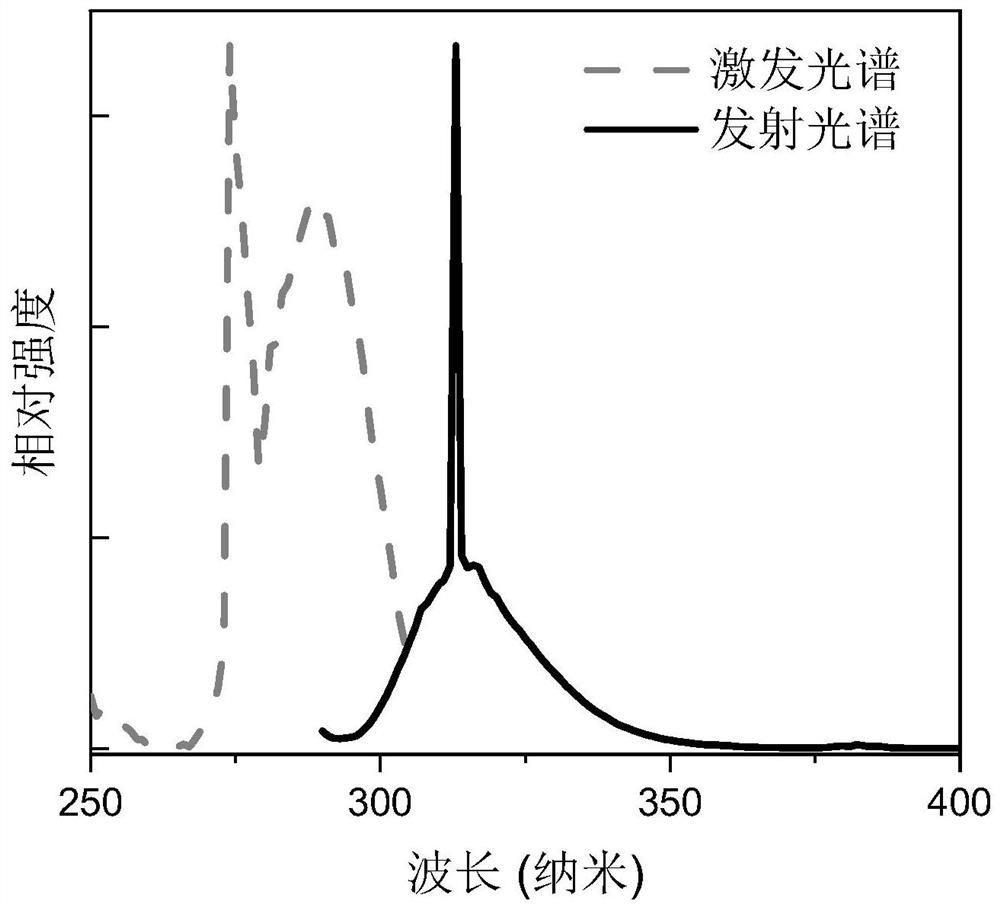

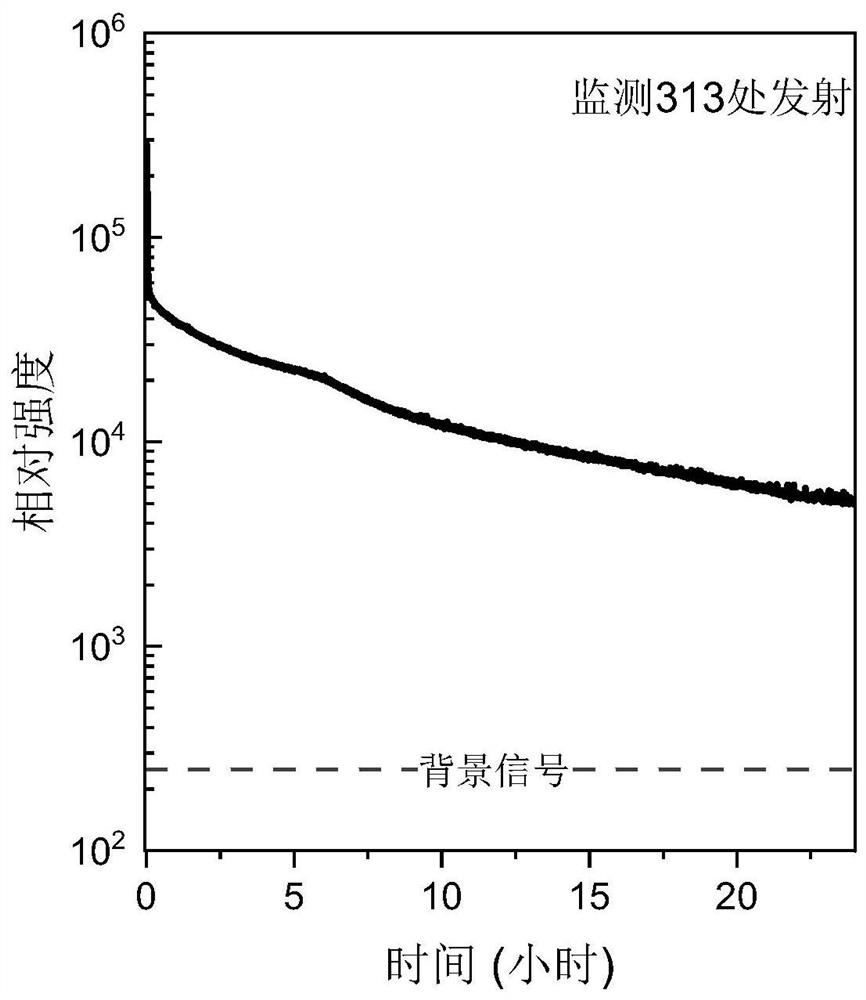

Embodiment 1

[0058] According to the following ingredients: narrow-band B-zone ultraviolet long-lasting luminescent material Y 2.497 Gd 0.5 Ga 5 o 12 :0.3% Bi 3+ , with Y 2.495 Gd 0.5 Ga 5 o 12 is the host, and the dopant ion is Bi 3+ Ions, where Bi 3+ The doping amount is 0.3mol%. Accurately weigh yttrium oxide (Y 2 o 3 ) 0.7048g, gadolinium oxide (Gd 2 o 3 )0.2266g, gallium oxide (Ga 2 o 3 ) 1.1715g, bismuth oxide (Bi 2 o 3 ) 0.0017g. Grind the above raw materials in an agate mortar for about 1 hour, mix the raw materials thoroughly, then transfer them to a corundum crucible, and pre-fire them at 900°C for 2 hours. After the calcined powder is reground, use a powder tablet press to press about 1 g of the powder into a disc with a diameter of about 15 mm and a thickness of about 1 mm. Finally, the formed wafer was sintered at 1500°C for 4 hours to obtain the solar-excitable Y 2.497 Gd 0.5 Ga 5 o 12 :0.3% Bi 3+ Narrow-band B-region ultraviolet long afterglow lumines...

Embodiment 2

[0071] According to the following ingredients: narrow-band B-zone ultraviolet long-lasting luminescent material Y 2.895 Gd 0.1 Ga 5 o 12 :0.5% Bi 3+ , with Y 2.895 Gd 0.1 Ga 5 o 12 is the host, and the dopant ion is Bi 3+ Ions, where Bi 3+ The doping amount is 0.5mol%. Accurately weigh yttrium oxide (Y 2 o 3 ) 0.8171g, gadolinium oxide (Gd 2 o 3 ) 0.0453g, gallium oxide (Ga 2 o 3 ) 1.1715g, bismuth oxide (Bi 2 o 3 ) 0.0029g. Grind the above raw materials in an agate mortar for about 1 hour, mix the raw materials thoroughly, then transfer them to a corundum crucible, and pre-fire at 850°C for 3 hours. After the calcined powder is reground, use a powder tablet press to press about 1 g of the powder into a disc with a diameter of about 15 mm and a thickness of about 1 mm. Finally, the shaped wafer was sintered at 1550°C for 6 hours to obtain the solar-excitable Y 2.895 Gd 0.1 Ga 5 o 12 :0.5% Bi 3+ Narrow-band B-region ultraviolet long afterglow luminescent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com