Low-vanadium nitrogenous hot work die steel and manufacturing method thereof

A technology for hot-working die steel and steel ingots, which is applied in the field of materials and metallurgy, and can solve problems such as large segregation tendency, restrictions on industrialization promotion, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]The composition of low vanadium nitrogen hot work die steel contains C 0.36%, Si 0.38%, Mn 0.23%, Cr 5.02%, Mo 1.55%, V 0.52%, N 0.041%, Ce 0.0025%, Mg 0.003% by mass percentage , the balance is Fe; the hardness is 51HRC, the tensile strength is 1650MPa, the yield strength is 1350MPa, and the impact absorption energy is 24J;

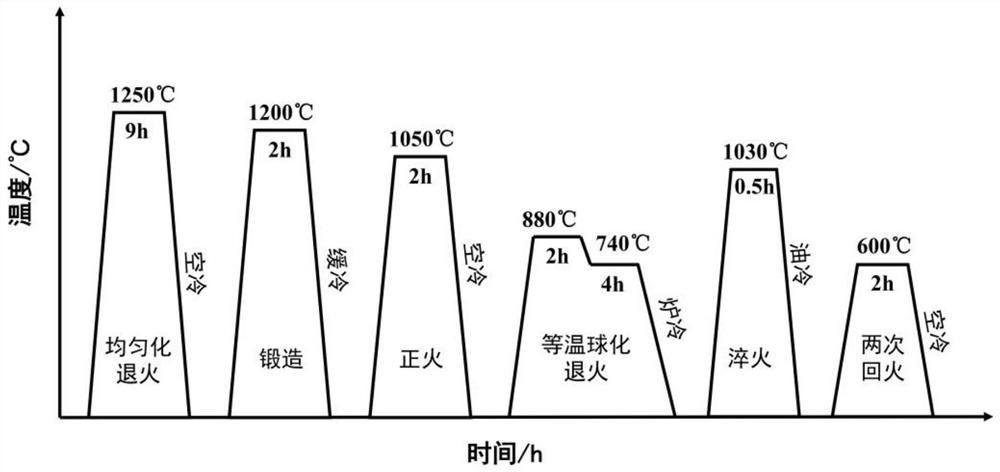

[0037] The preparation method is:

[0038] Industrial pure iron, molybdenum rods, metal chromium, graphite, industrial silicon, electrolytic manganese, metal vanadium and rare earth magnesium alloy are used as raw materials; industrial pure iron, molybdenum rods, metal chromium and the first part of graphite are placed in the alloy silo, pumped Vacuum and start to heat up. Before the material in the silo starts to melt, keep the vacuum degree in the silo ≤ 3Pa; when the material in the silo starts to melt, control the vacuum degree ≤ 10Pa, stop vacuuming and introduce argon to the pressure in the silo 40000Pa; after all the materials in the silo a...

Embodiment 2

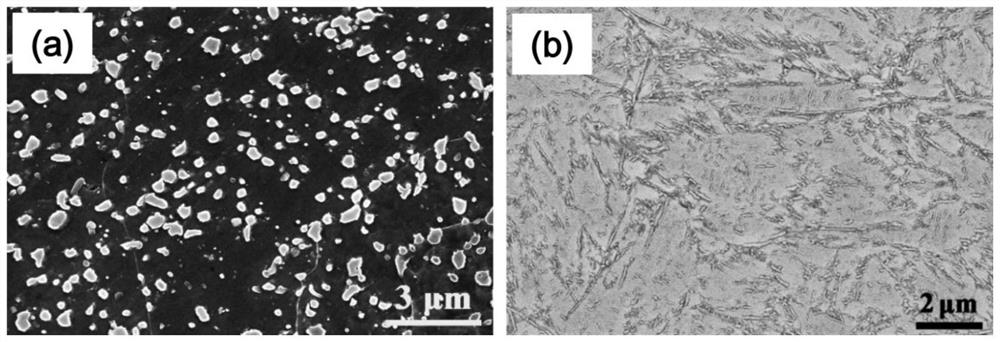

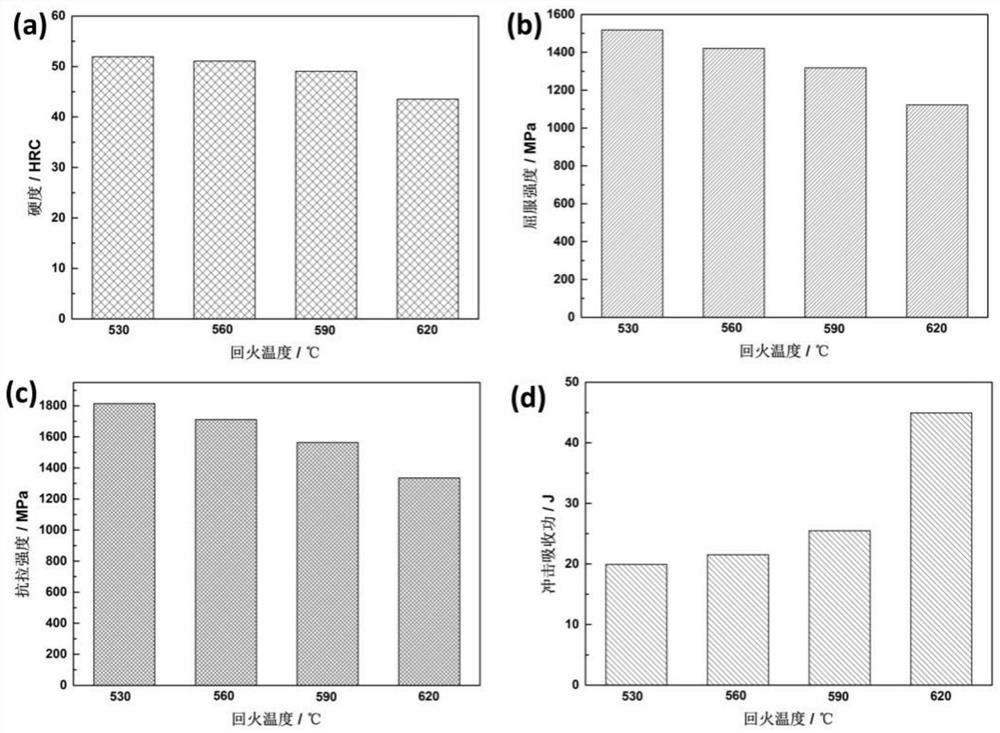

[0047] The composition of low vanadium nitrogen hot work die steel contains C 0.32%, Si 0.41%, Mn 0.31%, Cr 4.95%, Mo 1.48%, V 0.5%, N 0.05%, Ce 0.007%, Mg 0.004% by mass percentage , the balance is Fe; the hardness is 53HRC, the tensile strength is 1800MPa, the yield strength is 1550MPa, the impact absorption energy is 20J, and the performance is as follows image 3 shown;

[0048] The preparation method is:

[0049] Industrial pure iron, molybdenum rods, metal chromium, graphite, industrial silicon, electrolytic manganese, metal vanadium and rare earth magnesium alloy are used as raw materials; industrial pure iron, molybdenum rods, metal chromium, graphite, industrial silicon, electrolytic manganese and metal vanadium are placed In the ladle, the melting, refining, degassing and temperature control processes are respectively completed by using the EAF-LF-VD process; after the VD process is completed, the smelted ladle returns to the LF station, and when the melt temperatur...

Embodiment 3

[0057] The composition of low vanadium nitrogen hot work die steel contains C 0.35%, Si 0.48%, Mn 0.42%, Cr 5.24%, Mo 1.36%, V 0.46%, N 0.04%, Ce 0.013%, Mg 0.005% by mass percentage , the balance is Fe; the hardness is 50HRC, the tensile strength is 1690MPa, the yield strength is 1400MPa, the impact absorption energy is 22J, and the performance is as follows image 3 shown;

[0058] Preparation method is with embodiment 2, and difference is:

[0059] (1) When the melt temperature in the ladle is 1550°C, nitrogen gas is introduced for gas phase nitriding;

[0060] (2) The soft blowing time is 20 minutes;

[0061] (3) The steel ingot is used as the consumable electrode, and the electroslag remelting method is used to melt the consumable electrode to form droplets passing through the slag pool, and to refine and purify the slag-gold reaction to obtain a remelted ingot; Heat the ingot to 1210°C and keep it warm for 11 hours for homogenization to obtain a homogeneous ingot;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com