Preparation process of self-coated isolated plastic particles

A plastic particle and preparation technology, applied in the field of plastic processing, can solve the problems of denaturation, lowering the quality of plastic products, excessive loss of functional components of plastic particles, etc., and achieve the effect of improving uniformity, improving binding force and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

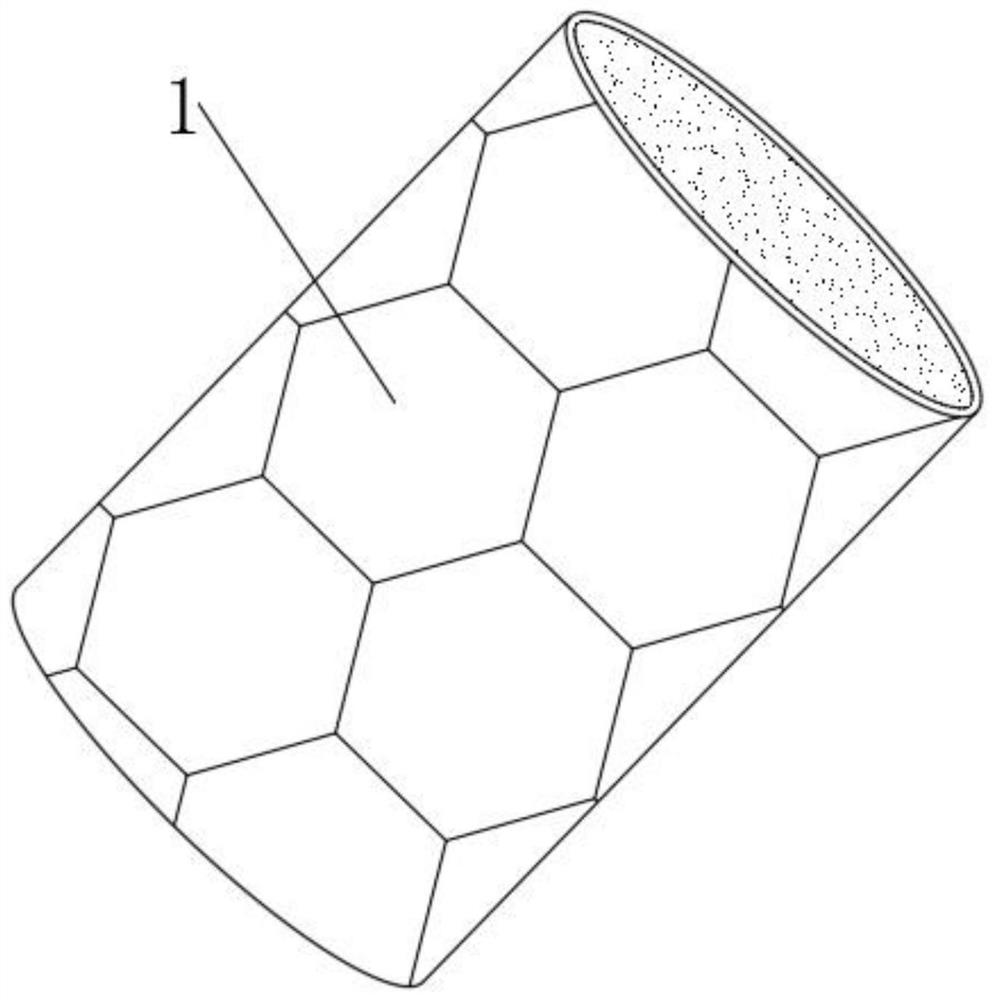

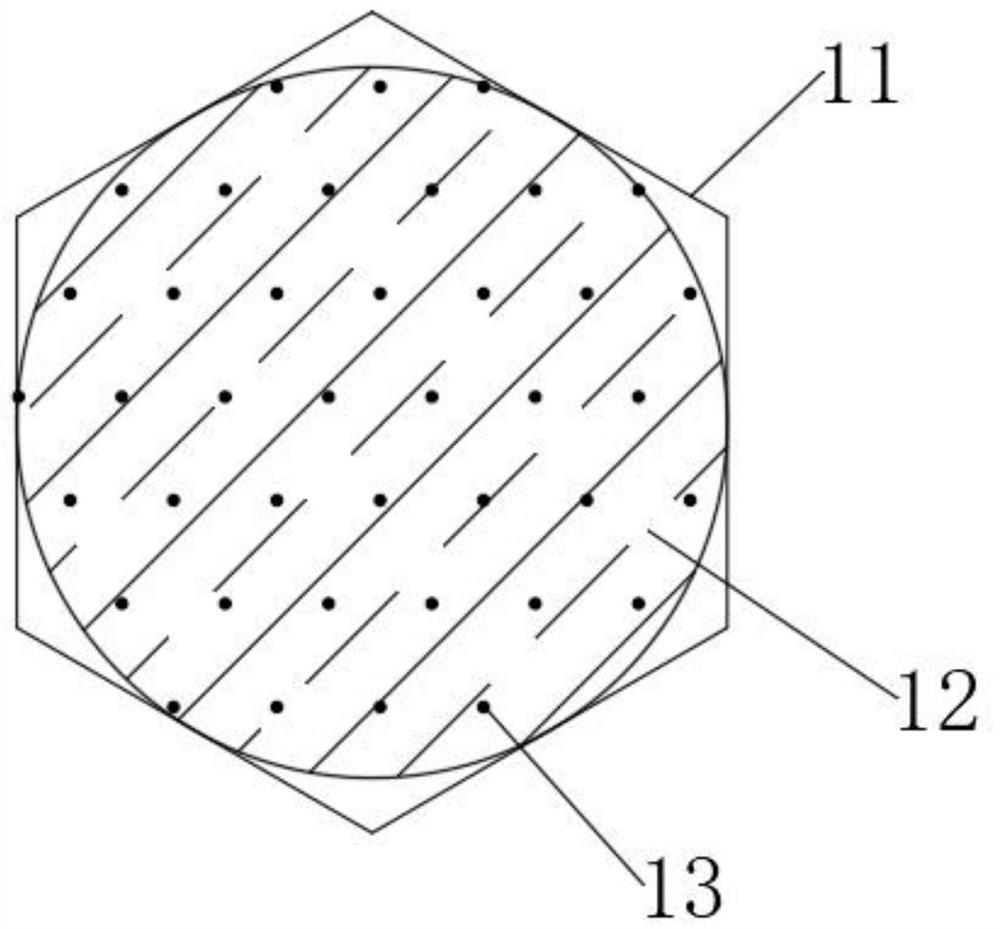

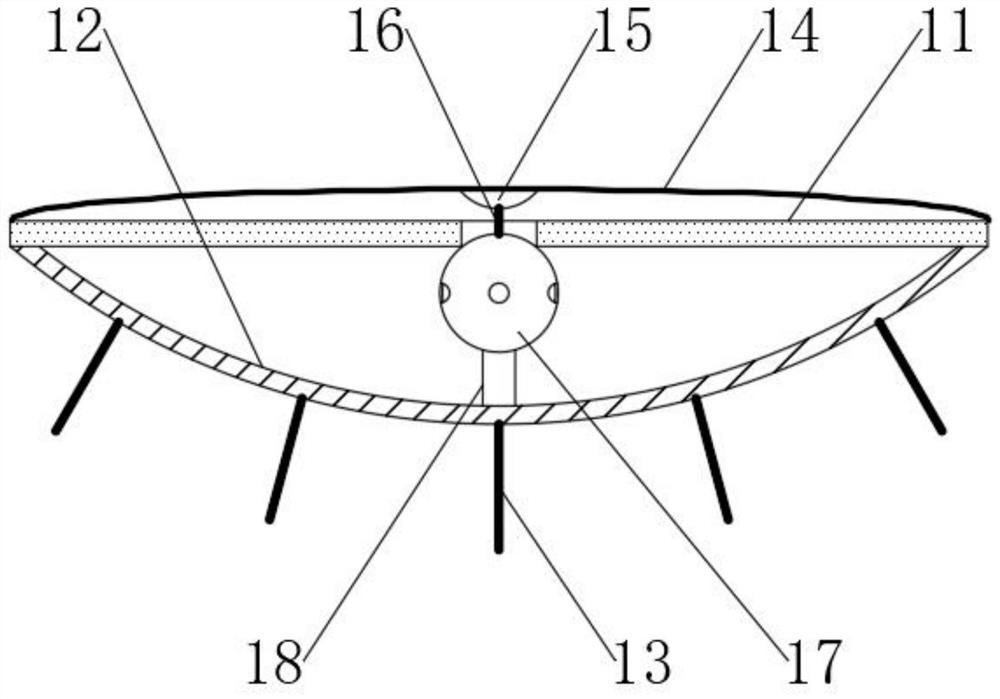

[0049] see figure 1 , a preparation process of self-encapsulated isolated plastic particles, comprising the following steps:

[0050] S1. Weigh the following raw materials in parts by weight according to the formula: 100 parts of plastic substrate, 16 parts of talcum powder, 2 parts of calcium stearate, 1 part of carbon black, 2 parts of nano-titanium dioxide, 2 parts of plasticizer, antioxidant 2 parts, 0.5 parts of flame retardant, stirred at 105-115°C for 100 minutes, the stirring speed is 500r / min, after mixing evenly, a mixture is obtained, which is set aside;

[0051] S2. Take the mixed material and transport it to the barrel of the twin-screw extruder, heat it to 150°C for melt blending, the temperature of the new head on the extruder is 240°C, and the screw speed is 120r / min;

[0052] S3, then put the coating sheet 1 evenly through the front of the new machine head, and it migrates to the wall under the action of the magnetic field inside the molten material, and is e...

Embodiment 2

[0065] see figure 1 , a preparation process of self-encapsulated isolated plastic particles, comprising the following steps:

[0066] S1. Weigh the following raw materials in parts by weight according to the formula: 110 parts of plastic substrate, 18 parts of talcum powder, 3 parts of calcium stearate, 2 parts of carbon black, 4 parts of nano-titanium dioxide, 3 parts of plasticizer, antioxidant 3 parts, 1 part of flame retardant, stirred at 110°C for 110 minutes at a stirring speed of 550r / min, mixed evenly to obtain a mixture, and set aside;

[0067] S2. Take the mixed material and transport it to the barrel of the twin-screw extruder, heat it to 160°C for melt blending, the temperature of the new head on the extruder is 245°C, and the screw speed is 135r / min;

[0068] S3, then put the coating sheet 1 evenly through the front of the new machine head, and it migrates to the wall under the action of the magnetic field inside the molten material, and is extruded together with...

Embodiment 3

[0073] see figure 1 , a preparation process of self-encapsulated isolated plastic particles, comprising the following steps:

[0074] S1. Weigh the following raw materials in parts by weight according to the formula: 120 parts of plastic substrate, 20 parts of talcum powder, 4 parts of calcium stearate, 3 parts of carbon black, 6 parts of nano-titanium dioxide, 4 parts of plasticizer, antioxidant 5 parts, 1.5 parts of flame retardant, stirred at 115°C for 120 minutes, with a stirring speed of 600r / min, mixed evenly to obtain a mixture, and set aside;

[0075] S2. Take the mixed material and transport it to the barrel of the twin-screw extruder, heat it to 170°C for melt blending, the temperature of the new head on the extruder is 250°C, and the screw speed is 150r / min;

[0076] S3, then put the coating sheet 1 evenly through the front of the new machine head, and it migrates to the wall under the action of the magnetic field inside the molten material, and is extruded togethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com