Soil heavy metal removal composite material and preparation method and application thereof

A technology of composite materials and heavy metals, applied in the restoration of polluted soil, etc., can solve the problems of high cost, change of soil properties, deterioration, etc., and achieve the effect of complete removal and easy degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

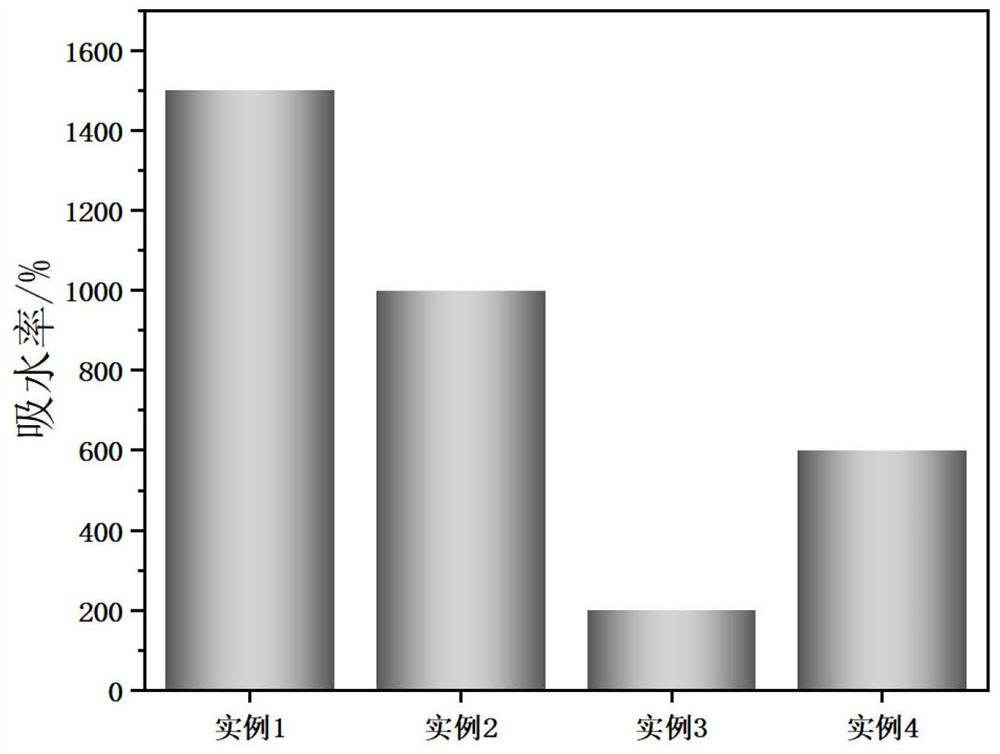

Embodiment 1

[0042] (1) At room temperature, take 0.5g carboxymethyl chitosan, add 3.8g acrylic acid and 5ml deionized water, stir mechanically at 800rpm until completely dissolved.

[0043] (2) At a stirring speed of 800rpm, add 2g of sodium hydroxide to adjust the degree of neutralization of the acrylic acid monomer. After cooling, add 30μl of N,N,N',N'-tetramethyl-1,2-ethylenediamine, 0.001g of N,N'-methylenebisacrylamide, 1.5g of 500nm ferric oxide and 0.2g of potassium persulfate, nitrogen gas was introduced, and the temperature was adjusted to 80°C for polymerization reaction. After 3 hours of reaction, the product was taken out and poured into 10 Settled in cold ethanol with double vigorous stirring, filtered the precipitate, washed with deionized water and ethanol three times alternately, dried in vacuum at 60°C for 24 hours, and obtained double-network superabsorbent resin;

[0044] (3) After crushing the above-mentioned double-network superabsorbent resin and passing it through a...

Embodiment 2

[0047] (1) At room temperature, take 0.5 g of sodium alginate, add 3.8 g of acrylic acid and 5 ml of deionized water, and stir mechanically at 800 rpm until completely dissolved.

[0048](2) While stirring at 800rpm, add 2g of sodium hydroxide to adjust the degree of neutralization of the acrylic acid monomer. After cooling, add 30μl of N,N,N',N'-tetramethyl-1,2-ethylenediamine, 0.001g of N,N'-methylenebisacrylamide, 1.5g of 500nm ferric oxide and 0.2g of potassium persulfate, nitrogen gas was introduced, and the temperature was adjusted to 80°C for polymerization reaction. After 3 hours of reaction, the product was taken out and poured into 10 Settled in cold ethanol with double vigorous stirring, filtered the precipitate, washed with deionized water and ethanol three times alternately, dried in vacuum at 60°C for 24 hours, and obtained double-network superabsorbent resin;

[0049] (3) After crushing the above-mentioned double-network superabsorbent resin and passing it throu...

Embodiment 3

[0052] (1) At room temperature, take 1.0 g of carboxymethyl chitosan, add 3.8 g of acrylic acid and 5 ml of deionized water, and stir mechanically at 800 rpm until completely dissolved.

[0053] (2) While stirring at 800rpm, add 2g of sodium hydroxide to adjust the degree of neutralization of the acrylic acid monomer. After cooling, add 30μl of N,N,N',N'-tetramethyl-1,2-ethylenediamine, 0.001g of N,N'-methylenebisacrylamide, 1.5g of 500nm ferric oxide and 0.2g of potassium persulfate, nitrogen gas was introduced, and the temperature was adjusted to 80°C for polymerization reaction. After 3 hours of reaction, the product was taken out and poured into 10 Settled in cold ethanol with double vigorous stirring, filtered the precipitate, washed with deionized water and ethanol three times alternately, dried in vacuum at 60°C for 24 hours, and obtained double-network superabsorbent resin;

[0054] (3) After crushing the above-mentioned double-network superabsorbent resin and passing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com