FeCoNiIrRu high-entropy nanoparticle catalytic material applied to acidic oxygen evolution reaction and preparation method of FeCoNiIrRu high-entropy nanoparticle catalytic material

A nanoparticle and catalytic material technology, applied in electrolytic components, electrodes, electrolytic process, etc., can solve the problems of limited commercial application, inapplicability to acidic environment, high price, etc., and achieve high acidic oxygen evolution reaction activity and stability, The effect of enhancing the electron transport rate and improving the catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

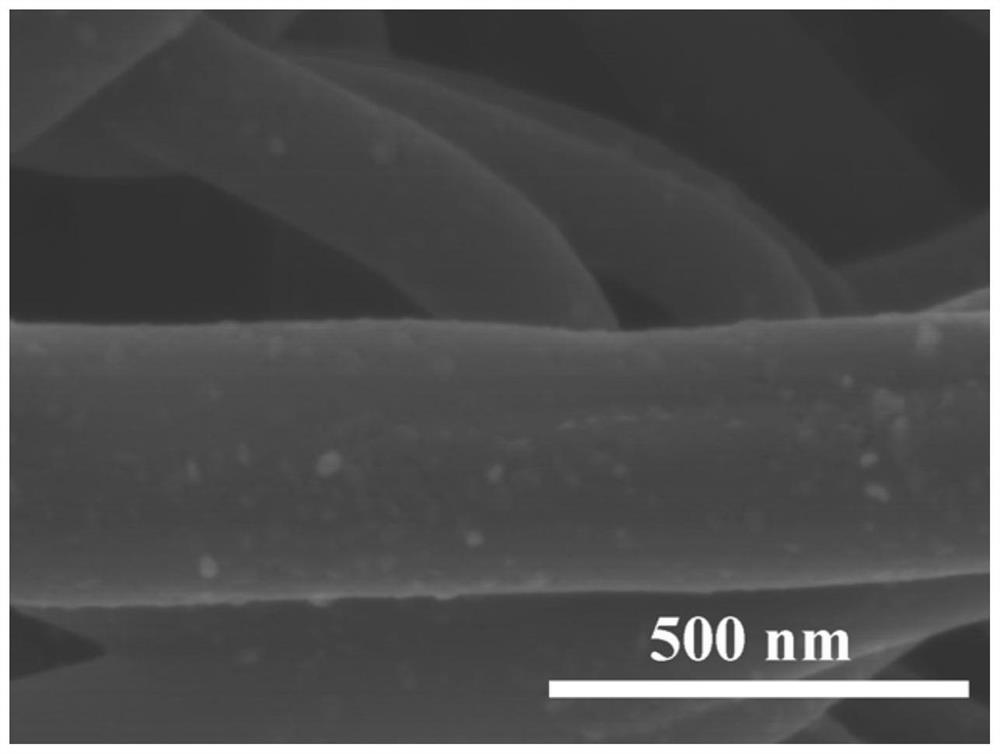

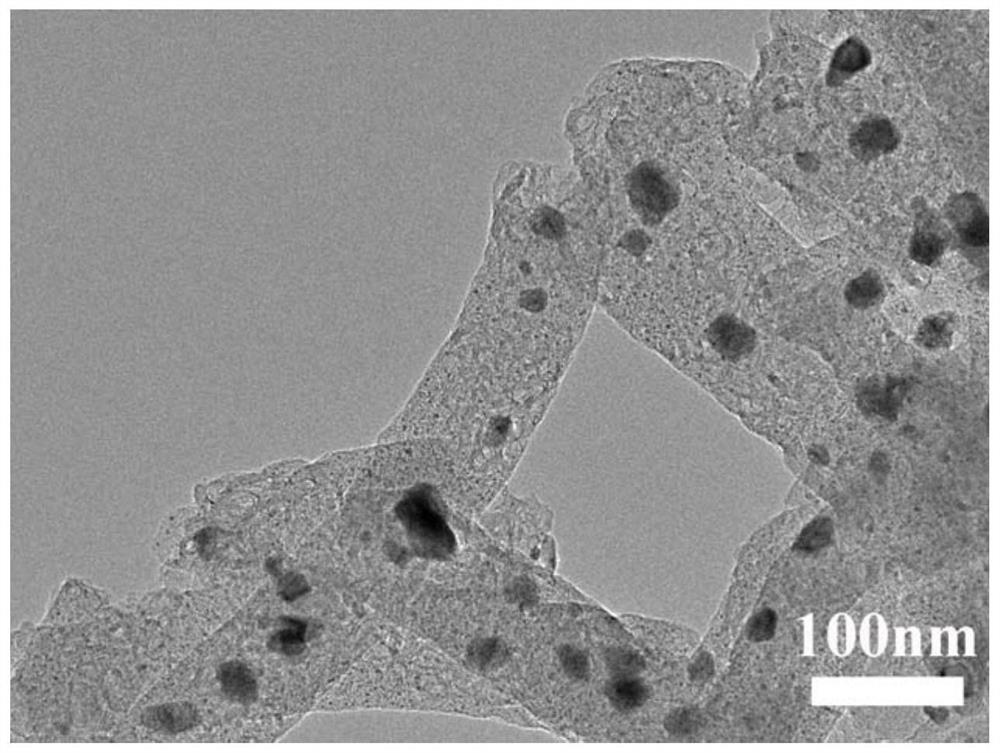

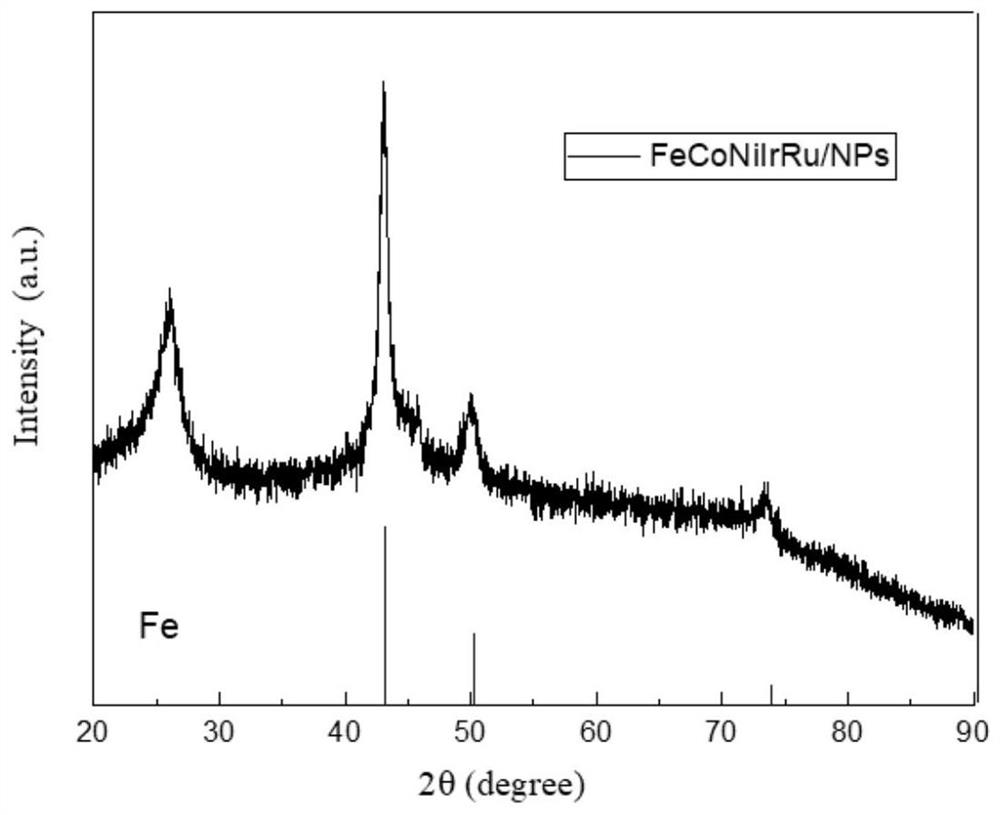

[0047] (1) getting 0.2mmol iron chloride, 0.2mmol cobalt chloride, 0.2mmol nickel chloride, 0.2mmol iridium chloride and 0.2mmol ruthenium chloride to join in 15g mass fraction is the DMF / ethanol of the polyvinylpyrrolidone of 13wt% ( Mass ratio 1:1) in the solution (the total molar concentration corresponding to the metal salt is respectively 0.067mmol / g), evenly stirred by magnetic force, and then the solution is spun by electrospinning, and the spinning voltage is controlled to be 18KV, The distance from the drum of the receiving device to the spinning needle tip was 16 cm, and the flow rate of the solution was 0.2 mL / min to obtain a FeCoNiIrRu / PVP nanofiber membrane.

[0048] (2) Put 0.2 g of the prepared FeCoNiIrRu / PVP nanofiber membrane into a corundum boat and place it in the middle of the tube furnace. First, the temperature was raised to 200° C. at a heating rate of 5° C. / min, and the pre-oxidation was carried out by keeping the temperature in an air atmosphere for 3 ...

Embodiment 2

[0057] Embodiment 2 explores the influence of calcination temperature on catalytic material

[0058] Step (1) is identical with embodiment 1;

[0059] Step (2): Put 0.2g of the prepared FeCoNiIrRu / PVP nanofiber membrane into the corundum boat and place it in the middle of the tube furnace. First, the temperature was raised to 200° C. at a heating rate of 5° C. / min, and the pre-oxidation was carried out by keeping the temperature in an air atmosphere for 3 hours. After the heat preservation is completed, the temperature is raised to 900 or 1100° C. at a rate of 5° C. / min under an argon atmosphere, and the temperature is maintained for 3 hours under an inert atmosphere. After the heat preservation, the temperature was naturally cooled down to room temperature under an inert gas atmosphere, and FeCoNiIrRu / NPs-900 and FeCoNiIrRu / NPs-1100 electrolytic water catalytic materials were obtained respectively.

[0060] According to the method in Example 1, the acidic oxygen evolution p...

Embodiment 3

[0062] Example 3 explores the influence of metal salt dosage ratio conditions on catalytic materials

[0063] Step (1): With reference to Example 1, the mol ratio of ferric chloride, cobalt chloride, nickel chloride, iridium chloride and ruthenium chloride is replaced by 2:2:2:1:3 (0.2mmol chloride iron, 0.2mmol cobalt chloride, 0.2mmol nickel chloride, 0.1mmol iridium chloride and 0.3mmol ruthenium chloride), or 2:2:2:3:1 (0.2mmol iron chloride, 0.2mmol cobalt chloride, 0.2mmol nickel chloride, 0.3mmol iridium chloride and 0.1mmol ruthenium chloride), or 2:2:2:3:3 (0.2mmol ferric chloride, 0.2mmol cobalt chloride, 0.2mmol nickel chloride, 0.3mmol iridium chloride and 0.3mmol ruthenium chloride), and other conditions remain unchanged, Fe 2 co 2 Ni 2 Ir 1 Ru 3 / PVP nanofiber membrane, Fe 2 co 2 Ni 2 Ir 3 Ru 1 / PVP nanofiber membrane and Fe 2 co 2 Ni 2 Ir 3 Ru 3 / PVP nanofiber membrane.

[0064] Step (2) is identical with embodiment 1, makes Fe respectively 2 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com