Hollow-structure ferrous sulfide (at) carbon in-situ composite material and preparation method and application thereof

An in-situ composite material and ferrous sulfide technology, applied in structural parts, electrochemical generators, active material electrodes, etc., can solve the problem of powdering and shedding volume changes of graphite negative electrode materials, excessive potassium ion volume, and poor cycle stability and other problems, to achieve the effect of low cost, cheap and easy-to-obtain raw materials, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

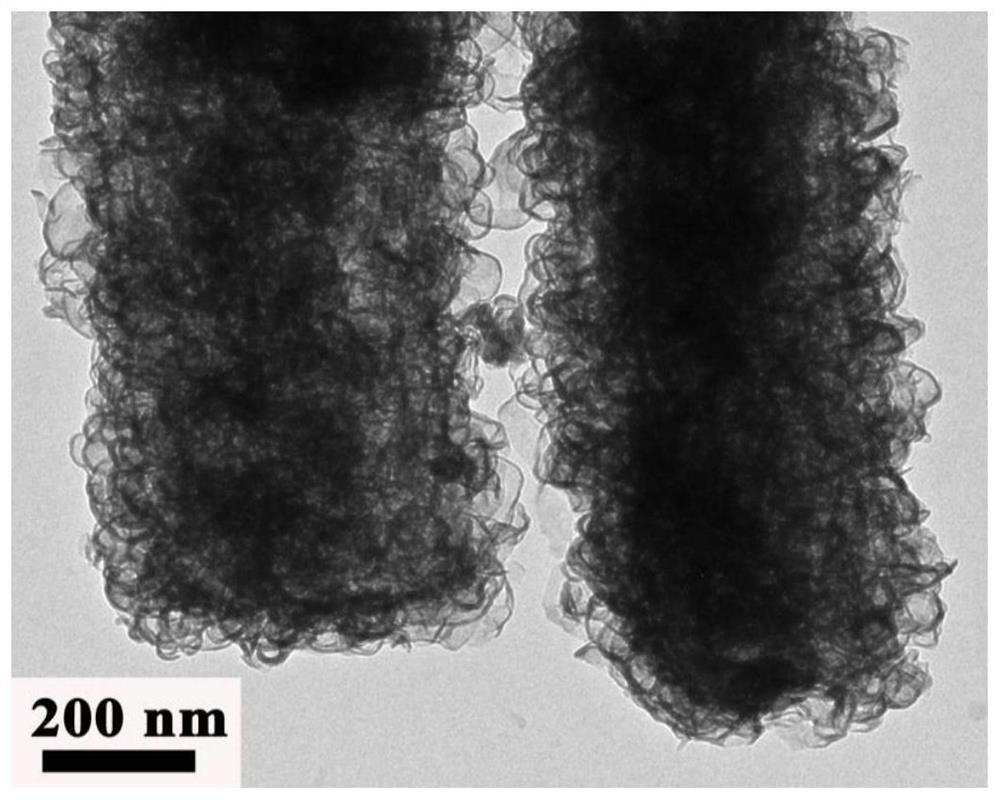

[0031] Preparation of hollow structure ferrous sulfide@carbon in situ composite:

[0032] (1) Weigh 1.0g of ferrous sulfate, stir and dissolve in 30mL of water, then add 800mg of glycerin, stir to dissolve, add 1mol / L ammonia water dropwise at a rate of 1mL / min, stop the dropwise addition after white precipitation appears in the solution, and stir at room temperature 2h, suction filtration, washing, and drying at 50°C to obtain a solid nanorod-shaped iron hydroxide-glycerol precursor;

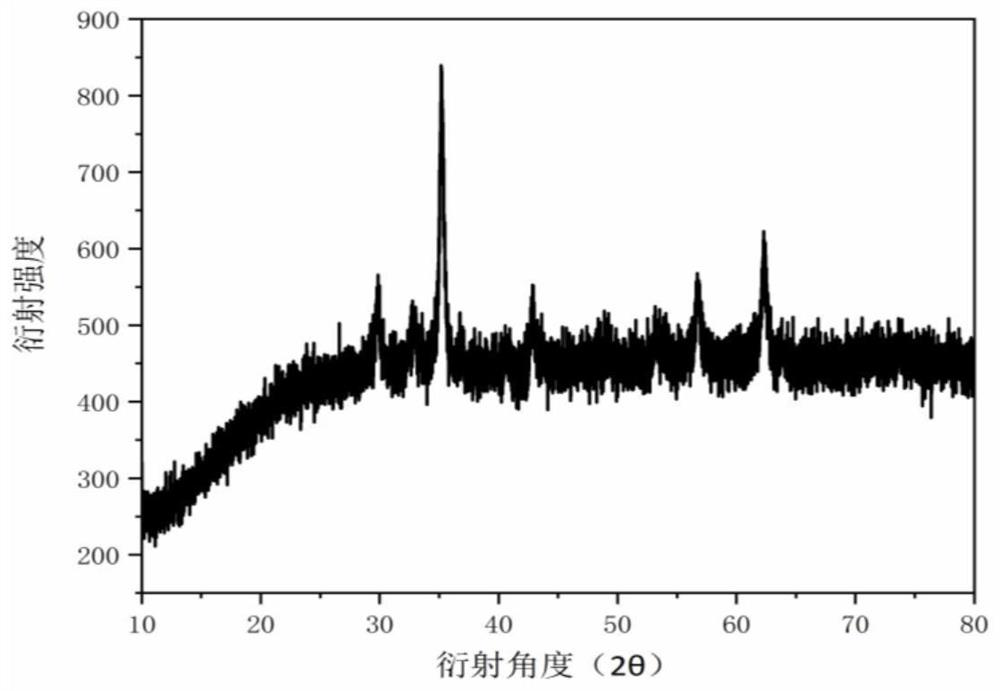

[0033] (2) Weigh 200mg of the precursor of step (1), add 30mL of water, ultrasonically disperse until uniform, add 570mg of cysteine, stir to dissolve, transfer to a hydrothermal kettle, 150°C hydrothermal reaction for 12h, and naturally cool To room temperature, the product was black, centrifuged, washed with ethanol and deionized water, and dried in vacuum at 60°C. The obtained powder was placed in a porcelain boat, placed in a muffle furnace with nitrogen, and calcined at 600°C for 2 hours. ...

Embodiment 2

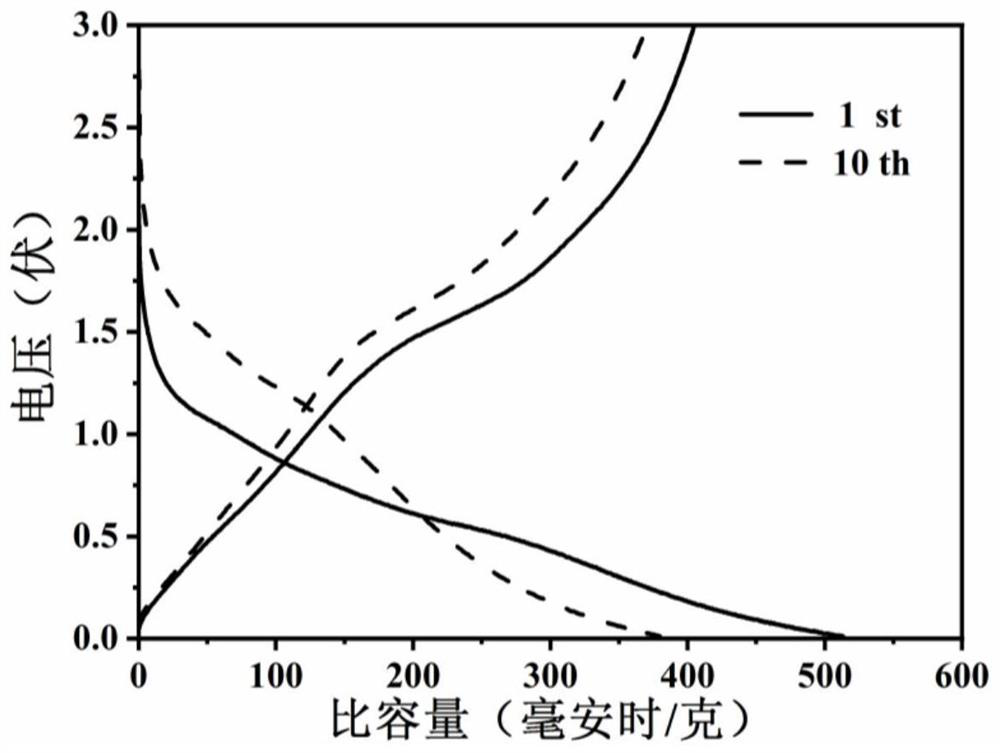

[0038] The ferrous sulfide@carbon in-situ composite material with a hollow rod-shaped structure prepared in Example 1 was used as an electrode active material in an energy storage battery. Mix 800 mg of ferrous sulfide@carbon in-situ composite material with a hollow rod-like structure, 100 g of acetylene black, and 100 g of polyvinylidene fluoride, add 1 g of nitrogen methyl pyrrolidone, and spread the stirred slurry on aluminum foil at 100 degrees drying. Cut out 1 cm original pieces of dendrites. The diaphragm is made of non-woven fabric, the counter electrode is metal potassium sheet, and the electrolyte is potassium hexafluorophosphate dissolved in diethyl carbonate solvent with a concentration of 1mol / L. A 2016 button battery is assembled in an anhydrous and oxygen-free glove box to obtain potassium Ion button battery.

[0039] The potassium ion button battery prepared in this embodiment was charged and discharged at a rate of 0.1C between 0.1 volts and 3.5 volts. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com