Beneficiation method for complex and difficult-to-treat copper-sulfur sulfide ore

A technology of sulfur sulfide ore and beneficiation method, which is applied in flotation, solid separation and other directions, can solve the problems of low recovery rate of associated precious metals, difficult treatment of beneficiation wastewater, and difficult recovery of pyrite, so as to reduce electrochemical corrosion and reduce Activation, easily degradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

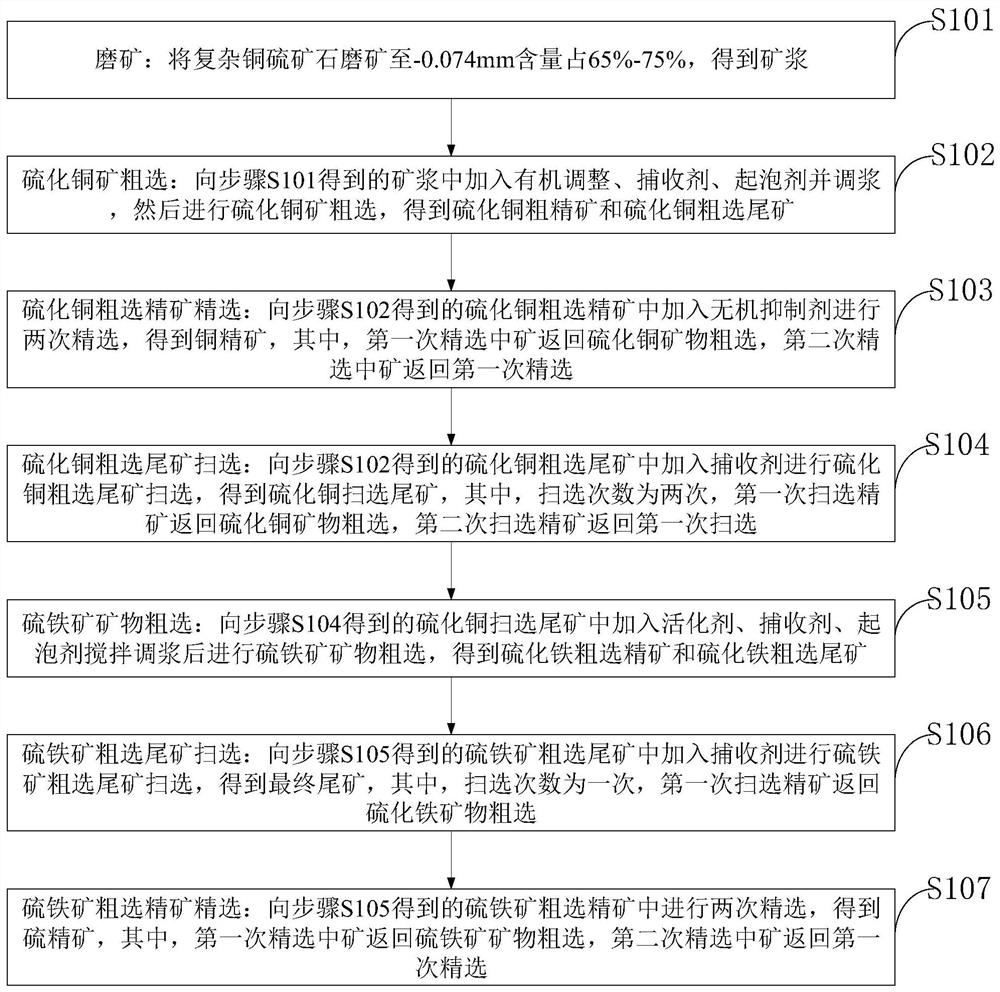

Method used

Image

Examples

Embodiment 1

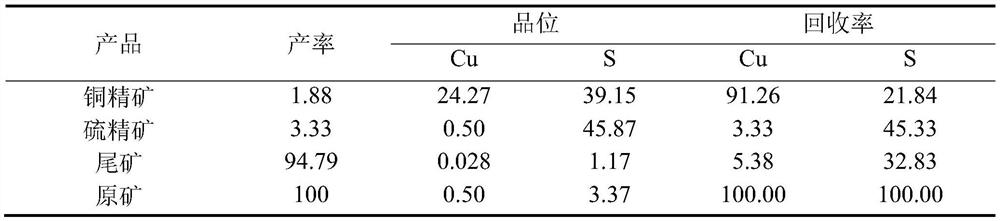

[0041]A copper ore original mineral cu 0.50%, sulfur is 3.37%, copper, sulfur is the main price, and the copper-containing mineral contained in the ore is mainly brass mine, sulfur-containing mineral is Huangding and magnetic 黄; The ore grinding to -0.074mm accounts for 68%, and the combination of tannic acid and 1,2-benzene phenol is added to the abrasive slurry. 60 g / t, O-isopropyl-N-ethyl sulfur The combined collectors of amtrine and mercaptocetate and mercaptobenzothiazole are 40 g / t, 2 oils 28g / t, and after generous copper sulfide coarse selection, obtaining sulfide coarse selection and roughing; The first selection of 100 g / t lime was added to the copper sulfide coarse-selected concentrate, and the first selection of medium mine returned to the copper sulfide mineral, and the first selection was added to 50 g / t lime for the second time. Selected, the final copper concentrate, the second selection of medium ore returned to the first selection; O-isopropyl-N-ethylthi...

Embodiment 2

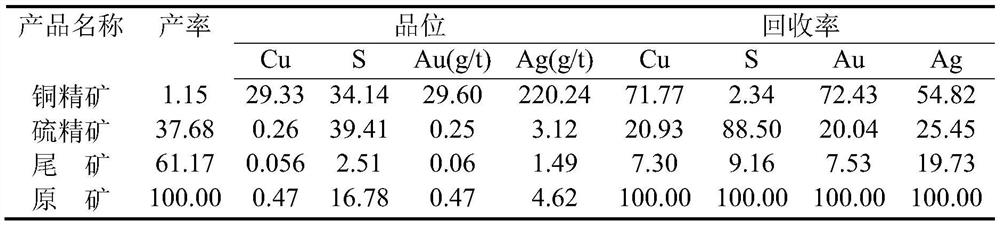

[0045] A copper ore original ore Cu 0.47, 16.78% sulfur, metal minerals in the ore include brass mine, magnetic iron ore, gum-shaped yellow iron mine; 75% of the ore grinding to -0.074mm, to the wear slurry The combination of tannic acid and 1,2-benzene phenol is added sequentially added 100 g / t, O-isopropyl-N-ethylthioceranslate and mercaptobenzothiazole combined collectors 40g / t, 2 oil 28g / t, and then sulfide copper sulfide is coarsely selected, and the copper sulfide is coarsely selected concentrate and coarse selection; 200g / t lime is added to the sulfurized coarse selection of concentrates for the first time Selected, the first selection of medium mine returned to the copper sulfide mineral coarse selection, and the first selection was added to the second selection of 100 g / t lime for the second selection, and the second selection of medium mine returned. The first selection; the combination of O-isopropyl-N-ethylthioceranside and mercaptopenzothiazole is added to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com