Modified expandable graphite, coating film for cable fire prevention and explosion prevention and production method thereof

A technology of expanded graphite and coating film, which is applied in the direction of insulating cables, chemical instruments and methods, cables, etc., and can solve problems such as lack of adhesion of cables, poor fire resistance of fireproof materials, and easy aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

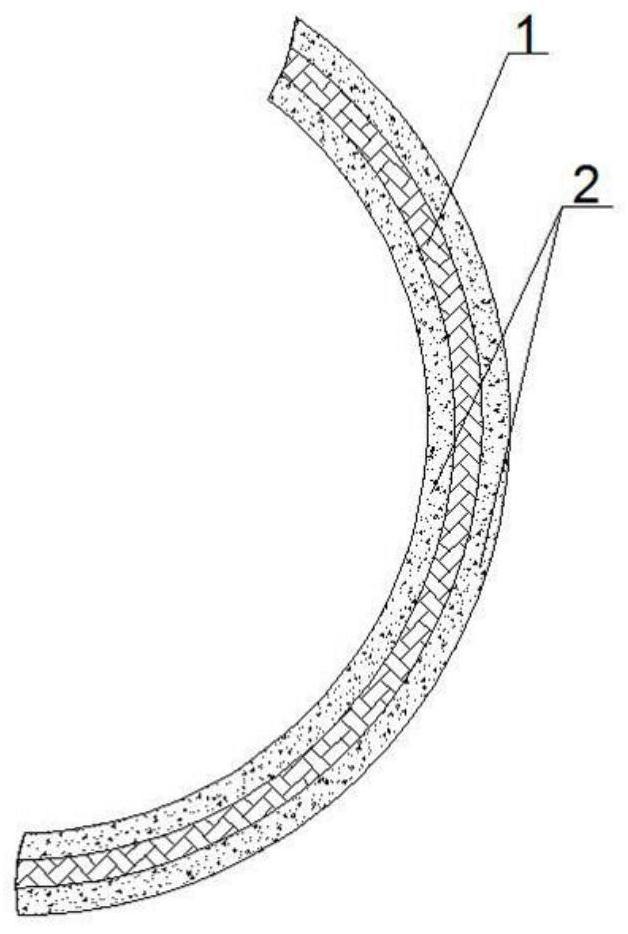

Image

Examples

Embodiment 1

[0032] A modification method of expandable graphite, specifically comprising the following steps:

[0033] 1) Set the temperature of the puffing furnace to 350°C, send the expandable graphite into the puffing furnace, and puff it in the puffing furnace for 6 seconds to obtain pre-expanded graphite worms;

[0034] Expandable graphite is prepared from natural flake graphite through oxidative intercalation reaction. It is a conventional chemical raw material and can be purchased and used by itself, or prepared and used by the method of the prior art.

[0035] The intercalants contained in expandable graphite, the driving force generated by vaporization under high temperature conditions can open the graphite sheets, so the expansion temperature is an important parameter affecting the structure of expanded graphite. From 300-900 ° C, the expansion of expanded graphite The volume will gradually increase with the increase of the expansion temperature. This shows that with the increas...

Embodiment 2

[0043]A modification method of expandable graphite, specifically comprising the following steps:

[0044] 1), set the temperature of the puffing furnace to 450°C, send the expandable graphite into the puffing furnace, and puff it in the puffing furnace for 3 seconds to obtain pre-expanded graphite worms;

[0045] 2), mixing pre-expanded graphite worms with water, and then adding a dispersant for ultrasonic dispersion to obtain a pre-expanded graphite worm dispersion;

[0046] The mass ratio of the pre-expanded graphite worms to water is 1:70, and the added amount of the dispersant is 2% of the weight of the pre-expanded graphite worms. The dispersant can be a conventional dispersant, such as active calcium phosphate and sodium polyacrylate.

[0047] 3), adding basic copper carbonate to the pre-expanded graphite worm dispersion, and continuing ultrasonic dispersion to obtain the target dispersion;

[0048] The addition amount of basic copper carbonate is 10% of pre-expanded g...

Embodiment 3

[0051] A modification method of expandable graphite, specifically comprising the following steps:

[0052] 1) Set the temperature of the puffing furnace to 400°C, send the expandable graphite into the puffing furnace, and puff it in the puffing furnace for 5 seconds to obtain pre-expanded graphite worms;

[0053] 2), mixing pre-expanded graphite worms with water, and then adding a dispersant for ultrasonic dispersion to obtain a pre-expanded graphite worm dispersion;

[0054] The mass ratio of the pre-expanded graphite worms to water is 1:60, and the added amount of the dispersant is 1% of the weight of the pre-expanded graphite worms. The dispersant can be a conventional dispersant, such as active calcium phosphate and sodium polyacrylate.

[0055] 3), adding basic copper carbonate to the pre-expanded graphite worm dispersion, and continuing ultrasonic dispersion to obtain the target dispersion;

[0056] The addition amount of basic copper carbonate is 60% of pre-expanded g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com