Treatment method of high-salt and high-ammonia-nitrogen degradation-resistant organic wastewater

A treatment method, a technology for organic wastewater, applied in the direction of biological treatment adjustment methods, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of degradation main reaction efficiency, affecting organic matter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

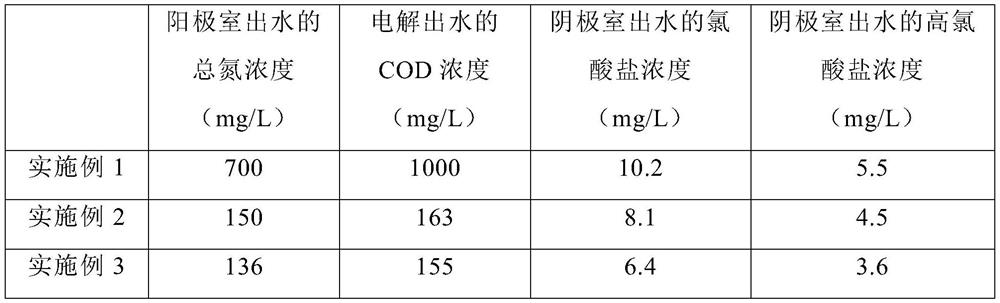

Embodiment 1

[0073] The treatment method of the high-salt and high-ammonia-nitrogen refractory organic wastewater described in this embodiment comprises the following steps:

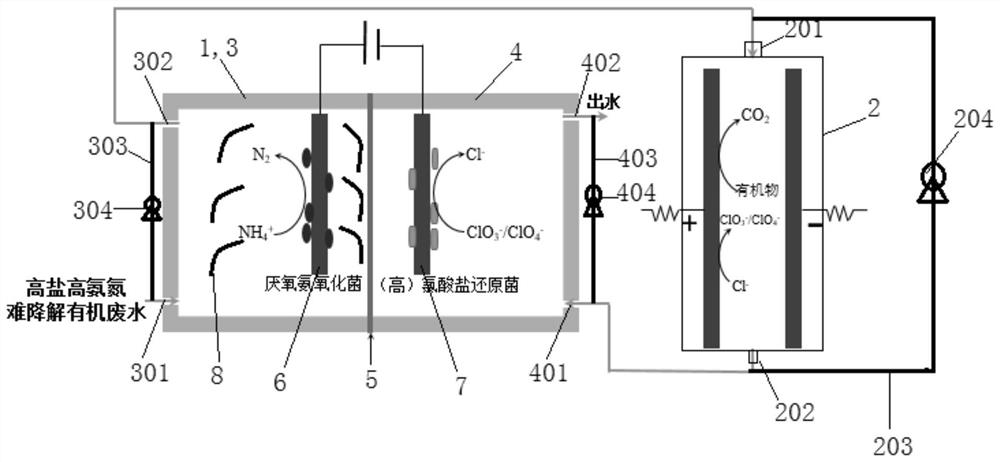

[0074] (1) The waste water enters the anode chamber of the microbial electrolytic cell for anaerobic ammonium oxidation autotrophic denitrification, the anode electrode is a carbon fiber electrode, and the anammox bacteria are attached to the surface and pores of the carbon fiber electrode to grow, and the waste water is discharged from the anode chamber Bottom input, top output, cyclically flow through the carbon fiber electrode, and perform autotrophic denitrification under the biochemical action of anammox bacteria;

[0075] The carbon fiber electrode has a specific surface area of 500m 2 / g, the pore size is 20 μm, and the biofilm thickness is 10 μm;

[0076] The volume of the anode chamber is 450m 3 , the electrode mass required per unit volume is 2g, the operating pH value in the anode chamber is 7, the ope...

Embodiment 2

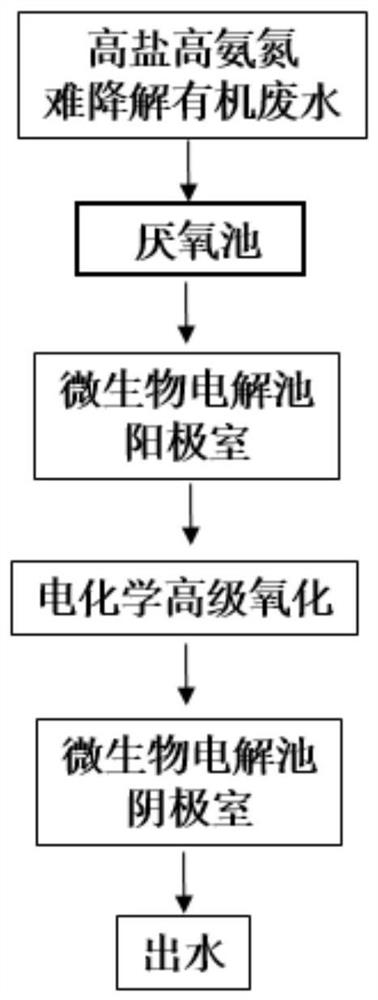

[0085] In the treatment method of high-salt, high-ammonia-nitrogen refractory organic wastewater described in this embodiment, such as figure 1 As shown, anaerobic treatment is added before the anode of the microbial electrolysis cell treats wastewater:

[0086] The wastewater first enters the anaerobic tank to degrade macromolecular organic matter, consume high-concentration organic carbon, and completely remove degradable organic matter as much as possible, creating favorable water inflow conditions for subsequent autotrophic denitrification treatment. At the same time, the ammonification reaction is carried out in the anaerobic tank to convert most of the organic nitrogen into ammonium nitrogen;

[0087] The effective volume of the anaerobic tank is 1200m 3 , the hydraulic retention time is 4d, and the volume removal load of organic matter is 0.7kg COD / (m 3 d), the COD concentration of the effluent of the anaerobic tank is 250mg / L;

[0088] The other steps and processing...

Embodiment 3

[0090] In the treatment method of high-salt, high-ammonia-nitrogen refractory organic wastewater described in this embodiment, the anode electrode of the anode chamber of the microbial electrolysis cell is a porous graphene electrode, and other steps and process conditions are the same as in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com