a ngqd/fe 2 o 3 /Graphene foam composite film and its preparation method and application

A graphene foam, composite film technology, applied in chemical instruments and methods, instruments, luminescent materials, etc., can solve the problems of reducing the stability and working life of gas sensors, poor repeatability, high energy consumption, etc., to improve electron transmission. Capability and gas-sensing activity, low operating temperature, the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

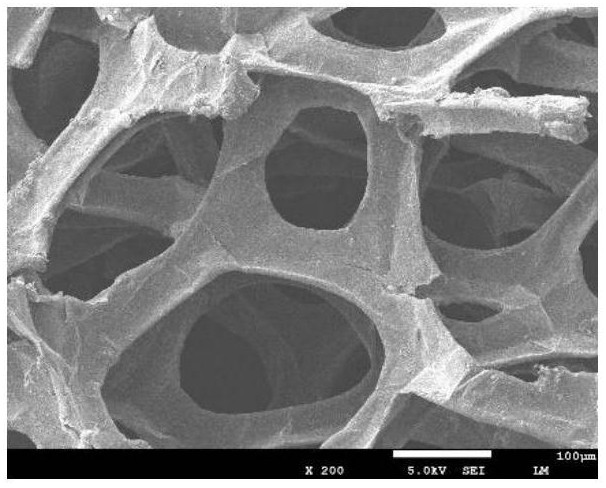

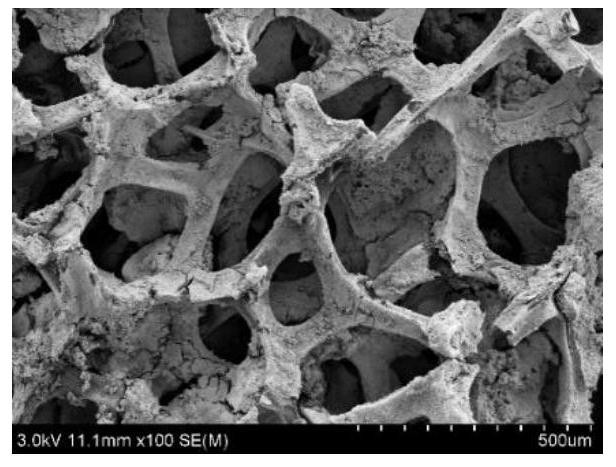

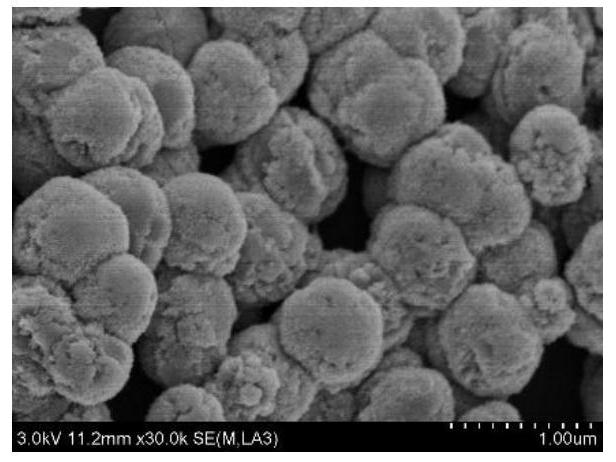

[0026] (1) Clean the nickel foam with acetone, and weld it on the sensor device, wherein the sensor device is: a silicon substrate, silicon dioxide is deposited on the silicon substrate, then a titanium layer and a platinum layer are deposited, and finally the surface is etched Platinum interdigitated electrode array, the width of each platinum interdigitated finger is 10 μm, the length is 1 mm, the interdigital electrode spacing is 8 μm, and the overlap between interdigital fingers is 800 μm. The sensor device welded with nickel foam is placed in a tubular Furnace, 22sccm H in tube furnace 2 and 53 sccm Ar environment, and ramped up to 1000 °C at a rate of 10 °C per min, held for 50 min, and then passed through bubbling H at ambient pressure 2 / Ar gas mixture to introduce ethanol vapor into the quartz tube, after 30 min, turn off the ethanol vapor, and cool the system to room temperature, etched the nickel substrate into a three-dimensional graphene foam with deionized water ...

Embodiment 2

[0036] (1) Clean the nickel foam with acetone, and weld it on the sensor device, wherein the sensor device is: a silicon substrate, silicon dioxide is deposited on the silicon substrate, then a titanium layer and a platinum layer are deposited, and finally the surface is etched Platinum interdigitated electrode array, the width of each platinum interdigitated finger is 10 μm, the length is 1 mm, the interdigital electrode spacing is 8 μm, and the overlap between interdigital fingers is 800 μm. The sensor device welded with nickel foam is placed in a tubular Furnace, 55sccm H in tube furnace 2 and 110 sccm Ar environment, and ramped up to 1000 °C at a rate of 10 °C per min, held for 50 min, and then passed through bubbling H at ambient pressure 2 / Ar gas mixture to introduce ethanol vapor into the quartz tube, after 30 min, turn off the ethanol vapor, and cool the system to room temperature, etched the nickel substrate into a three-dimensional graphene foam with deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com