Lithium battery coated metal lithium negative electrode material and preparation method thereof

A technology of negative electrode material and metal lithium, applied in the field of lithium battery coated metal lithium negative electrode material and preparation field, can solve the problems of short cycle life, low Coulomb efficiency, poor safety performance, etc., so as to improve the transportation capacity and improve the cycle performance. , the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

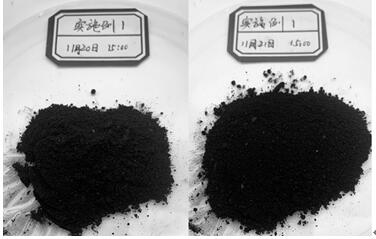

Embodiment 1

[0041] (1) Add lithium shavings to the grinding bowl, then perform wet grinding in an argon-protected glove box, the grinding medium is kerosene, the speed is controlled at 45rpm, grind for 5 hours, remove the oxide film on the surface, and then collect the obtained powder After drying, put it into a vacuum bag and seal it to realize the pretreatment of lithium and obtain lithium powder with a highly active surface;

[0042] (2) Add 85g of lithium powder with high active surface and 35g of amino-functionalized graphene microflakes into the ball mill. Ball milling under the protection of argon for 2.5 hours, the ball milling is dry ball milling, the grinding medium is zirconia microspheres, the average diameter is 0.8mm, the ball-material ratio is controlled at 9:1, the speed is controlled at 40rpm, and then the gas source is replaced with argon / Nitrogen mixed gas, the gas flow ratio of argon and nitrogen is 100:5, continue ball milling for 1.5h to obtain composite particles o...

Embodiment 2

[0044] (1) Add lithium shavings to the grinding bowl, then perform wet grinding in an argon-protected glove box, the grinding medium is liquid paraffin, the speed is controlled at 42rpm, grind for 5.5h, remove the oxide film on the surface, and then collect the obtained After the powder is dried, put it into a vacuum bag and seal it to realize the pretreatment of lithium and obtain lithium powder with a high active surface;

[0045] (2) Add 88g of lithium powder with high active surface and 32g of amino-functionalized graphene microflakes into a ball mill. Ball milling under the protection of argon for 2 hours, the ball milling is dry ball milling, the grinding medium is zirconia microspheres, the average diameter is 0.6mm, the ball-to-material ratio is controlled at 8:1, the speed is controlled at 35rpm, and then the gas source is replaced with argon / Mixed gas of nitrogen, the gas flow ratio of argon and nitrogen is 100:3, continue ball milling for 1h to obtain composite par...

Embodiment 3

[0047] (1) Add lithium shavings to the grinding bowl, then perform wet grinding in an argon-protected glove box, the grinding medium is kerosene, the speed is controlled at 48rpm, grind for 4.5h, remove the oxide film on the surface, and then collect the obtained powder After the body is dried, put it into a vacuum bag and seal it to realize the pretreatment of lithium and obtain lithium powder with a high active surface;

[0048] (2) Add 82g of lithium powder with high active surface and 38g of amino-functionalized graphene microflakes into a ball mill. Ball milling under the protection of argon for 3 hours, the ball milling is dry ball milling, the grinding medium is zirconia microspheres, the average diameter is 0.9mm, the ball-to-material ratio is controlled at 10:1, the speed is controlled at 45rpm, and then the gas source is replaced with argon / The mixed gas of nitrogen, the gas flow ratio of argon and nitrogen is 100:8, continue ball milling for 2h, obtain the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com