Polyaryletherketone modifier as well as preparation method and application thereof

A technology of polyaryletherketone and modified products, which is applied in the field of polyaryletherketone modified products and their preparation, can solve problems such as insufficient interface osseointegration, achieve the elimination of stress shielding effect, simple preparation method, and accelerate early osseointegration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

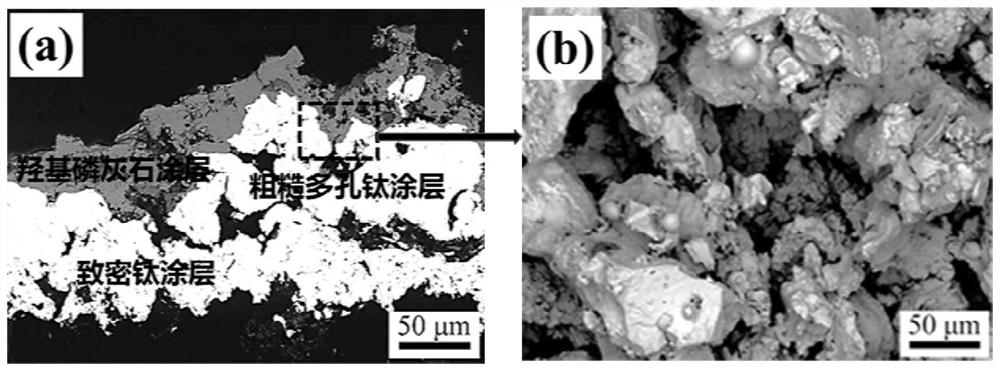

[0077] Correspondingly, the present application provides a method for preparing the modified polyaryletherketone, which may include the following steps: preparing a composite coating on the surface of the polyaryletherketone material.

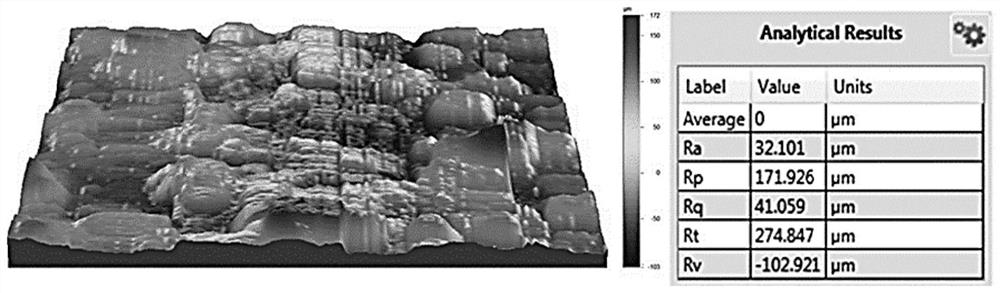

[0078] It is worth noting that the inventors found that although the above-mentioned composite coating can be prepared by using magnetron sputtering technology, micro-arc oxidation technology, sol-gel technology, etc., the equipment required for the above-mentioned technology is complicated, the preparation process is cumbersome, and the price is relatively high. High, and it is difficult to obtain a microstructure coating with high porosity and ultra-high roughness. The plasma spraying process is simple, economical, and can achieve greater overall output. It is the fastest and easiest process to achieve a large pore network and rough surface of the implant. Therefore, in terms of cost / benefit, plasma spraying technology is the most effective p...

Embodiment 1

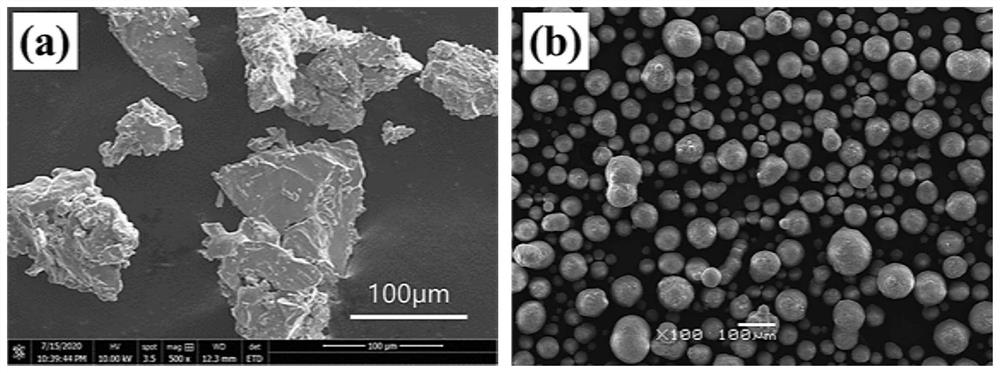

[0096] Use PEEK as the substrate, use 60#SiC to polish the surface, and then use Al 2 o 3 Sandblasting is carried out until the surface roughness is Ra=10-15μm, and then ultrasonic cleaning is carried out with alcohol. The particle size of 200g is d 50 = 32μm and d 50 The sponge titanium powder of about 110 μm is loaded into the powder feeder respectively.

[0097] Put the PEEK matrix into the vacuum chamber and close the vacuum plasma equipment hatch, pump the vacuum to the pressure 40mbar, after pointing the gun, pump the vacuum to the pressure <2mbar, and then pass the plasma jet to the The polyaryletherketone material is preheated.

[0098] Adjust the vacuum plasma spraying parameters to prepare the first titanium coating-priming layer: the spraying pressure is 14KPa; the spray gun power is 30kW, the current is 550A; the working gas Ar flow rate is 45splm, H 2 Air flow is 4slpm. After the flame flow is stable, the particle size is d at a powder feeding rate of 10g / mi...

Embodiment 2

[0102] The difference between this embodiment and embodiment 1 is:

[0103] Adjust the vacuum plasma spraying parameters to prepare the primer titanium coating: the spraying pressure is 10KPa; the spray gun power is 25kW, the current is 580A; the working gas Ar flow rate is 40splm, H 2 The air flow is 2slpm. After the flame flow is stable, the particle size is d at a powder feeding rate of 12g / min. 50 =32μm Ti powder is fed into the plasma flame. The spraying distance is 250mm; the plasma gun moves horizontally at a speed of 1000mm / s, and sprays 6 times.

[0104] Adjust the vacuum plasma spraying parameters to prepare rough porous titanium coating: the spraying pressure is 10KPa, the spray gun power is 25kw, the current is 520A; the working gas Ar flow rate is 40splm, H 2 The air flow is 2slpm. After the flame flow is stable, the particle size is d at a powder feeding rate of 15g / min. 50 = 110μm Ti powder is sent into the plasma flame, the spraying distance is 250mm; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com