Mo-V-Te-Sb-Nb-O catalyst and preparation method and application thereof

A mo-v-te-sb-nb-o, catalyst technology, applied in the field of catalysis, can solve the problem of low performance, and achieve the effect of improving selectivity and yield, excellent stability and catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

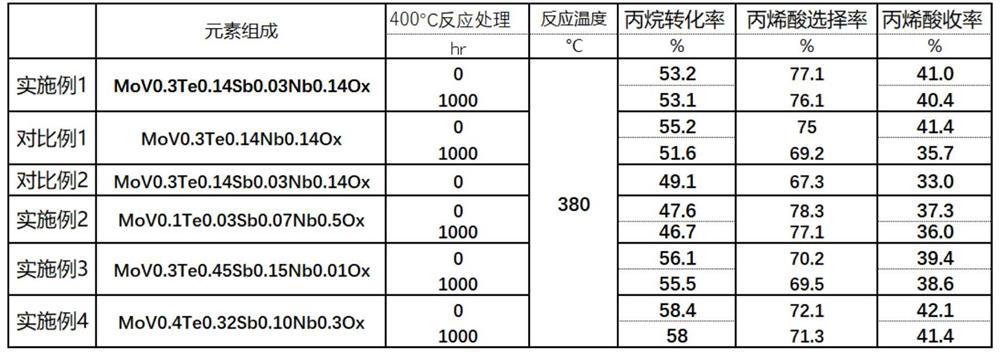

Examples

preparation example Construction

[0019] The preparation method of a kind of Mo-V-Te-Sb-Nb-O catalyst provided by the embodiment of the present invention comprises:

[0020] Depositing at least part of the antimony source onto the metal tellurium particles as the tellurium source to obtain the first raw material;

[0021] reacting the first raw material with a molybdenum source, a vanadium source, and a niobium source in a solvent to obtain a catalyst precursor;

[0022] The catalyst precursor is dried and calcined to prepare a Mo-V-Te-Sb-Nb-O catalyst.

[0023] In some embodiments, the preparation method includes:

[0024] Depositing at least part of the antimony source onto the metal tellurium particles as the tellurium source to obtain the first raw material;

[0025] The first raw material is reacted with the molybdenum source, the vanadium source and the niobium source in a solvent to obtain a slurry containing the catalyst precursor.

[0026] Further, the preparation method specifically includes: addi...

Embodiment 1

[0069] A kind of Mo-Te-Sb-V-Nb series catalyst of this embodiment is prepared by following steps 1)~step 3):

[0070] 1) Mixing and drying: add 370.8g of ammonium tetramolybdate and 65.4g of ammonium metavanadate to 900g of distilled water, stir and dissolve at 80°C, then add liquid A and 576g of ammonia water with a concentration of 2.0wt%, and continue to stir. When the temperature of the temperature drops to 50°C, keep stirring, and add liquid B to obtain a viscous precipitate, keep stirring for 5 minutes, then add 960g of ammonium nitrate to the reaction system, continue stirring, and finally spray dry the obtained liquid into powder.

[0071] Wherein liquid A and liquid B can be prepared by the following methods, including:

[0072] Mix 44.8g of tellurium dioxide, 34.5g of hydrazine and 800g of distilled water, and stir at 80°C for 4 hours and heat reduction to obtain needle-shaped particles containing metal tellurium (needles with an average length of 0.3 μm and an aver...

Embodiment 2

[0087] Embodiment 2 The preparation process of a kind of Mo-Te-Sb-V-Nb series catalyst of this embodiment is basically the same as that of Embodiment 1, the difference is:

[0088] In step 1), the atomic ratios of the vanadium source, tellurium source, antimony source, and niobium source to the molybdenum source are 0.1, 0.01, 0.07, and 0.3, respectively, and the atomic ratio of the tellurium source to the vanadium source is 0.3.

[0089] In step 1), ammonium tetramolybdate and ammonium metavanadate were stirred and dissolved in distilled water at 40° C., then A liquid and 576 g of ammonia water with a concentration of 2.0 wt % were added, and the stirring was continued to maintain the temperature of the reaction system at 40° C. And add liquid B to obtain a viscous precipitate. After continuous stirring, add ammonium nitrate (the molar ratio of ammonium nitrate to molybdenum source is 0.4) in the reaction system, continue stirring, and finally spray-dry the obtained liquid slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com