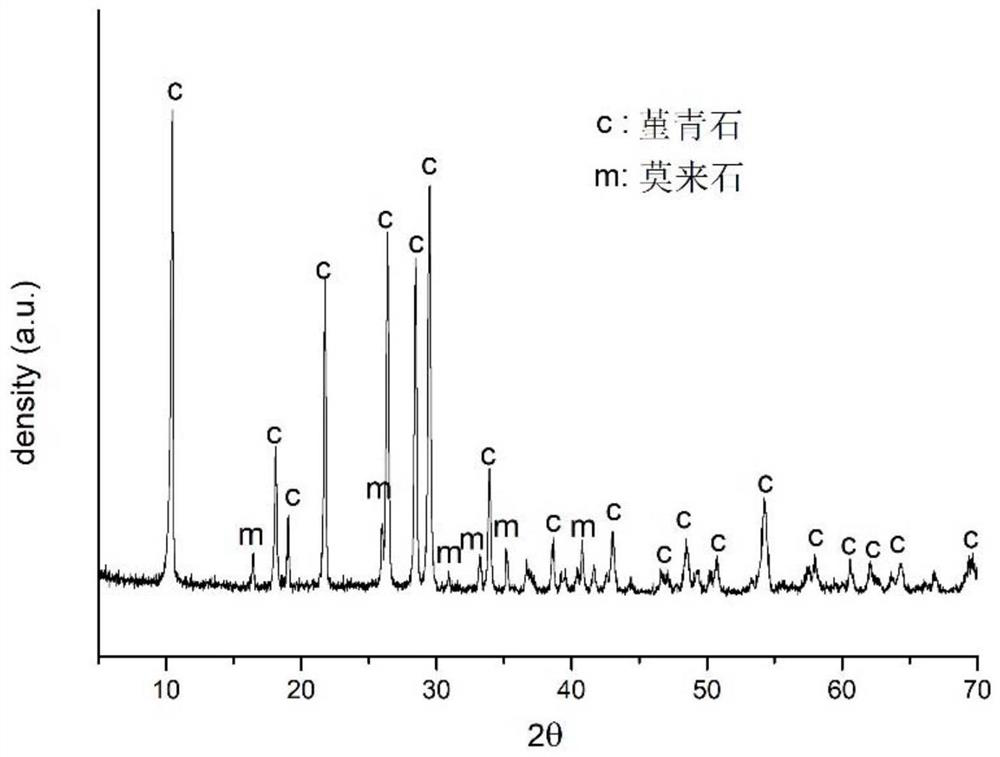

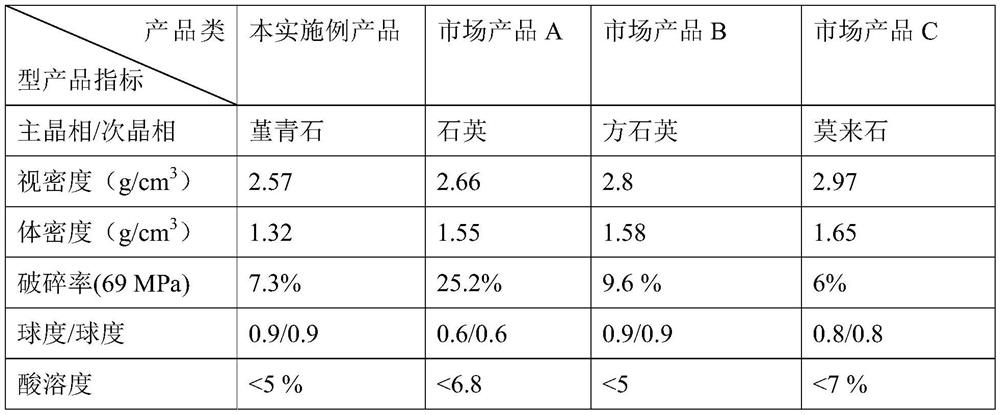

Cordierite-based ultralow-density high-strength petroleum fracturing propping agent and preparation method thereof

A fracturing proppant and ultra-low density technology, which is applied in chemical instruments and methods, earth drilling, clay products, etc., can solve the problems of low strength and difficulty of ceramsite, and achieve high value-added utilization, stable properties, and improved The effect of transport efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation process

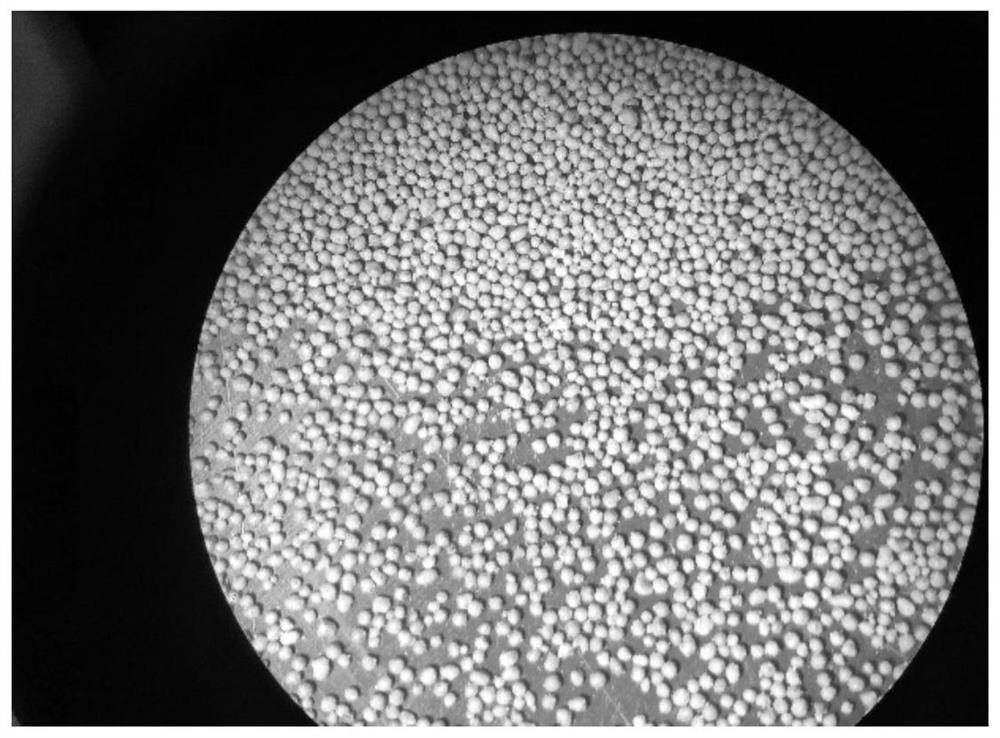

[0027] A cordierite-based ultra-low-density high-strength petroleum fracturing proppant and a preparation method thereof. The raw material formula is as follows: 25% talc, 65% kaolin, 10% high-plasticity clay, all of which are mass fractions. Chemical composition of talc raw materials: 35% by mass of MgO, SiO 2 Mass percentage 49%, Al 2 o 3 Mass percent content 10.8%; loss on ignition 11%; chemical composition of kaolin: Al 2 o 3 Mass fraction 41.2%, SiO 2 Mass percentage 45.7%, Fe 2 o 3 Mass percent content 3.5%; high plasticity clay raw material Al 2 o 3 Mass percentage 21.5%, SiO 2 The mass percentage is 70.8%. The cordierite-based petroleum fracturing proppant was prepared through wet ball milling, spray granulation, rolling ball granulation, green body screening, and high-temperature firing.

[0028] 1) Weighing talc, kaolin, and high plasticity clay according to the above-mentioned raw materials and formula and carrying out wet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com