A kind of preparation method and application of modified oyster shell powder

A technology of oyster shell powder and oyster shell, which is applied in the application, inorganic fertilizer, calcareous fertilizer and other directions, can solve the problems of occupying land resources, environmental pollution, etc., and achieves the effects of high material strength, reduced production cost, and attractive application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

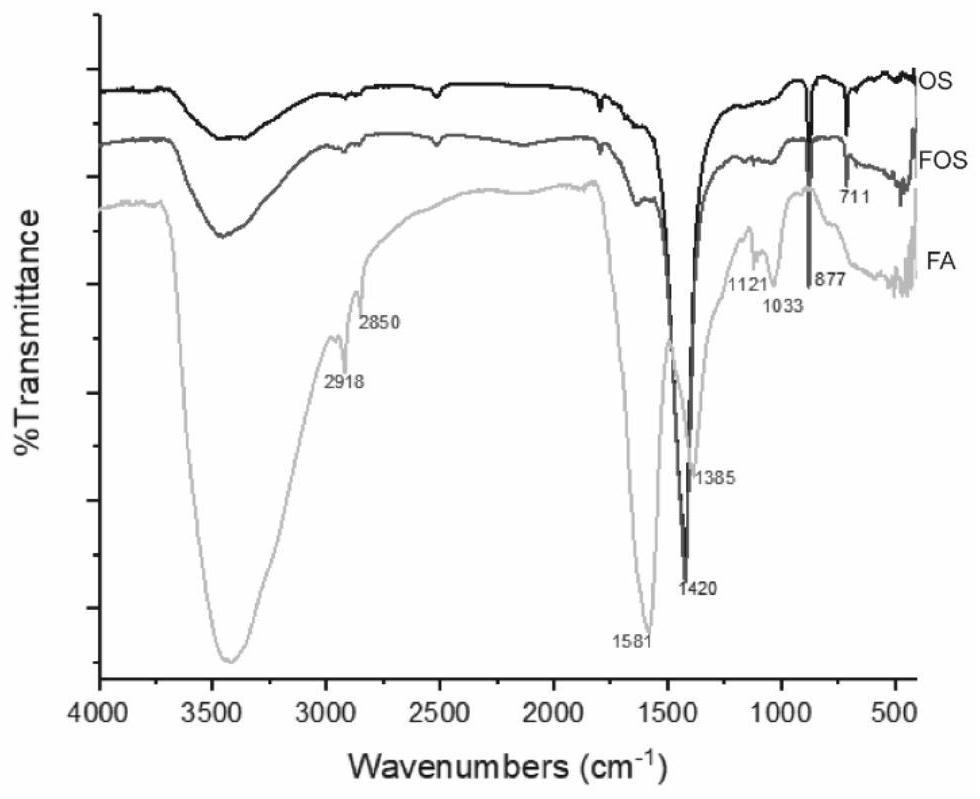

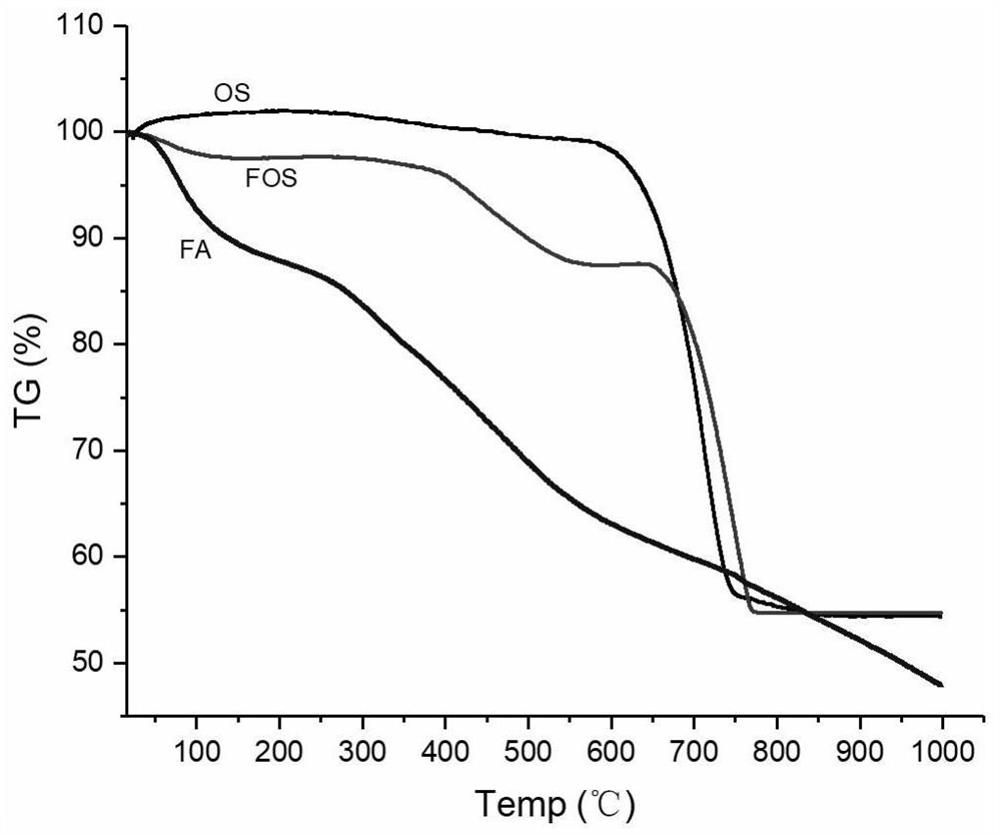

[0034] The solid-phase grafting method uses maleic anhydride as a graft monomer and dibenzoyl peroxide as an initiator to immobilize fulvic acid on the surface of oyster shells to obtain an immobilized fulvic acid material. The specific process is as follows:

[0035]Mix 30g of oyster shell powder and 6g of fulvic acid into a three-necked flask, and mechanically stir at 200rpm for 30min. Add 0.32g of dibenzoyl peroxide and 3g of maleic anhydride to 5g of dimethylformamide and stir to dissolve. This is the initiation system. Add the triggering system dropwise into the above-mentioned three-neck flask mixed with oyster shell powder and fulvic acid under nitrogen protection and stirring conditions, react in a water bath at 70°C for 3 hours, and condense at the same time. After the reaction, the obtained black solid was dried and extracted with deionized water for 24 hours, dried again, and ground to obtain immobilized fulvic acid.

[0036] The prepared immobilized fulvic acid wa...

Embodiment 2

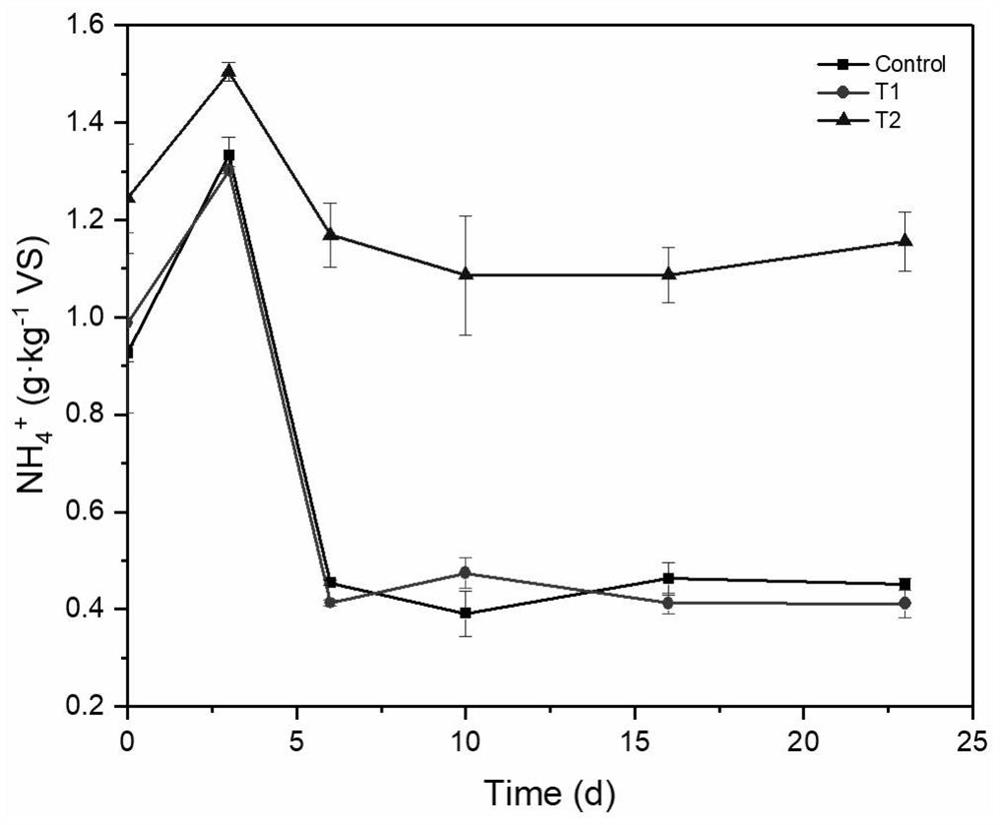

[0043] The modified oyster shell with immobilized fulvic acid in Example 1 was applied to the continuous high-temperature aerobic composting process of biogas residue. The addition amount was 0.42 times of the dry weight of the biogas residue, which was recorded as T2. The original oyster shell was used as the additive, and the addition amount was 0.42 times of the dry weight of the biogas residue, which was recorded as T1. No additive was used as the control group. The compost uses biogas residue as raw material, mixes it evenly with different additives, puts it in a 2.5L, 55°C constant temperature reactor, adjusts the initial water content to about 65%, and the ventilation rate is 0.1L / min / kg. The ammonia at the end of the reaction device The gas absorption unit was filled with 2% boric acid solution. The composting cycle is 23 days, and samples were taken on days 0, 3, 6, 10, 16, and 23 to measure the composting index according to the standard method in the literature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com