Production method of biological bacterium silicon fertilizer

A production method and technology of biological bacteria, applied in the field of silicon fertilizer production, can solve the problems of silicon waste, environmental pollution, etc., and achieve the effects of reducing harm, improving soil nutrient activity, and improving soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

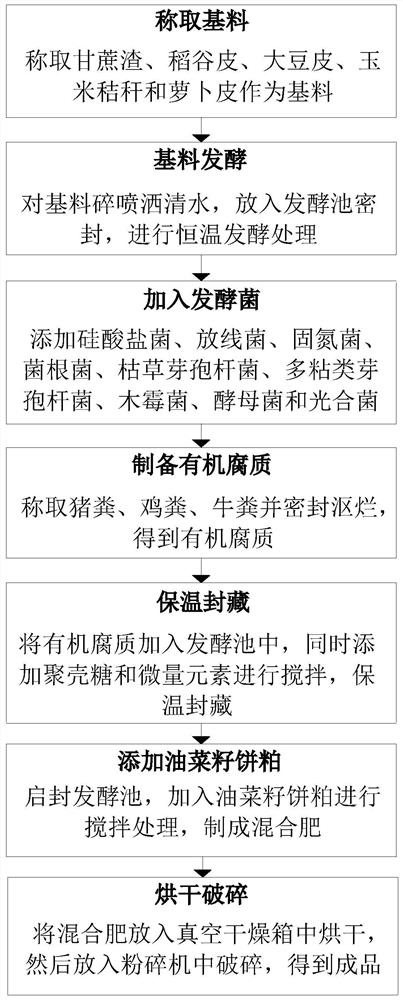

[0035] according to figure 1 Shown, present embodiment proposes a kind of production method of biological bacteria silicon fertilizer, comprises the following steps:

[0036] Step 1: Weigh the base material

[0037] Weigh according to the mass ratio: 20 parts of bagasse powder, 30 parts of rice hulls, 20 parts of soybean hulls, 40 parts of corn stalks and 10 parts of radish skins, as the base material, clean the base material, remove surface stains, dry and crush Processing, crushing particle size is to cross 50 mesh sieves, make base material broken and keep for subsequent use;

[0038] Step 2: base material fermentation

[0039] Put the crushed base material into the fermentation tank, then spray clean water into the fermentation tank to completely soak the base material, then seal the fermentation tank and carry out constant temperature fermentation treatment for 3 months. During constant temperature fermentation, the temperature is controlled at 33 degrees Celsius. Ever...

Embodiment 2

[0051] according to figure 1 Shown, present embodiment proposes a kind of production method of biological bacteria silicon fertilizer, comprises the following steps:

[0052] Step 1: Weigh the base material

[0053] Weigh according to the mass ratio: 30 parts of bagasse powder, 50 parts of rice hulls, 40 parts of soybean hulls, 60 parts of corn stalks and 20 parts of radish skins, as the base material, clean the base material, remove surface stains, dry and crush Processing, crushing particle size is to cross 50 mesh sieves, make base material broken and keep for subsequent use;

[0054] Step 2: base material fermentation

[0055] Put the crushed base material into the fermentation tank, then spray clean water into the fermentation tank to completely soak the base material, then seal the fermentation tank and carry out constant temperature fermentation treatment for 3 months. During constant temperature fermentation, the temperature is controlled at 33 degrees Celsius. Ever...

Embodiment 3

[0067] according to figure 1 Shown, present embodiment proposes a kind of production method of biological bacteria silicon fertilizer, comprises the following steps:

[0068] Step 1: Weigh the base material

[0069] Weigh according to the mass ratio: 60 parts of bagasse powder, 80 parts of rice hulls, 50 parts of soybean hulls, 90 parts of corn stalks and 30 parts of radish skins, as the base material, clean the base material, remove surface stains, dry and crush Processing, crushing particle size is to cross 50 mesh sieves, make base material broken and keep for subsequent use;

[0070] Step 2: base material fermentation

[0071] Put the crushed base material into the fermentation tank, then spray clean water into the fermentation tank to completely soak the base material, then seal the fermentation tank and carry out constant temperature fermentation treatment for 3 months. During constant temperature fermentation, the temperature is controlled at 33 degrees Celsius. Ever...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com