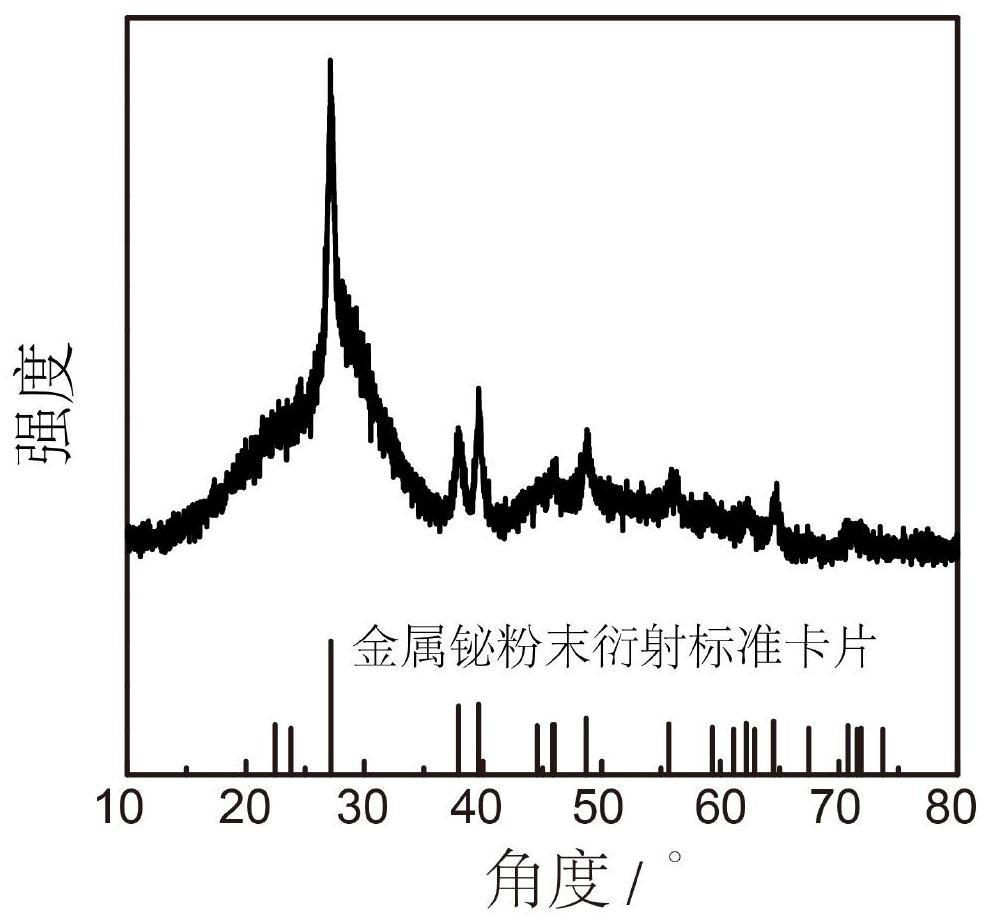

Metal bismuth nanoparticle composite material and preparation method and application thereof

A composite material, bismuth particle technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult to maintain catalytic stability, weak force, etc., to ensure long-term stability , Well-developed pores and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

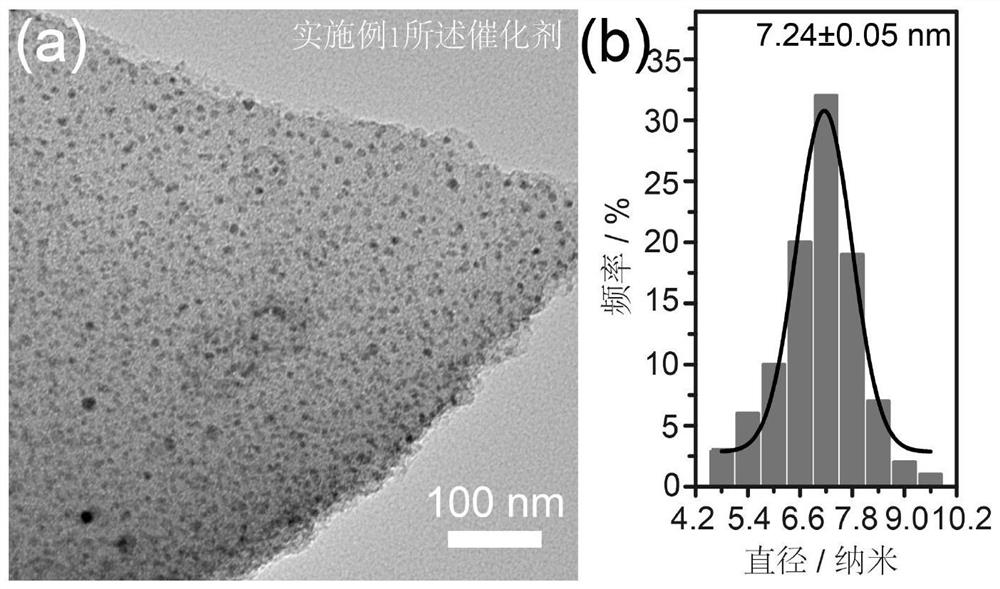

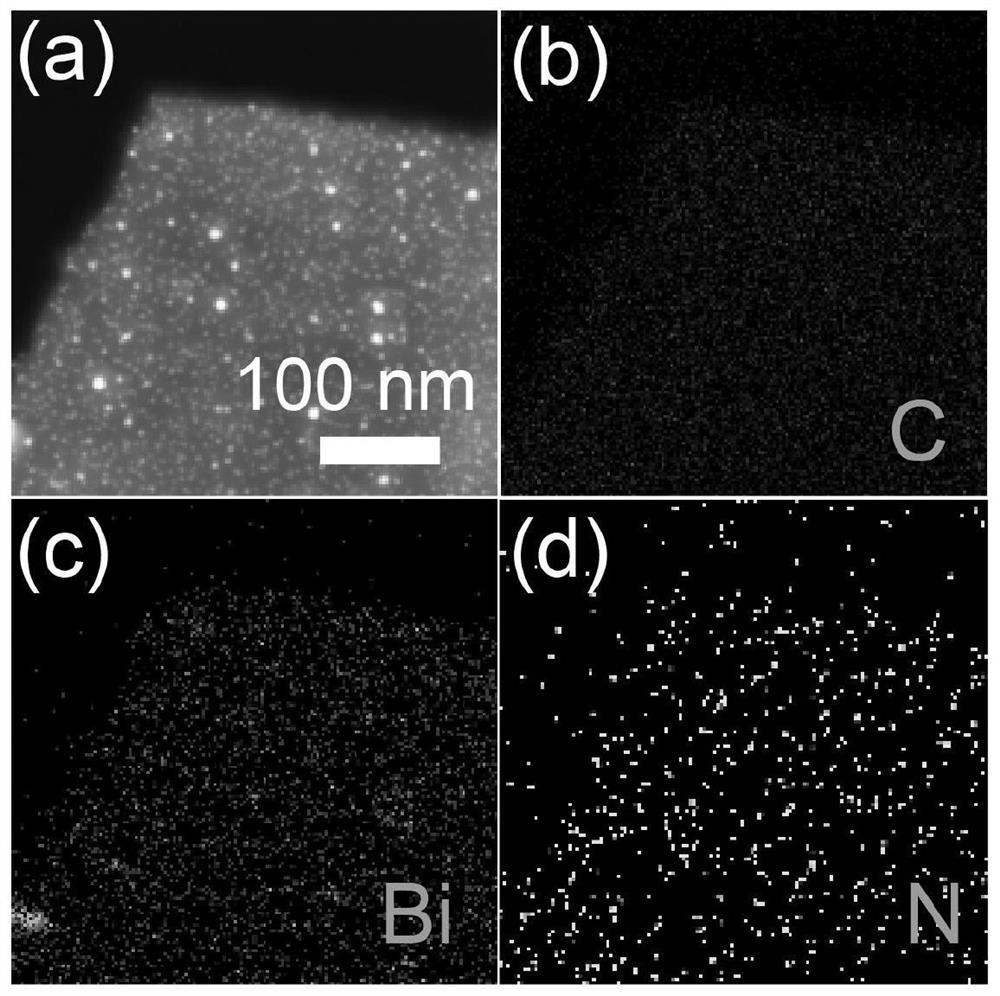

Embodiment 1

[0042] Dissolve 10 mg of tetraaminophenylporphyrin in 20 mL of chloroform and 20 mL of dimethylformamide mixed solvent, ultrasonic for 1 hour, then add Ketjen Black (model ECP-600JD, pore size approx. 10nm nanometer, the specific surface area is 1400m 2 / g) 60 mg, continue to sonicate for 1 hour, centrifuge to collect the solid product after impregnation and adsorption for 12 hours, wash with ethanol twice, and then vacuum-dry at 60°C for 6 hours. The dried samples were taken out and baked in a tube furnace with two temperature zones at 100°C for 1 hour. Take 60 mg of baked porous carbon and disperse it in 20 mL of dimethylformamide solution with 1 mmol of bismuth nitrate dissolved in it, ultrasonically for 1 hour and then soak for 12 hours, add 10 mL of dimethylformamide solution with 1 mmol of sodium borohydride dropwise into the above solution The formamide solution was stirred for 15 minutes at the same time, centrifuged and washed with ethanol for 3 times, and vacuum-dri...

Embodiment 2

[0054] Prepared according to the same method as in Example 1, the difference is that the tetraaminophenylporphyrin quality added in Example 1 is changed from 10 mg to 5 mg, and as a result, the size of the metal bismuth nanoparticles loaded on the porous carbon has no significant change, Then the composite catalyst obtained is tested in 0.5M potassium bicarbonate solution, and the current density is 43.5 mA / cm when the potential is -1.0 volts 2 , the faradaic efficiency of formic acid is 86.2%. Under the condition that the constant potential is -0.9 volts and the Faraday efficiency is maintained at least 80%, the stability test lasts for 15 hours.

Embodiment 3

[0056] Prepared according to the same method as in Example 1, the difference is that the quality of tetraaminophenylporphyrin added in Example 1 is changed from 10 mg to 15 mg, and as a result, the size of the metal bismuth nanoparticles loaded on the porous carbon has no significant change, Then the composite catalyst obtained is tested in 0.5M potassium bicarbonate solution, and the current density is 40.6 mA / cm when the potential is -1.0 volts 2 , the faradaic efficiency of formic acid is 88.4%. Under the condition that the constant potential is -0.9 volts and the Faraday efficiency is maintained at least 80%, the stability test lasts for 14 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com