CD-ROM-actuated artificial muscle material as well as preparation method and application thereof

An artificial muscle, optical drive technology, applied in rayon manufacturing, textile and papermaking, one-component synthetic polymer rayon, etc., can solve the problems of low sensitivity, bulky finished products, poor durability, etc., achieve less nodules, mechanical The effect of less loss and less structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

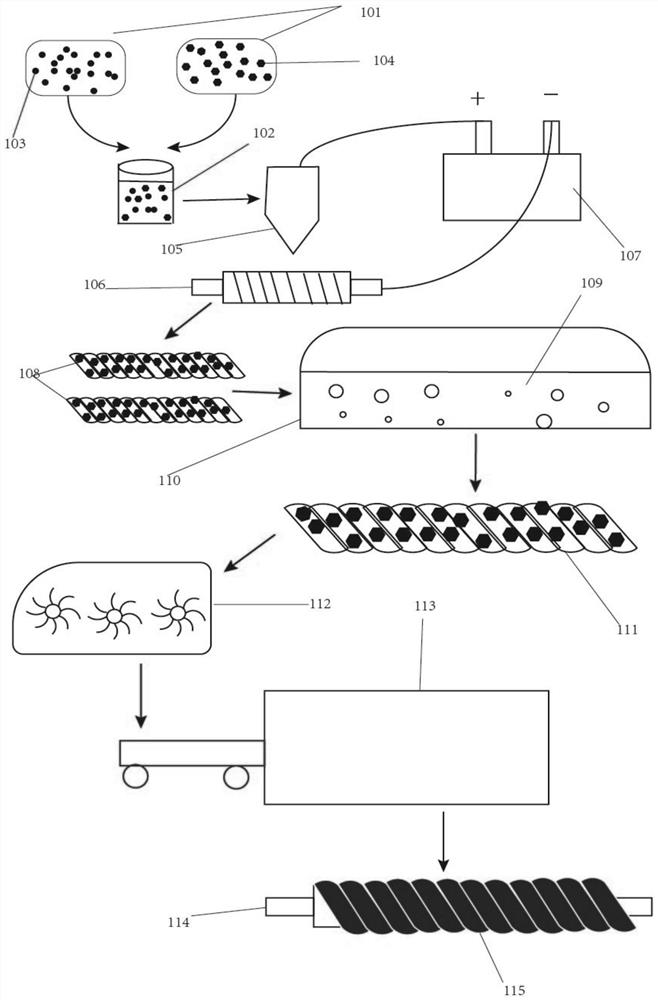

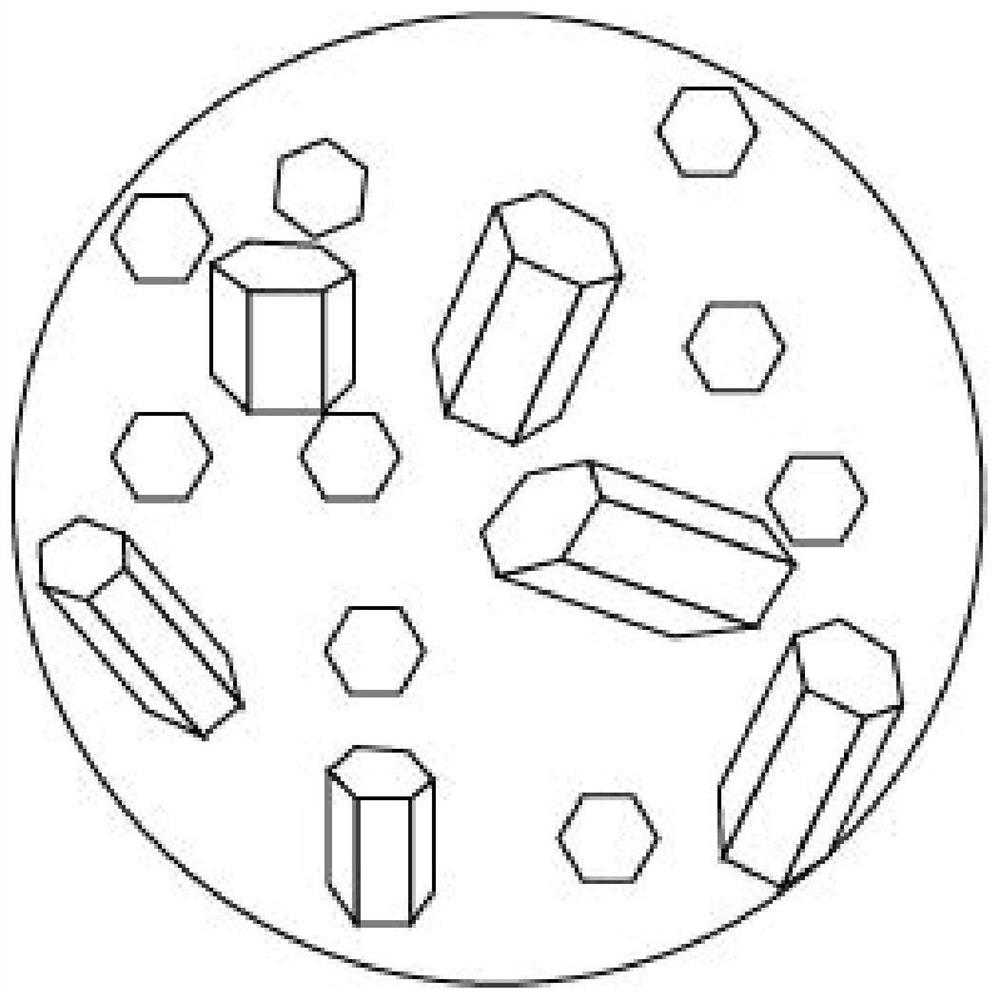

[0041] This example provides a preparation process of an optical drive actuated artificial muscle material and the structural system used, such as figure 1As shown, the vacuum drying device 101 comprising polyurethane slices and carbon nanotubes respectively arranged on both sides; N, N-dimethylformamide (DMF) and tetrahydrofuran ( THF) dissolving tank 102 of mixed solvent; Polyurethane slice 103; Carbon nanotube 104; Electrospinning needle 105; Fiber collecting device 106; Secondary twisting device 111; Low-temperature drying device 112; Heat setting device 113; Winding collection device 114; Finished artificial muscle material 115, wherein the distribution state of carbon nanotubes in the artificial muscle material made is as follows figure 2 shown. Before the material enters the dissolution tank 102 of N,N-dimethylformamide (DMF) and tetrahydrofuran (THF) mixed solvent selectively added with ultraviolet light absorber, the polyurethane chips 103 and carbon nanotubes 104 h...

Embodiment 2

[0043] This example provides a method for preparing an optical drive actuated artificial muscle material, the preparation method comprising the following steps:

[0044] (1) Select polyurethane slices and carbon nanotubes as raw materials, and dry them separately. The drying adopts vacuum drying, and the conditions of vacuum drying are: the air pressure is 19.5kPa, the temperature is 60°C, and the drying time is 24 hours;

[0045] (2) Disperse the dried polyurethane, carbon nanotubes, and ultraviolet absorber o-hydroxybenzophenone in a mixed solvent at 70° C. to make a mixed spinning solution; wherein, the mixed The solvent is composed of N,N-dimethylformamide and tetrahydrofuran, the feeding volume ratio of the N,N-dimethylformamide to the tetrahydrofuran is 1:1, the polyurethane, the carbon nanotubes and the The mass ratio of the ultraviolet absorber o-hydroxybenzophenone is 40: 4: 1;

[0046] The dispersion process adopts ultrasonic resonance, the duration of ultrasonic re...

Embodiment 3

[0059] This example provides a method for preparing an optical drive actuated artificial muscle material, the preparation method comprising the following steps:

[0060] (1) Select polyurethane slices and carbon nanotubes as raw materials, and dry them separately. The drying adopts vacuum drying, and the conditions of vacuum drying are: the air pressure is 19.5kPa, the temperature is 60°C, and the drying time is 24 hours;

[0061] (2) Disperse the dried polyurethane, carbon nanotubes, and ultraviolet absorber o-hydroxybenzophenone in a mixed solvent at 70° C. to make a mixed spinning solution; wherein, the mixed The solvent is composed of N,N-dimethylformamide and tetrahydrofuran, the feeding volume ratio of the N,N-dimethylformamide to the tetrahydrofuran is 1:1, the polyurethane, the carbon nanotubes and the The mass ratio of the ultraviolet absorber o-hydroxybenzophenone is 40: 4: 1;

[0062] The dispersion process adopts ultrasonic resonance, the duration of ultrasonic re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com