Printing process of polyester fabric

A printing process and fabric technology, which is applied in the field of textile processing, can solve the problems of low color fixation rate of disperse dyes and affect the aesthetics of polyester fabrics, etc., and achieve the effect of improving color fastness, reducing influence, and improving color fixation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

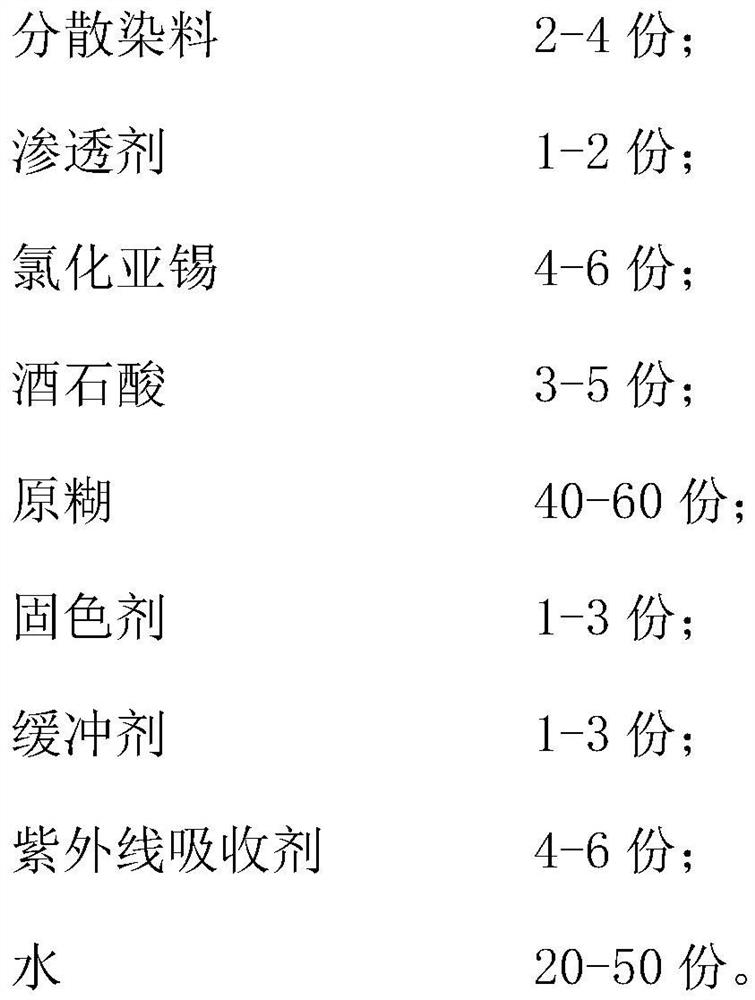

Method used

Image

Examples

preparation example 1

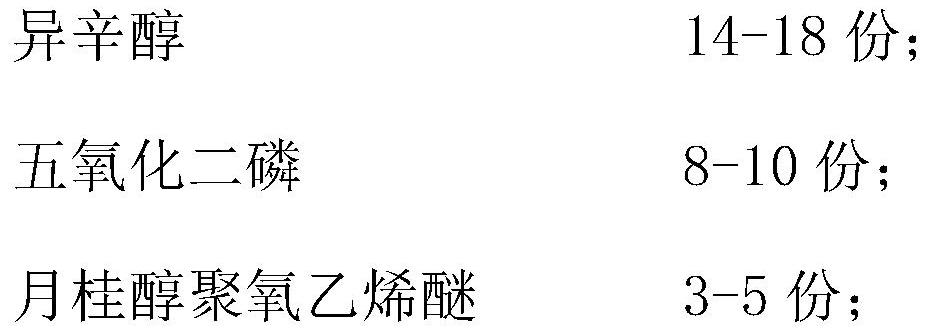

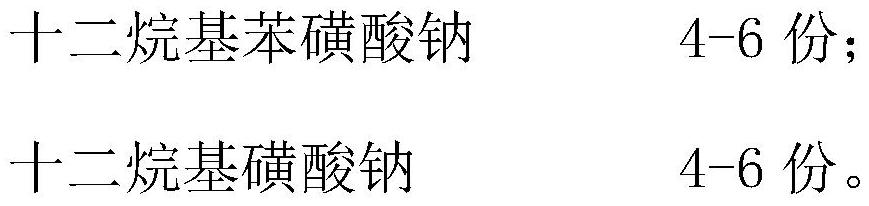

[0061] An penetrating agent, made of a weight of the following weight: 1.4 kg isooctanol; 0.8 kg of pentoxide; 0.3 kg of lauryl polyoxyethylene ether; 0.4 kg of sodium dodecyl benzene sulfonate; 0.4kg ten Sodium dialkyl sulfonate;

[0062] A preparation process of a penetrant includes the following process steps:

[0063] Step 1, the proportion of 1.4 kg is octoxide is added to the reaction kettle, and the reaction kettle is heated and stirred, and the temperature of the reactor is 40 ° C, control the stirring speed of 100R / min, and 0.8 kg of oxide The phosphorus was added to the reactor, and after the addition of pentoxide, the temperature of the reactor was controlled to 70 ° C, and the heating time was 2 h.

[0064] Step 2, cooling and filtration of the reaction kettle to obtain an isooctanol phosphate, a cooling reaction kettle temperature to 40 ° C or less, after disconnection, resulting in anhydrolysis isooctanol phosphate product.

[0065] Step 3, the hydrolyzate alkoxide...

preparation example 2-5

[0067] Preparation Example 2-5 The weight fraction of the material and the process parameters of the process parameters are meter 2, and the remaining balances are the same as those of the Preparation Example 1.

[0068] Table 2 Preparation Example 2-5 Welness Number and Process Parameters of Materials in Osmarers

[0069]

[0070]

preparation example 6

[0072] A solid color, made of raw materials of the following weight parts: 1.8 kg of tetraethylene pentamine; 5.5 kg of epoxy chloropropane; 1.5 kg of triethylamine; 8kg coating;

[0073] Where the coating is from NA 2 O · NSIO 2 Composition, where n = 2;

[0074] The preparation process of a fixing agent specifically includes the following process steps:

[0075] Step 1, in proportion to the 1.8 kg of tetraethylene pentamine into the reactor, the reactor is constantly heating, the system temperature in the reactor is 15 ° C, and 5.5 kg of epoxypropylene is added to the reactor in proportion. The mixture A was obtained, and the mixture A was stirred, and the stirring speed was 100 r / min, and 1.5 kg of triethylamine was added to the mixture A, the control reaction temperature was 60 ° C, the control reaction time was 5 h, resulting in product B, continuous The product B was heated and obtained by gum product B.

[0076] Step 2, press 8kgna 2 O · 2SIO 2 The dissolved and heating w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com