Preparation method and application of a lignin-based adsorption-catalytic material

A catalytic material and lignin-based technology, which is applied in the preparation of lignin-based adsorption-catalytic materials and the removal of chlorinated aromatics in gas and the removal of low-concentration chlorinated aromatics, which can solve the problems of poor single adsorption and single catalytic effect , to achieve low price, improve stability, and increase the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

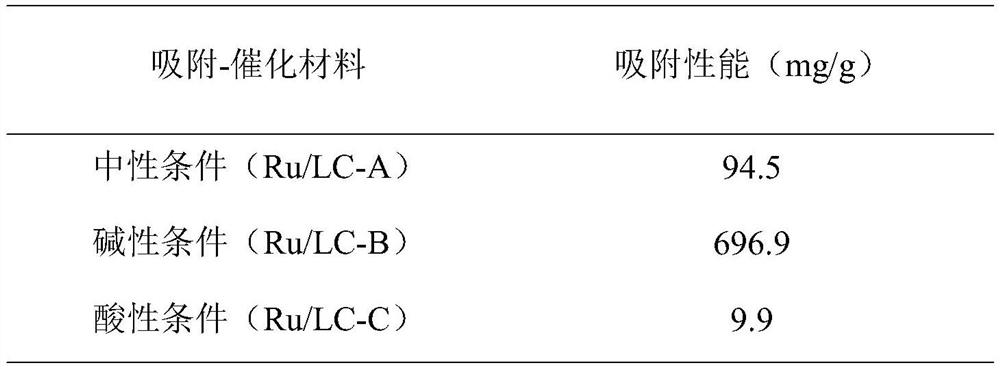

Examples

Embodiment 1

[0023] 1. Lignin pretreatment

[0024] Weigh 10 g of alkaline lignin, pass through a 60-mesh sieve, and obtain the under-sieve part and put it in a drying oven for 24 hours of drying treatment. Then take 5g of potassium hydroxide powder and dissolve it in deionized water to make an alkaline KOH solution with pH=11;

[0025] Mix 5 g of dried lignin with 25 mL of the above KOH solution, and stir at room temperature for 2 h.

[0026] Add a HCl solution with a concentration of 1mol / L to neutralize, then wash with deionized water until neutral, filter with suction, and place the obtained filter cake in an oven for drying at a drying temperature of 105°C and a drying time of 13 hours;

[0027] 2. Preparation of adsorption-catalytic materials

[0028] Prepared by an equal-volume impregnation method, slowly drop distilled water into 5 g of the above-mentioned pretreated lignin (LC-B) until the above-mentioned material absorbs water just to reach saturation, and the volume of the imp...

Embodiment 2

[0048] The steps of this embodiment are the same as those of Embodiment 1, except that the loading of Ru in this embodiment is 1 wt%.

Embodiment 3

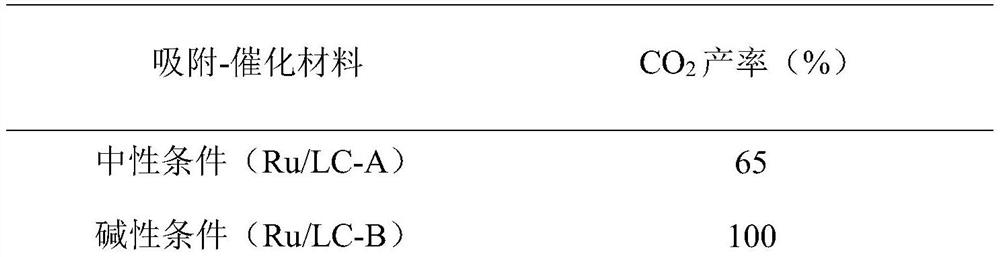

[0062] In this example, the adsorption-catalytic material (Ru / LC-B) prepared in Example 1 was used to treat chlorinated aromatic hydrocarbons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com