Agricultural microbial enzyme, bio-organic fertilizer and preparation method

A bio-organic fertilizer and microbial technology, which is applied in the field of bio-organic fertilizer and its preparation, and agricultural microbial enzymes, can solve the problems of high price, limitation, and unstable effect, and achieve the effect of stable effect, long shelf life, and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

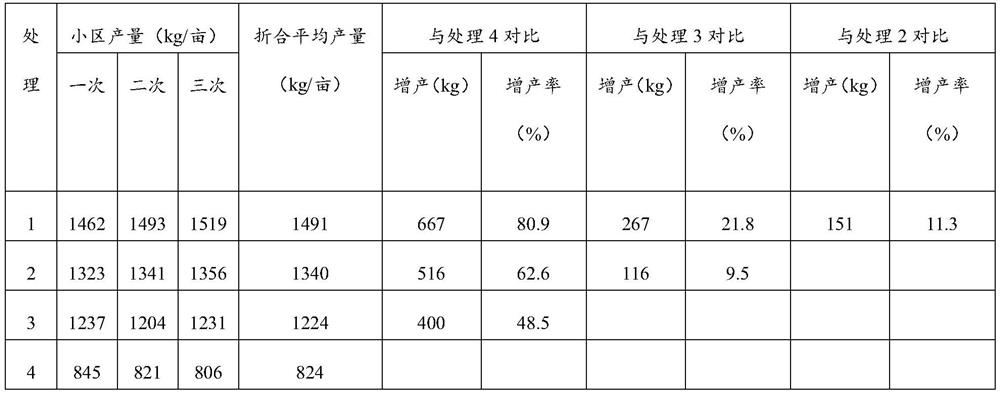

Examples

preparation example Construction

[0037] Further preferably, the preparation method of the agricultural microbial enzyme of the present invention comprises the following steps: mixing and stirring corn flour, wheat bran, rice husk, and water evenly, after sterilization, inoculating the microbial agent, and fermenting to obtain the agricultural microbial enzyme. More preferably, the sterilization temperature is 120°C-130°C for 0.5-1 hour, and the fermentation temperature is 24-26°C for 1-2 weeks. The present invention has no special limitation on the sterilization and fermentation methods, and conventional sterilization and fermentation methods in the field can be adopted.

[0038] As an alternative, the preparation method of the agricultural microbial enzyme is as follows: mix corn flour, wheat bran, rice husk, and water, put them into a bacteria bag and tie the mouth, put the fed bacteria bag into a sterilization pot at high temperature Sterilize, take it out and wait for natural cooling, inoculate the microb...

Embodiment 1

[0047] An agricultural microbial enzyme, consisting of the following raw materials in parts by weight: 30 parts of corn flour, 30 parts of wheat bran, 30 parts of rice husk, 0.1 part of microbial agent, and 30 parts of water; the effective number of viable bacteria of the microbial agent is not low Bacillus subtilis 100 billion / g, Bacillus licheniformis 100 billion / g, Bacillus amyloliquefaciens 100 billion / g, Bacillus megaterium 10 billion / g, Bacillus jelly 10 billion / g, Bacillus lateralis 10 billion / g gram, Aspergillus niger 10 billion / gram, yeast 10 billion / gram, lactic acid bacteria 100 billion / gram, actinomycetes 100 billion / gram.

[0048] The preparation method is as follows: mix corn flour, wheat bran, rice husk, and water, put them into a bacteria bag and tie the mouth, put the fed bacteria bag into a sterilizer for high-temperature sterilization for 45 minutes, take it out and let it cool naturally, and inoculate the microorganisms For the bacterial agent, the inoculat...

Embodiment 2

[0050] An agricultural microbial enzyme, consisting of the following raw materials in parts by weight: 10 parts of corn flour, 10 parts of wheat bran, 10 parts of rice husk, 0.01 part of microbial agent, and 20 parts of water; the effective number of viable bacteria of the microbial agent is not low Bacillus subtilis 100 billion / g, Bacillus licheniformis 100 billion / g, Bacillus amyloliquefaciens 100 billion / g, Bacillus megaterium 10 billion / g, Bacillus jelly 10 billion / g, Bacillus lateralis 10 billion / g gram, Aspergillus niger 10 billion / gram, yeast 10 billion / gram, lactic acid bacteria 100 billion / gram, actinomycetes 100 billion / gram.

[0051] The preparation method is as follows: mix corn flour, wheat bran, rice husk, and water, put them into a bacteria bag and tie the mouth, put the fed bacteria bag into a sterilization pot for high-temperature sterilization for 0.5 hours, take it out, let it cool naturally, and inoculate For the microbial agent, the inoculated bacteria bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com