Electropolarized particle, preparation method thereof, and application of electropolarized particle to electropolarized color-changing optical film

An electric polarization, optical film technology, applied in the direction of color-changing fluorescent materials, cyanide reaction preparation, chemical instruments and methods, etc., to achieve the effects of easy large-scale preparation, good stability, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

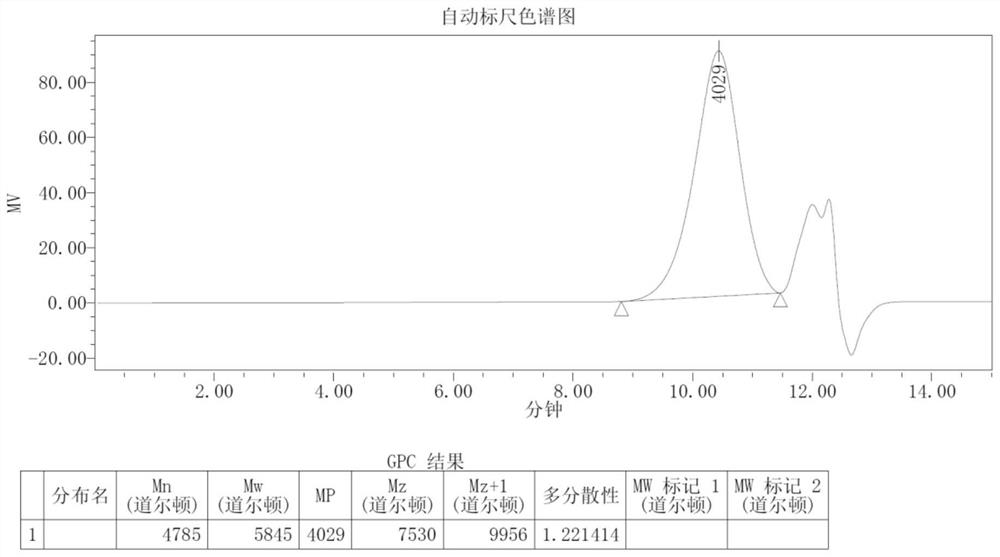

[0057] The preparation method of polyisooctyl methacrylate: 19.8g isooctyl methacrylate (purchased from Hubei Jusheng Technology Co., Ltd.) and 100mL ethyl acetate were added to a 250mL three-necked bottle, and nitrogen gas was introduced for 15 minutes to remove the air. Add 2.6mL of 1-octylthiol, raise the temperature rapidly to 65°C, slowly add 246mg / 30mL of azobisisobutyronitrile (AIBN) in ethyl acetate, and stop the reaction after 10h of reaction. After extraction, washing, rotary evaporation, and vacuum distillation to remove low-boiling fractions, polyisooctyl methacrylate is obtained. Use rotational viscometer to test its viscosity to be 4700cps. The molecular weight and distribution diagram of polyisooctyl methacrylate are as follows image 3 shown.

[0058] The preparation method of polydecyl methacrylate: add 22.6g of decyl methacrylate (purchased from Hubei Jinleda Chemical Co., Ltd.) and 100mL of ethyl acetate into a 250mL three-necked bottle, pass through nitro...

Embodiment 1

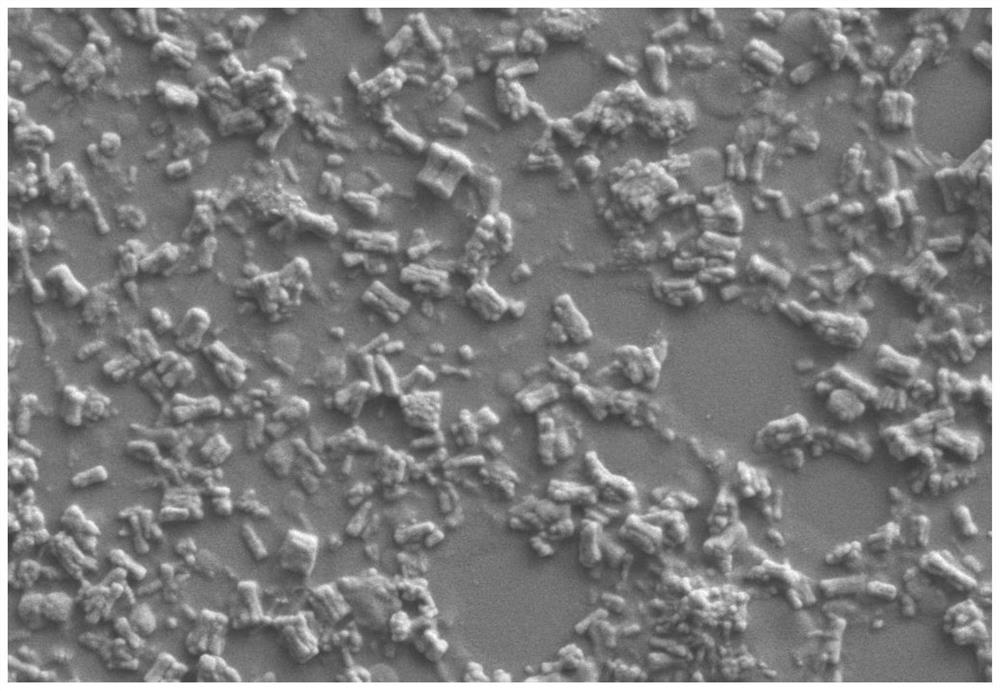

[0062] 1) Add 1.8g of ethyl cellulose and 50mL of ethyl acetate to a 100mL three-necked flask in sequence, and stir thoroughly to completely dissolve the ethyl cellulose in the ethyl acetate. The reaction temperature was raised to 60°C, and then 3.8g of iodine element, 2.92g of ethylenediaminetetraacetic acid (the structural formula is shown below, purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.), 1.9g of anhydrous copper iodide, 4mL of methanol and 0.1g of deionized water, and stop the reaction after reacting at 60°C for 16h. The obtained product was centrifuged at 12000r for 60min, and the upper liquid was poured off. And use ethyl acetate to wash the solid at the bottom of the centrifuge bottle into a glass bottle, ultrasonically disperse, and then continue the centrifugation. The above operations of centrifugation and washing were repeated 3 times. Finally, the precipitate was washed and dispersed in ethyl acetate to obtain a dispersion of electrically p...

Embodiment 2

[0067] 1) Add 1.62g of cellulose acetate and 60mL of ethyl acetate to a 100mL three-necked flask in sequence, and stir thoroughly to completely dissolve the cellulose acetate in the ethyl acetate. Raise the reaction temperature to 65°C, then add 2.54g iodine element, 1.9g nitrilotriacetic acid (the structural formula is as follows, purchased from Nanjing Bangnuo Biotechnology Co., Ltd.), 1.9g anhydrous copper iodide, 5mL ethanol and 0.2 g deionized water. And stop the reaction after reacting at 65°C for 12h. The obtained product was centrifuged at 12000 r for 40 min, and the upper liquid was poured off. And use ethyl acetate to wash the solid at the bottom of the centrifuge bottle into a glass bottle, ultrasonically disperse, and then continue the centrifugation. The above operations of centrifugation and washing were repeated 3 times. Finally, the precipitate was washed and ultrasonically dispersed into ethyl acetate to obtain a dispersion of electrically polarized particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com