Copper-based composite material, preparation method and application of copper-based composite material in field of photothermal conversion

A copper-based composite material and photothermal technology, which is applied in the components of solar collectors, solar thermal energy, solar thermal power generation, etc., can solve problems such as the difficulty of making breakthroughs and the photothermal conversion performance of a single photothermal material , to achieve the effect that the reaction process is easy to control, the preparation method is simple and convenient, and the yield is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

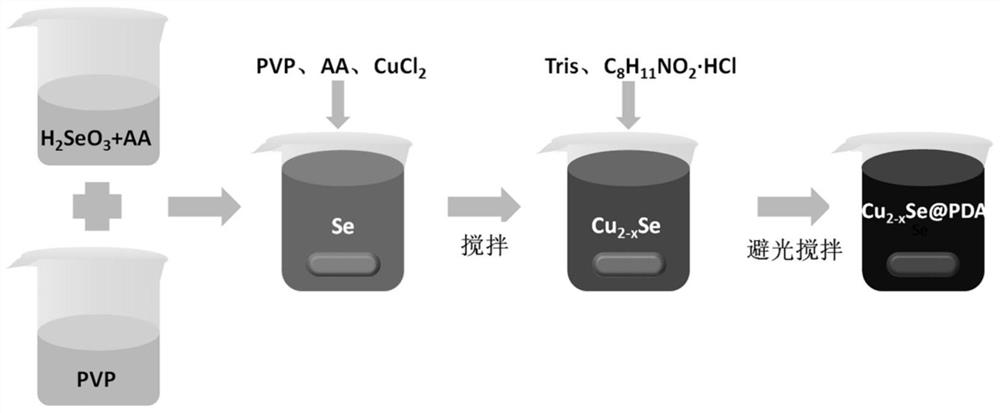

[0067] The present invention also provides a preparation method for the above-mentioned copper-based composite material, comprising the following steps:

[0068] Step (1): Preparation of nano-selenium spheres

[0069] A certain amount of selenium source and the second catalyst are dissolved in deionized water successively, which is recorded as solution 1. (i.e. the first solution);

[0070] Another certain amount of polyvinylpyrrolidone (PVP) was dissolved in deionized water, and recorded as solution ② (i.e. the second solution);

[0071] Add the solution ① to the solution ② gradually for reaction, and keep stirring at a speed below 800r / min for 10-40min (stirring is to make the reaction product more uniform, preferably the stirring speed is 400-800r / min, such as 400r / min , 500r / min, 600r / min, 700r / min, 800r / min), the reaction is carried out at room temperature (25°C), and after the reaction is completed, the product nano-selenium spheres obtained by washing and centrifuging ...

Embodiment 1

[0097] The copper-based composite material of the polydopamine modified copper selenide nano-ellipsoid of the present embodiment, the preparation method is specifically as follows:

[0098] (1) Preparation of nano-selenium spheres

[0099] 20 mg of selenous acid (H 2 SeO 3 ) and 180mg of ascorbic acid (AA) were successively dissolved in 5mL deionized water, which was recorded as solution ①;

[0100] Another 40 mg of polyvinylpyrrolidone (PVP) was dissolved in 5 mL of deionized water, and recorded as solution ②;

[0101] Add the solution ① gradually to the solution ②, and keep stirring for 10 minutes. The reaction is carried out at room temperature (25°C). 6min;

[0102] (2) Preparation of copper selenide nano-ellipsoid

[0103] Add the selenium bulb solution, polyvinylpyrrolidone solution, copper chloride solution, and ascorbic acid solution into the reaction vessel in sequence at a volume ratio of 1:1:1:1 to obtain a mixed solution with a volume of 4mL, and keep stirring...

Embodiment 2

[0123] The copper-based composite material of the polydopamine modified copper selenide nano-ellipsoid of the present embodiment, the preparation method is specifically as follows:

[0124] (1) Preparation of nano-selenium spheres

[0125] 30 mg of selenous acid (H 2 SeO 3 ) and 200mg of ascorbic acid (AA) were successively dissolved in 10mL deionized water, which was recorded as solution ①;

[0126] Another 50 mg of polyvinylpyrrolidone (PVP) was dissolved in 10 mL of deionized water, and recorded as solution ②;

[0127] Add the solution ① gradually to the solution ②, and keep stirring for 10 minutes. The reaction is carried out at room temperature (25°C). 6min;

[0128] (2) Preparation of copper selenide nano-ellipsoid

[0129] Add the selenium bulb solution, polyvinyl alcohol solution, copper acetate solution, and hydrazine solution into the reaction vessel in sequence at a volume ratio of 2:3:2:4 to obtain a mixed solution with a volume of 11mL, and keep stirring for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com