Antibacterial polyester material and preparation method and application thereof

A polyester material and reaction technology, applied in the field of functional polymer material synthesis, can solve problems such as hindering the function of antibacterial functional groups, destroying harmful bacteria, weakening antibacterial performance, etc., to meet the requirements of environmental friendliness, great development potential, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

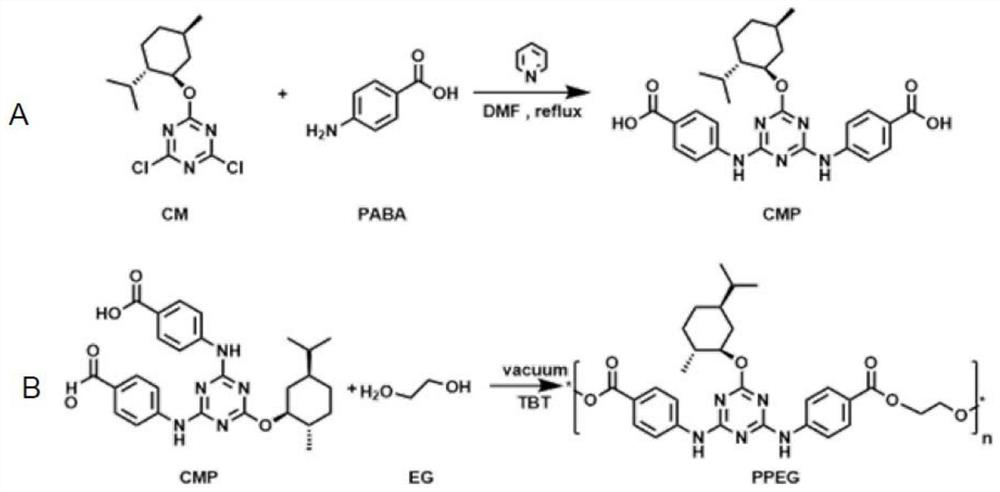

[0059] The preparation method of the antibacterial polyester material related to the second aspect of the present invention as described in the first aspect of the present invention includes the step of preparing antibacterial polyester material: under nitrogen atmosphere, dibasic alcohol compound, cyanuric chloride derivative The polymerized diacid monomer compound is uniformly mixed with the second catalyst, and undergoes melt polycondensation reaction to obtain a crude product of antibacterial polyester material.

[0060] In the present invention, the molecular structure of the polymerizable diacid monomer compound derived from cyanuric chloride is shown in formula (II):

[0061]

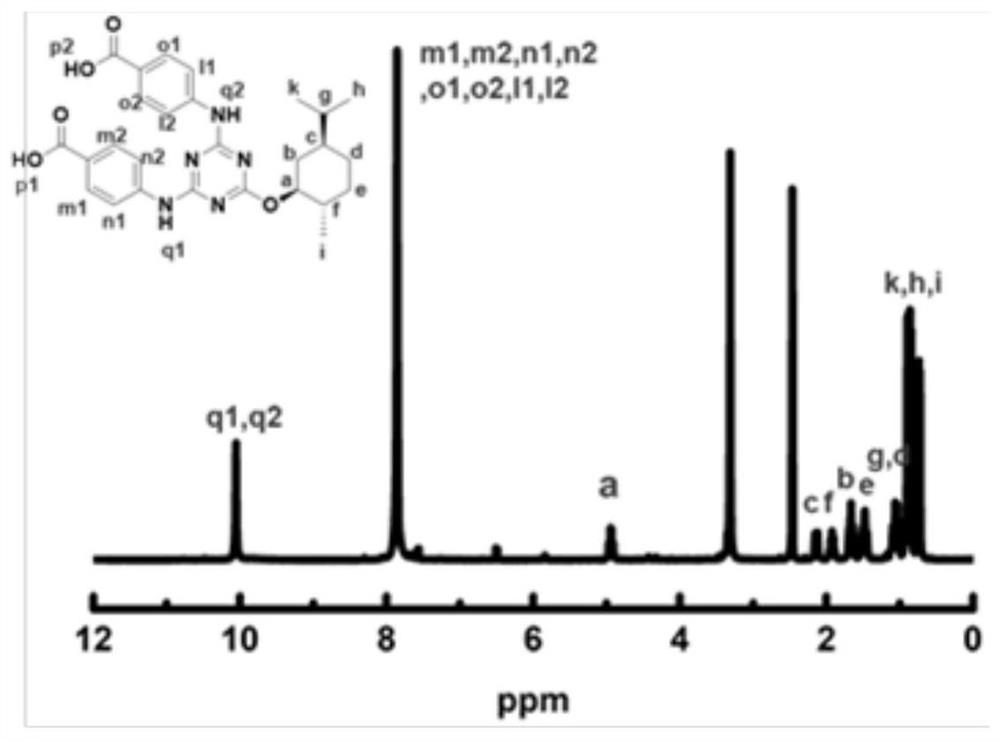

[0062] In the present invention, the reaction formula of the above-mentioned polymerizable diacid monomer compound derived from cyanuric chloride is as follows figure 1 Shown in Reaction Formula A, in some specific embodiments of the present invention, for example, the polymerizable diacid mon...

Embodiment 1

[0101] The preparation method of the antibacterial and anti-adhesion polymer material of the present embodiment is carried out as follows:

[0102] According to the molar ratio of 4:1 (304mg:548mg), p-aminobenzoic acid and menthol monosubstituted cyanuric chloride derivatives were dissolved in 20mL DMF (N,N-dimethylformamide) respectively, and dissolved in di The cyanuric chloride derivative of methyl formamide was constant-pressure titrated to the bis-aminobenzoic acid containing the first catalyst pyridine (3.95mg, the molar ratio of the cyanuric chloride derivative and the first catalyst pyridine was 1:0.05). In methylformamide, the temperature was raised to 140°C, and the mixture was refluxed for 3 hours to obtain a reaction mixture. The mixed solution is acidified and settled with an acidic ethanol-water mixture (pH=3), and the white solid obtained by drying the solid is a pure product of a polymerizable diacid monomer compound derived from cyanuric chloride (referred to ...

Embodiment 2

[0118] Para-aminobenzoic acid and menthol monosubstituted derivatives were dissolved in 20 mL of DMF (N,N-dimethylformamide) according to the molar ratio of 3:1 (411 mg: 304 mg), and dissolved in DMF using a constant pressure titration funnel. The menthol monosubstituted derivative was dropped into the p-aminobenzoic acid DMF solution containing pyridine (4.74mg, the molar ratio of the cyanuric chloride derivative and the first catalyst pyridine was 1:0.06), and the temperature was raised to 120 ° C and refluxed. 12h, the reaction mixture was obtained. The reaction mixture was settled with an acidic ethanol-water mixture (pH=3). Suction filtration, taking the filter cake and drying to obtain a white solid which is a diacid monomer compound with a yield of 60%.

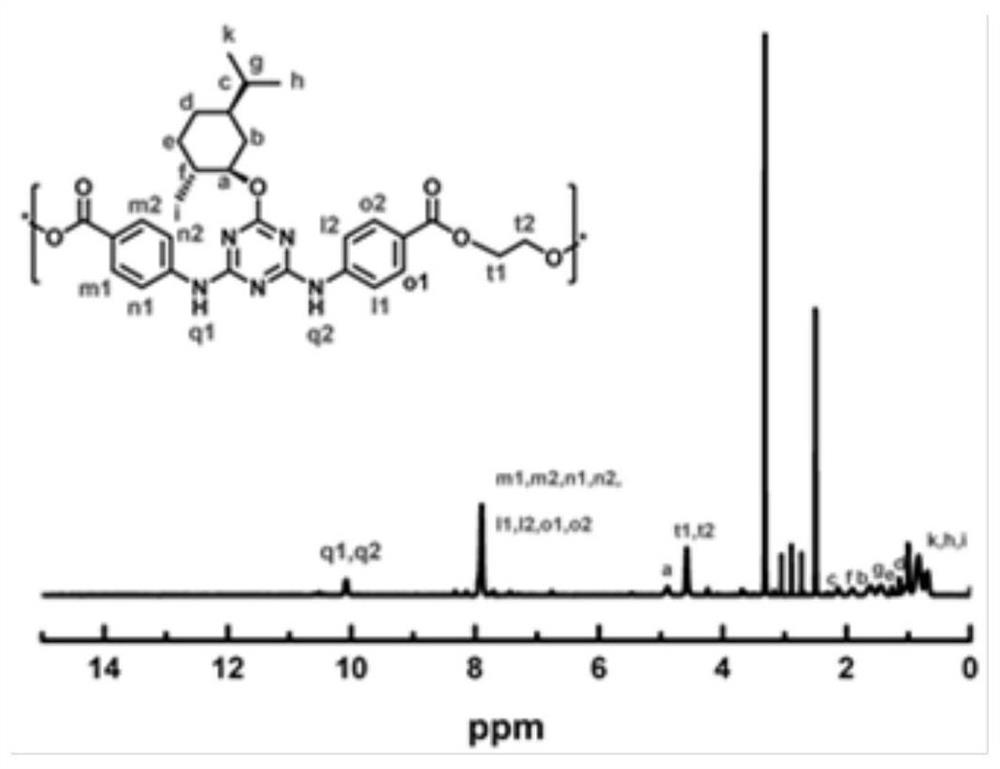

[0119] The diacid monomer compound and the diol compound were added in a three-necked flask equipped with an electric mixer according to the molar ratio of 1:1 (505mg:62mg), and 1% (5.05mg) of tetrabutyl titanate of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com