Method for preparing dextro-trans-DE chrysanthemic acid through enzymolysis

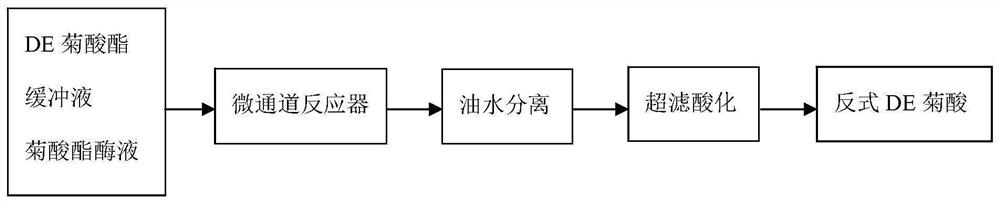

A technology for enzymatic hydrolysis and chrysanthemic acid, which is applied in the fields of organic chemistry, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems such as the preparation process of dextro-trans DE chrysanthemic acid that has not been found in research, and achieve stable control. , The effect of shortening the enzymatic hydrolysis reaction time and the small size of the production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Microchannel reactor: PDMS microchannel chip, the channel diameter is 300 μm, the length is 1000 mm, and the heat exchange medium is heat transfer oil.

[0034] (2) Preparation of D-trans DE chrysanthemic acid:

[0035] Microchannel reactor preparation: Control the residence time of the reaction system in each module by adjusting the flow rate of the delivery pump and the length of the microchannel. The residence time in the mixing module is 30 seconds, and the residence time in the reaction module is 60 seconds. The reaction is controlled by the external heat transfer oil system The temperature of each module of the device, the temperature of the mixing module is 35°C, and the temperature of the reaction module is 35°C.

[0036] EYN045 esterase 0.1g is dissolved in 10g water to obtain 10.1g esterase liquid, 2% ammonia water 100g, chrysanthemum acid ethyl ester (cis / trans=10 / 90) 10g, above-mentioned raw material adopts high-pressure metering pump in proportion respe...

Embodiment 2

[0038] (1) Microchannel reactor: stainless steel microchannel chip, channel diameter 500μm, length 1000mm, heat transfer medium is heat transfer oil.

[0039] (2) Preparation of D-trans DE chrysanthemic acid:

[0040] Microchannel reactor preparation: Control the residence time of the reaction system in each module by adjusting the flow rate of the delivery pump and the length of the microchannel. The residence time in the mixing module is 30 seconds, and the residence time in the reaction module is 80 seconds. The reaction is controlled by the external heat transfer oil system The temperature of each module of the device, the temperature of the mixing module is 40°C, and the temperature of the reaction module is 40°C.

[0041] EYN045 esterase 0.2g is dissolved in 20g water to obtain 20.2g esterase liquid, 2% ammonia water 200g, chrysanthemum acid ethyl ester (cis / trans=10 / 90) 20g, above-mentioned raw material adopts high-pressure metering pump respectively in proportion, at 0...

Embodiment 3

[0043] (1) Microchannel reactor: stainless steel microchannel chip, channel diameter 300μm, length 1000mm, heat transfer medium is heat transfer oil.

[0044] (2) Preparation of D-trans DE chrysanthemic acid:

[0045] Microchannel reactor preparation: Control the residence time of the reaction system in each module by adjusting the flow rate of the delivery pump and the length of the microchannel. The residence time in the mixing module is 30 seconds, and the residence time in the reaction module is 60 seconds. The reaction is controlled by the external heat transfer oil system The temperature of each module of the device, the temperature of the mixing module is 40°C, and the temperature of the reaction module is 40°C.

[0046] EYN045 esterase 0.1g is dissolved in 10g water to obtain 10.1g esterase liquid, 2% ammonia water 100g, chrysanthemum acid ethyl ester (cis / trans=10 / 90) 10g, above-mentioned raw material adopts high-pressure metering pump in proportion respectively, at 0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Channel diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com