Etching method of inclined through hole

A technology of hole wall and bottom surface, which is applied in the field of etching of inclined through holes to achieve the effect of easy metal filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

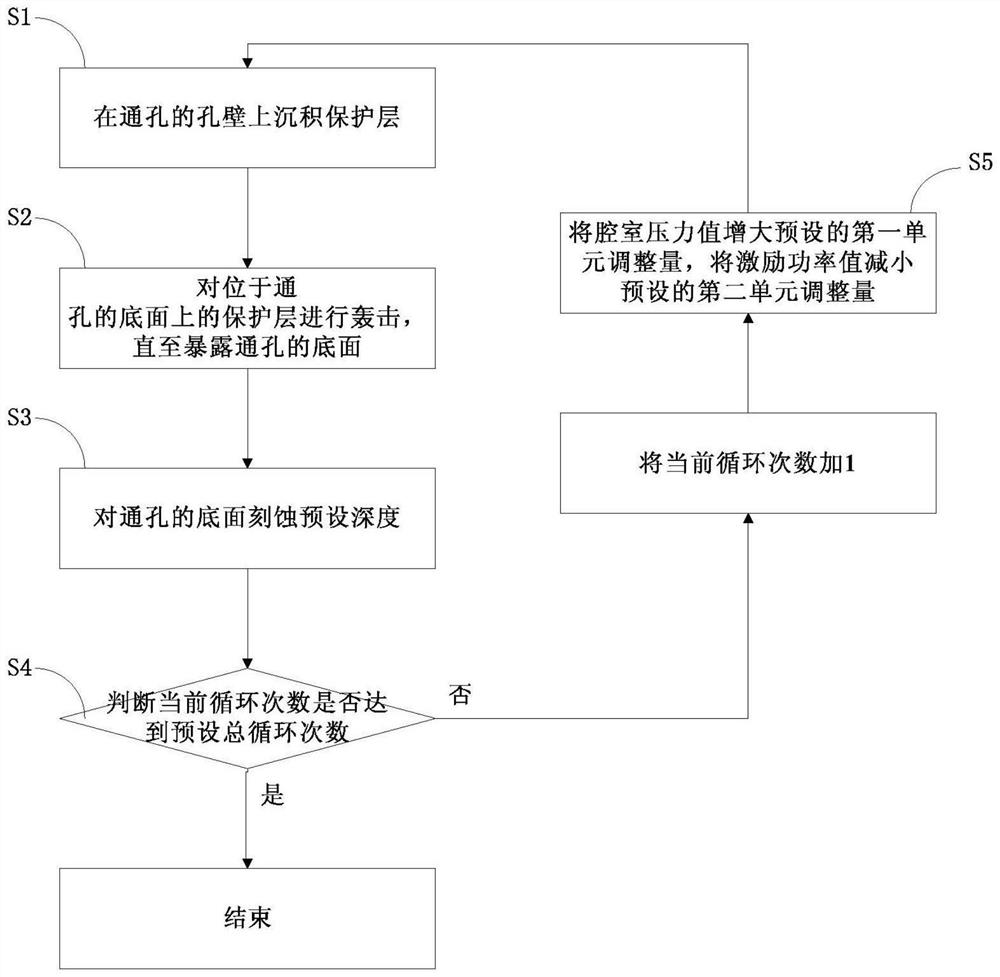

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides an etching method for inclined through holes, which is used to etch through holes with inclined walls on a film layer made of a wide bandgap semiconductor material, the wide bandgap semiconductor material includes silicon carbide or nitrogen Gallium chloride, these two materials are representative of the third generation of semiconductor materials. However, this embodiment is not limited thereto, and the above etching method can also be used to etch holes on the surface of a film layer made of third-generation semiconductor materials such as zinc oxide or diamond.

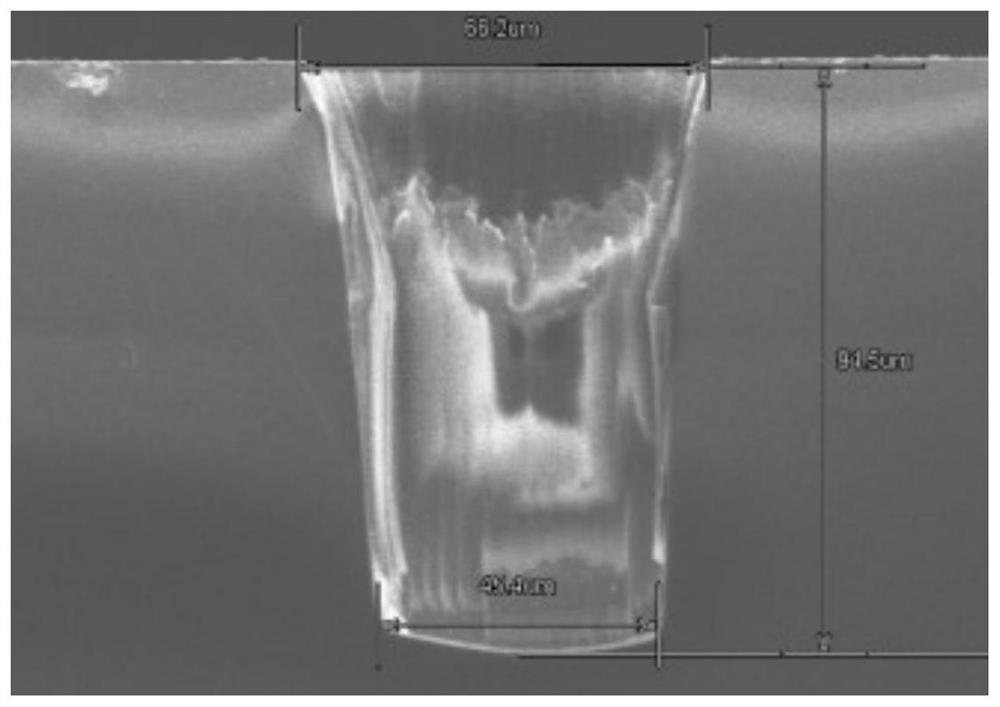

[0043] The above-mentioned wide-bandgap semiconductor materials generally have the characteristics of high hardness, high brittleness, and high melting point. This characteristic makes it difficult to process holes with inclined angles in the wide-bandgap semiconductor material film layer. The current etching method only A straight hole or a hole with a very small inclination angle o...

Embodiment 2

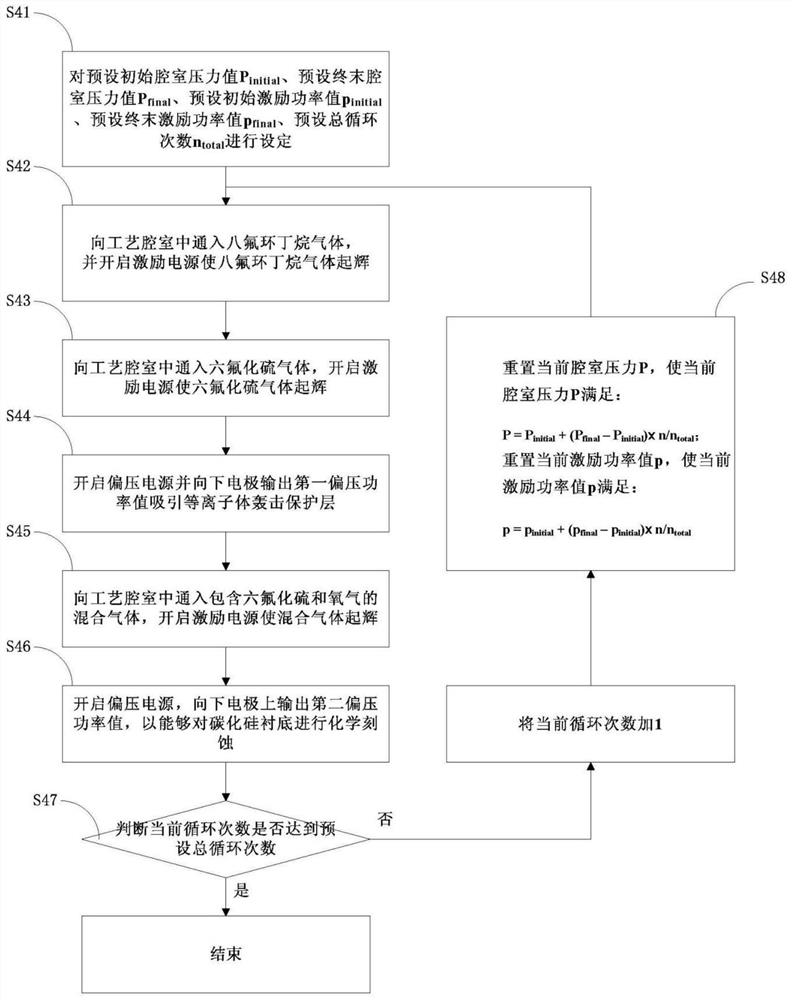

[0087] On the basis of Embodiment 1, this embodiment provides an etching method applied to an inclined through hole of a silicon carbide film layer, which specifically includes:

[0088] S41. For the preset initial chamber pressure value P initial , preset final chamber pressure value P final , preset initial excitation power value p initial , preset terminal excitation power value p final , preset total number of cycles n total make settings;

[0089] S42. Introduce octafluorocyclobutane gas into the process chamber, and turn on the excitation power to excite octafluorocyclobutane gas to form plasma. The plasma contains carbon ions and fluorine ions. Polymerization reaction can take place and generate fluorocarbon polymer, so that the fluorocarbon polymer is deposited on the surface of the film layer to form a protective layer;

[0090]Specifically, when performing the above step S42, the octafluorocyclobutane gas is simultaneously fed into the central air inlet and the ...

Embodiment 3

[0112] On the basis of Embodiment 1, this embodiment provides a method for etching through holes applied to gallium nitride film layers, such as Figure 4 As shown, it specifically includes:

[0113] S51. For the preset initial chamber pressure value P initial , preset final chamber pressure value P final , preset initial excitation power value p initial , preset terminal excitation power value p final , preset total number of cycles n total make settings;

[0114] S52. Introduce boron trichloride gas into the process chamber, turn on the excitation power to excite boron trichloride gas to form plasma, the plasma contains boron ions and chloride ions, wherein boron ions are catalyzed by high temperature and high pressure It will have a replacement reaction with the gallium nitride film layer, and generate a dense gallium boride compound on the gallium nitride film layer, so that the gallium boride compound can be deposited on the surface of the film layer to form a protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com