Multi-technology integrated separation process for producing high-purity helium from liquefied tail gas of helium-rich natural gas

A technology for natural gas and helium gas, applied in the field of multi-technology integrated separation process, can solve the problems of high purification of difficult helium gas, high adsorption difficulty, low solubility, etc., and achieve the effect of improving recovery rate and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

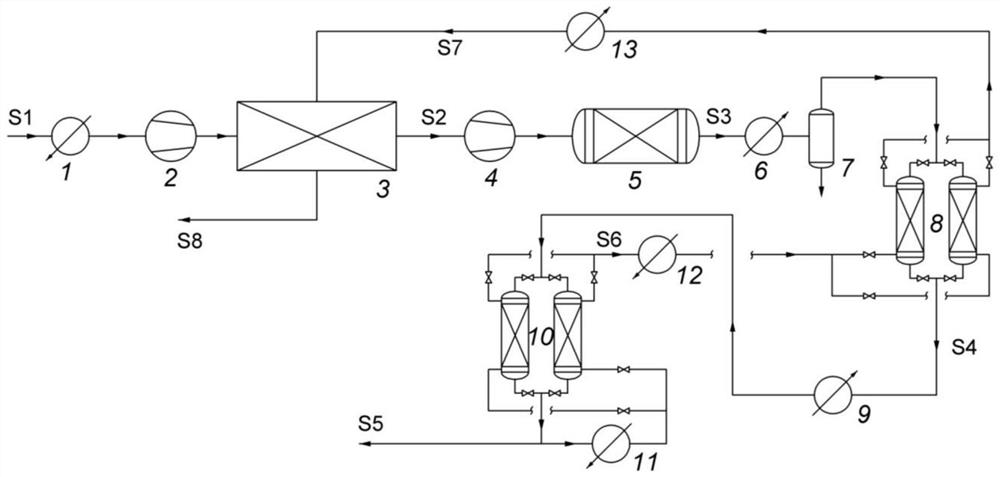

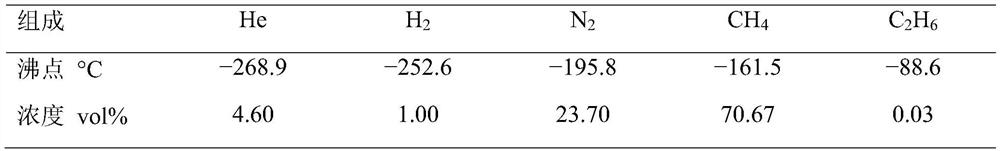

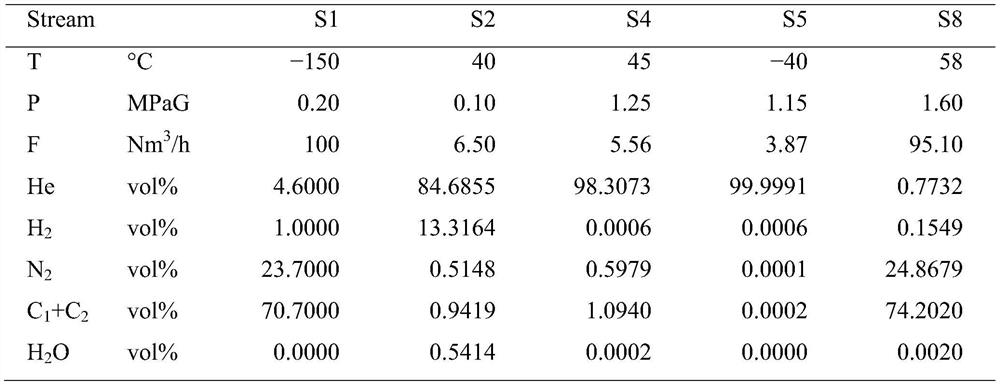

[0017] Example 1 is aimed at the helium-enriched natural gas liquefaction tail gas produced by a certain natural gas liquefaction plant. The tail gas composition is shown in Table 1, and the average tail gas flow rate is 100Nm 3 / h, using the multi-technology integration process of the present invention including separation units such as multi-stage membrane separation, catalytic oxidation, compression condensation, temperature swing adsorption and low temperature pressure swing adsorption, the principle flow structure is as follows figure 1 As shown, high-purity helium with a purity exceeding 99.999vol% is produced.

[0018] The helium-rich natural gas liquefaction tail gas S1 by-product of the natural gas liquefaction plant first enters the first heat exchanger 1, and after recovering the cooling capacity in the tail gas (the temperature rises from -150°C to 20°C), it enters the first compressor 2 for pressurization (1.75MPaG) enters the multi-stage membrane separation unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com