Active carbon catalyst loaded with copper-containing high-entropy alloy for acetylene hydrochlorination reaction and preparation method and application of active carbon catalyst

A technology for acetylene hydrochlorination and catalysts, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., and can solve problems affecting activity and stability, and expensive prices , achieve the effect of improving reactivity, low price and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

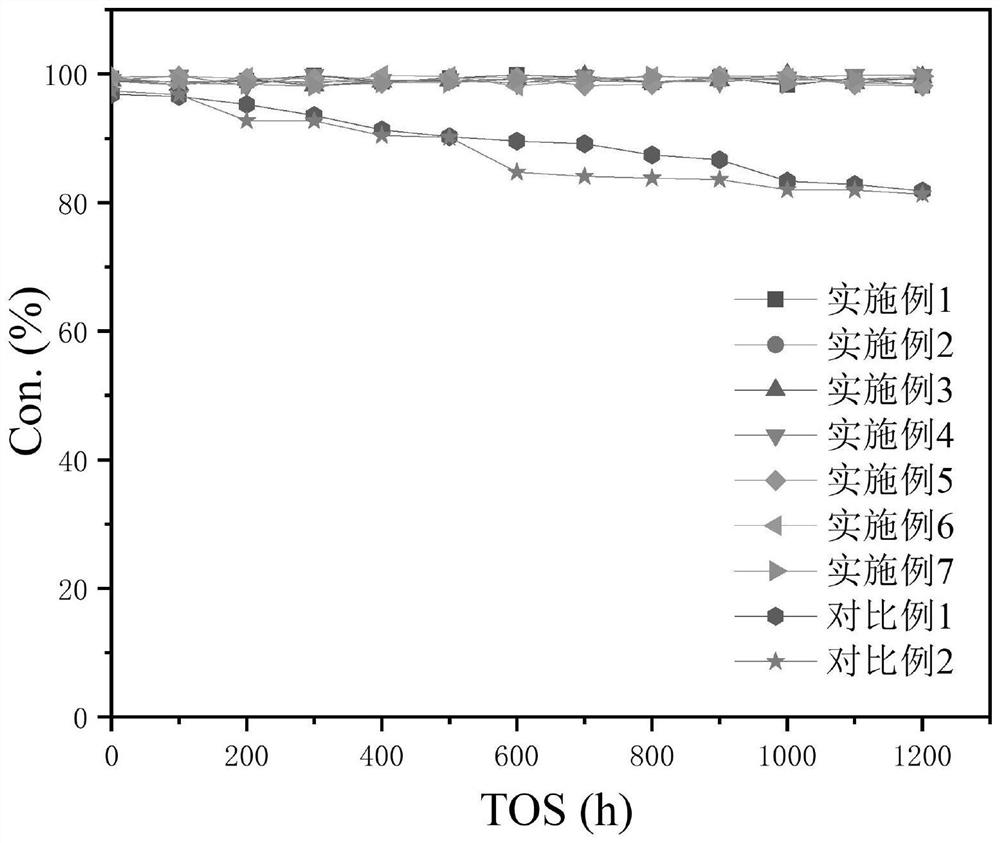

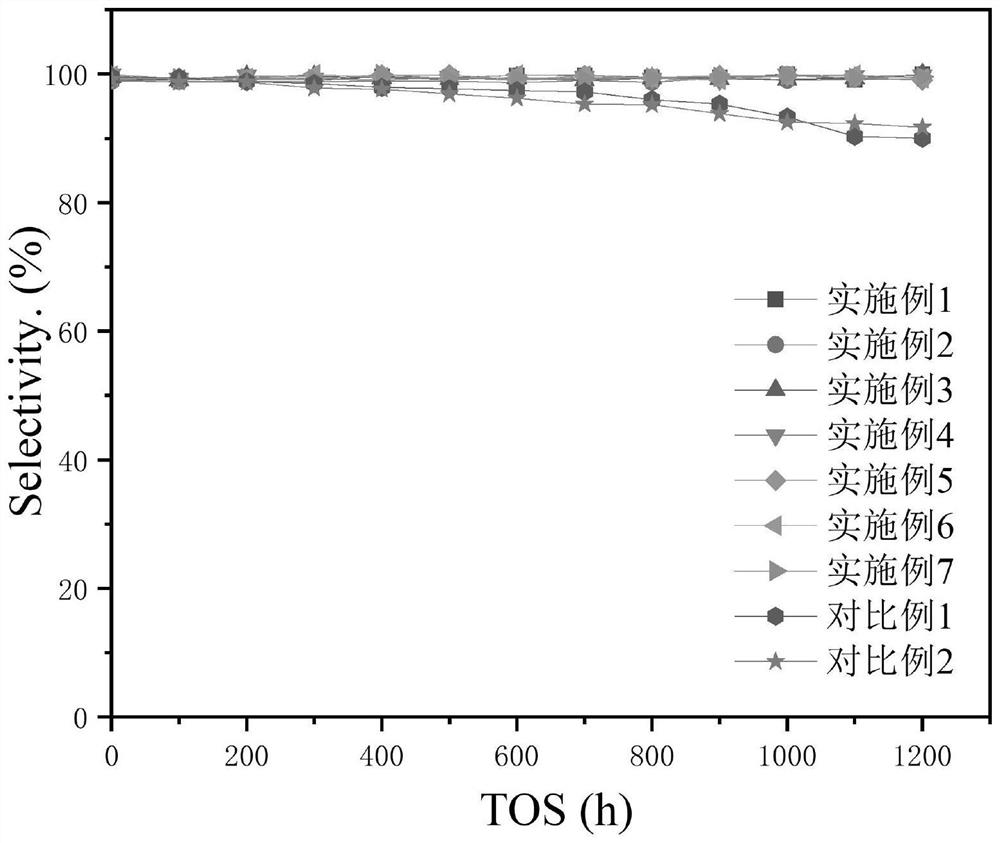

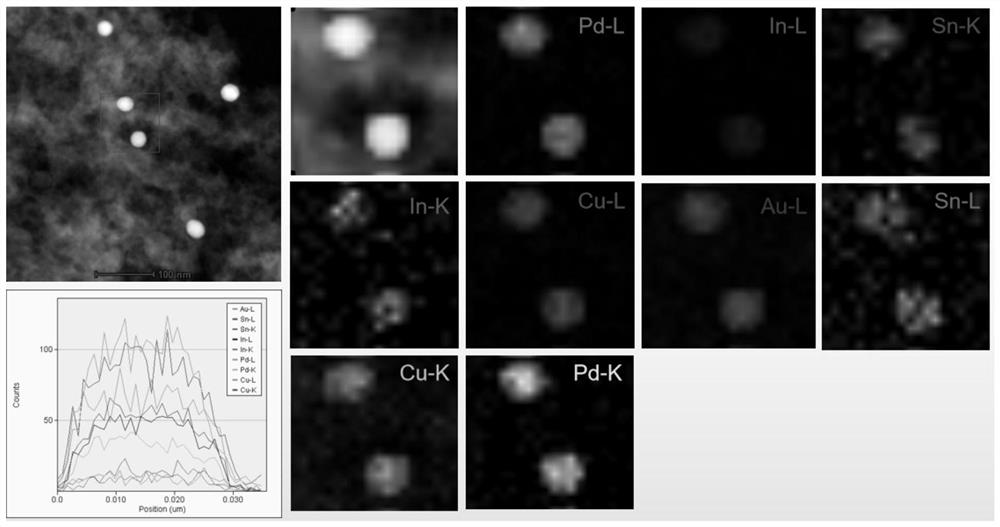

Examples

Embodiment 1

[0042] Select columnar activated carbon as the carrier, the particle size is 20 mesh, and the specific surface area is 1000m 2 / g, pore volume 1mL / g.

[0043] Dissolve 41.92g of copper chloride, 0.015g of gold chloride, 22g of cobalt chloride, 50g of aluminum chloride, and 25.54g of zirconium chloride in absolute ethanol, stir to make it evenly mixed, and then dissolve the mixture at 30°C Add it dropwise onto 100g of dry activated carbon carrier, then place this mixture in an electromagnetic stirrer, set the magnetic field strength to 50T, and the treatment time is 1h, then take the mixture out of the electromagnetic stirrer, soak it for 12h, and then place it at 120 After drying at ℃ for 10 hours, a catalyst precursor containing five metals can be obtained, wherein the copper loading is 20%, the gold loading is 0.01%, and the cobalt, aluminum, and zirconium loadings are all 10%.

[0044] Then put the precursor into the electromagnetic heating furnace for rapid temperature ri...

Embodiment 2

[0047] Select the same columnar activated carbon as the carrier in Example 1.

[0048] Dissolve 90g of copper nitrate, 0.03g of gold chloride, 22g of nickel chloride, 50g of aluminum chloride, and 25.54g of zirconium chloride in absolute ethanol, stir to make it evenly mixed, and then add the mixture dropwise at 30°C Put the mixture on 100g of dry activated carbon carrier, and then put this mixture in an electromagnetic stirrer, set the magnetic field strength to 100T, and the treatment time is 1h. After drying for 10 hours, a catalyst precursor containing five metals can be obtained, wherein the copper loading is 30%, the gold loading is 0.02%, and the nickel, aluminum, and zirconium loadings are all 10%.

[0049] Then put the precursor into the electromagnetic heating furnace for rapid temperature rise treatment under the air atmosphere. First, the temperature was raised to 300 °C at a heating rate of 60 °C / min, and then cooled to room temperature naturally, and then taken o...

Embodiment 3

[0052] Select the same columnar activated carbon as the carrier in Example 1.

[0053] Dissolve 37.5g of copper sulfate, 0.017g of platinum chloride, 44g of nickel chloride, 100g of aluminum chloride, and 51.08g of zirconium chloride in absolute ethanol, stir to make it evenly mixed, and then drop the mixed liquid at 30°C Add it to 100g of dry activated carbon carrier, then put this mixture in an electromagnetic stirrer, set the magnetic field strength to 200T, and the treatment time is 1h, then take the mixture out of the electromagnetic stirrer, soak for 12h, and then After drying for 10 hours under the same conditions, a catalyst precursor containing five metals can be obtained, the loading of copper is 15%, the loading of platinum is 0.01%, and the loading of nickel, aluminum, and zirconium is 20%.

[0054] Then put the precursor into the electromagnetic heating furnace for rapid temperature rise treatment. First, the temperature was raised to 400 °C at a heating rate of 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com