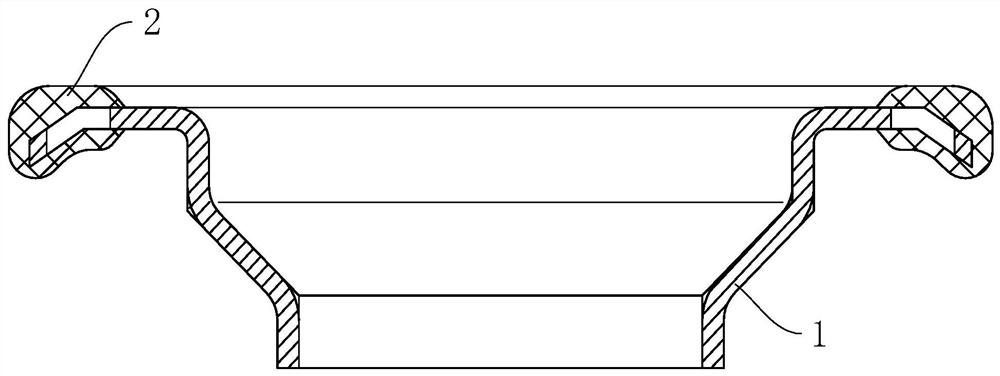

Rubber sealing valve and production process thereof

A technology of rubber seals and valves, which is applied in the direction of engine seals, conjugated synthetic polymer artificial filaments, fiber types, etc., can solve problems such as cumbersome procedures, achieve simplification of preparation processes, improve various mechanical properties, and simplify production processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0080] The following parts by mass of raw materials are needed to prepare 1 kg of self-healing fiber:

[0081] Polyacrylonitrile 0.48kg;

[0082] Polyvinylpyrrolidone 0.12kg;

[0083] Dicyclopentadiene 0.4kg.

[0084] The preparation process of self-repairing fiber includes the following process steps:

[0085] Step 1, spinning, put polyacrylonitrile and polyvinylpyrrolidone into DMF to dissolve completely, configure the spinning solution with a concentration of 14wt% for spinning, the diameter of the spinneret hole on the spinneret plate is 50 μm, and the diameter of the spinneret hole The diameter of the inlet pipe was 30 μm, and a hollow fiber with an outer diameter of 50 μm and an inner diameter of 30 μm was obtained.

[0086] Step 2, passing through a water bath, that is, passing the hollow fiber obtained in step 1 through a water bath, the temperature of the water bath is 60° C., and the time of the water bath is 30 minutes, and then taken out and dried at 60° C. for ...

preparation example 2

[0090] The difference between Preparation Example 2 and Preparation Example 1 is that step 2 adopts the treatment method of alkali reduction instead of the treatment method of water bath, and the specific steps are as follows,

[0091] Step 2, alkali reduction treatment, that is, put the hollow fiber obtained in step 1 into a 10wt% concentration of sodium hydroxide solution, the treatment time is 10 minutes, and the treatment temperature is 90 ° C. After the treatment is completed, take it out, wash and dry it, and the porous fiber .

preparation example 3

[0093] The difference between Preparation Example 3 and Preparation Example 2 is that the following parts by mass of raw materials are required to prepare 1 kg of self-repairing fiber:

[0094] Polyacrylonitrile 0.6kg;

[0095] Polyvinylpyrrolidone 0.1kg;

[0096] Dicyclopentadiene 0.3kg.

[0097] In step 1, the diameter of the spinneret hole on the spinneret is 40 μm, and the diameter of the inlet tube is 20 μm, to obtain a hollow fiber with an outer diameter of 40 μm and an inner diameter of 20 μm.

[0098] In step 4, the impregnated fibers obtained in step 3 are cut into fibers with a length of 0.9 mm to obtain self-repairing fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com