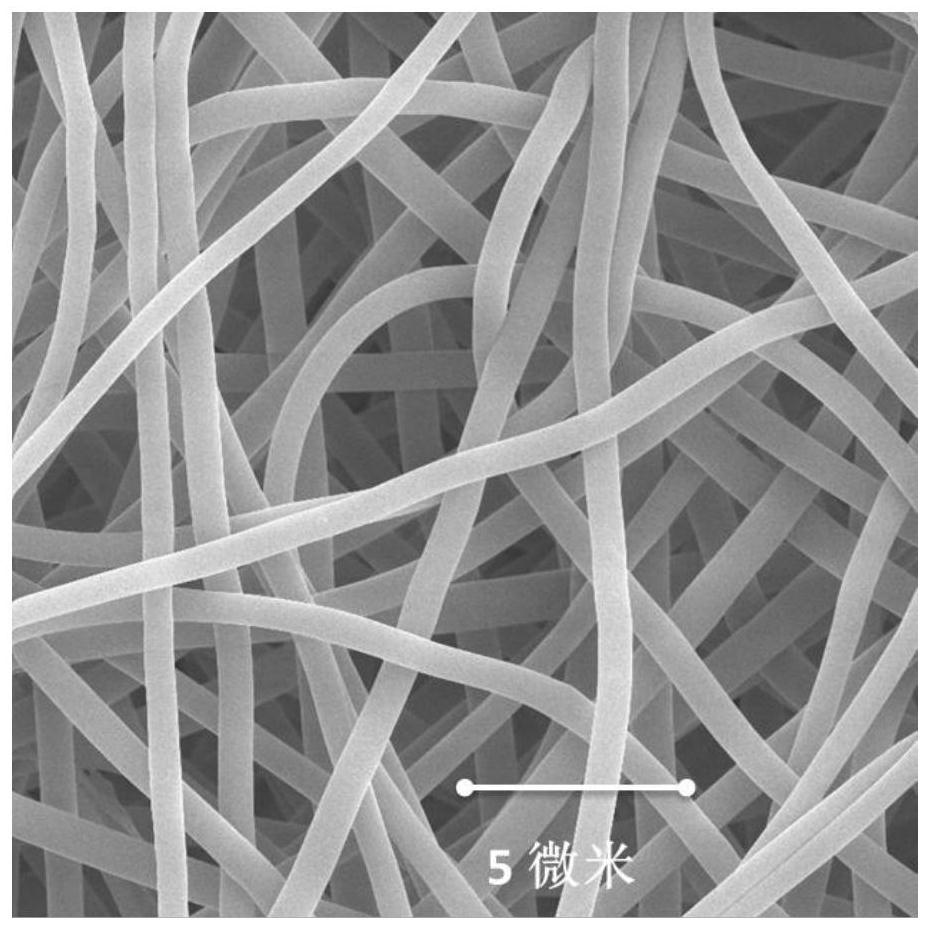

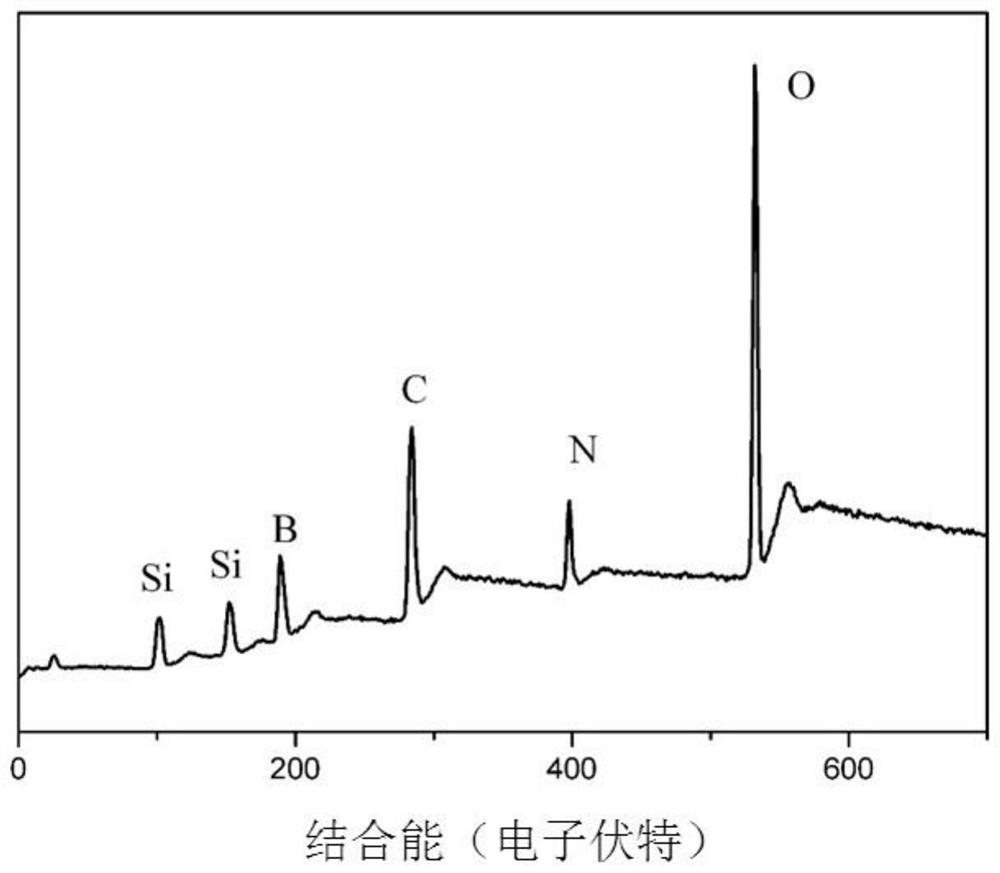

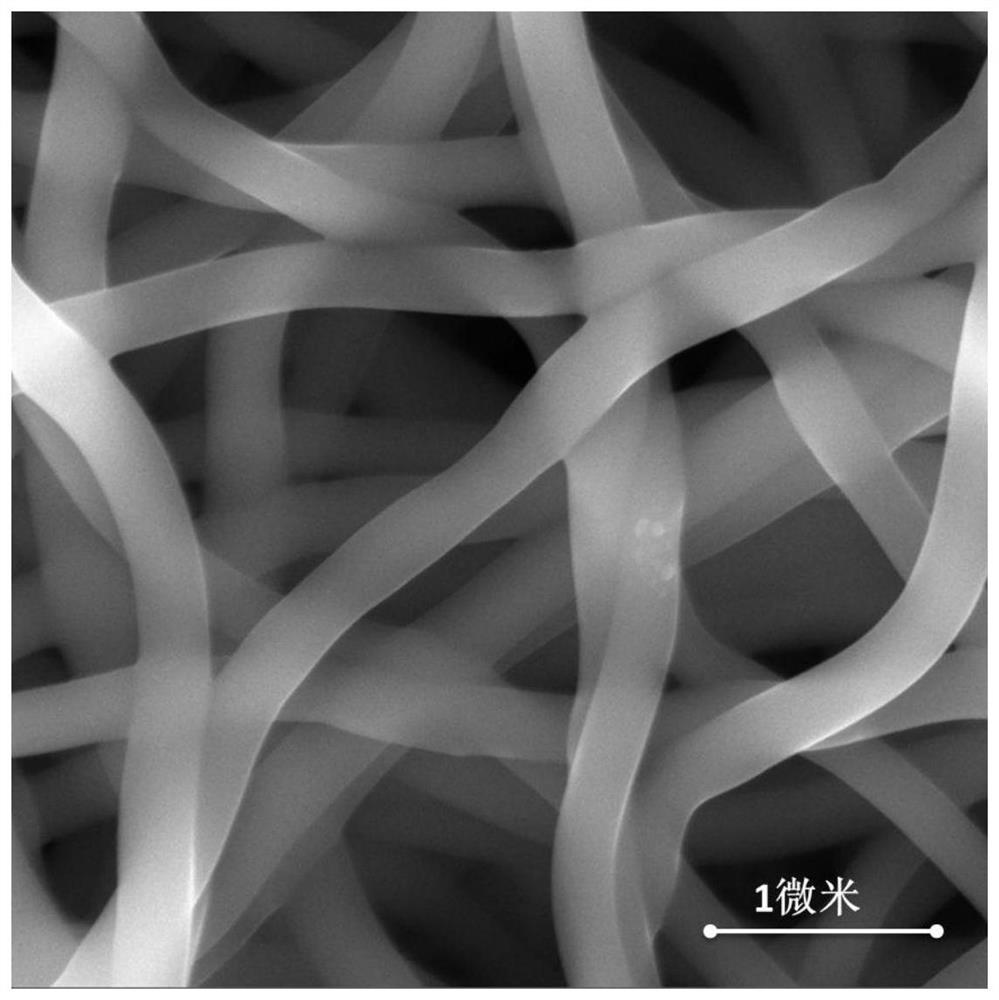

Preparation method of superfine-diameter SiBCN ceramic fibers

A ceramic fiber and superfine fiber technology, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of complex process and unfavorable large-scale preparation of SiBCN superfine fiber, and achieve high synthesis yield and simple synthesis method , The effect of high ceramic productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of superfine diameter SiBCN ceramic fiber, comprises the following steps:

[0035] The preparation of spinning solution: (1) weigh decaborane B respectively 10 h 14 , 1,3-bis(aminopropyl)tetramethyldisiloxane and polyvinylpyrrolidone, the ratio of the amount of substances is 1:1.1:0.5, decaborane and 1,3-bis(aminopropyl) tetra Methyl disiloxane was dissolved in tetrahydrofuran to obtain decaborane solution and diamine solution, and polyvinylpyrrolidone was dissolved in N,N'-dimethylformamide to obtain polyvinylpyrrolidone solution; (2) by constant pressure separatory funnel to B 10 h 14 Add diamine solution dropwise into the solution, react at room temperature for more than 10 hours, and vacuum distill for 8 hours under the condition of constant temperature water bath at 60°C; (3) Add polyvinylpyrrolidone solution and ultrasonicate for 20 minutes to obtain a transparent solution, which is the spinning solution.

[0036] Preparation of na...

Embodiment 2

[0039] A kind of preparation method of superfine diameter SiBCN ceramic fiber, comprises the following steps:

[0040] Preparation of spinning solution: (1) Weigh decaborane, hexamethyldisilazane and polyvinylpyrrolidone respectively, the ratio of the amount of substances is 1:1.2:1.0, decaborane and hexamethyldisilazane Azane was dissolved in tetrahydrofuran to obtain decaborane solution and diamine solution, and polyvinylpyrrolidone was dissolved in N,N'-dimethylformamide to obtain polyvinylpyrrolidone solution; (2) through a constant pressure separatory funnel to B 10 h14 Add diamine solution dropwise to the solution, react at room temperature for more than 10 hours, and vacuum distill for 12 hours under the condition of constant temperature water bath at 60°C; (3) Add polyvinylpyrrolidone solution and ultrasonicate for 20 minutes to obtain a transparent solution, which is the spinning solution.

[0041] Preparation of nanofibers: (4) First, the spinning solution is poured...

Embodiment 3

[0044] A kind of preparation method of superfine diameter SiBCN ceramic fiber, comprises the following steps:

[0045] Preparation of spinning solution: (1) Weigh decaborane, [3-(trimethoxysilyl)propyl]ethylenediamine and polyvinylpyrrolidone respectively, the ratio of the amount of substances is 1:1.2:0.8, Decaborane and [3-(trimethoxysilyl)propyl]ethylenediamine were dissolved in tetrahydrofuran to obtain decaborane solution and diamine solution, and polyvinylpyrrolidone was dissolved in N,N'-dimethylformaldehyde Obtain polyvinylpyrrolidone solution in amide; (2) pass constant pressure separatory funnel to B 10 h 14 Add diamine solution dropwise to the solution, react at room temperature for more than 10 hours, and vacuum distill for 10 hours under the condition of constant temperature water bath at 60°C; (3) Add polyvinylpyrrolidone solution and ultrasonicate for 20 minutes to obtain a transparent solution, which is the spinning solution.

[0046] Preparation of nanofiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com