Preparation method and application of CuO-ZnO flower-like structure composite sensitive material

A composite sensitive, flower-like structure technology, applied in the analysis of materials, material resistance, material analysis by electromagnetic means, etc., can solve the problems of large and cumbersome detection instruments, difficult real-time online monitoring, limited application, etc., to achieve good detection characteristics, Simple and feasible operation, accelerate the effect of fast transmission and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of ZnO flower-like structure materials

[0033] Step 1: Weigh 4.76 g of zinc nitrate and 4.82 g of urea in sequence, dissolve them in a mixed solution of 160 mL of distilled water and ethylene glycol (volume ratio 1:1), and stir magnetically for 30 minutes to form a clear solution. Hydrothermal synthesis of precursor reaction solution.

[0034] Step 2: Transfer the precursor reaction solution prepared in Step 1 into a polytetrafluoroethylene-lined stainless steel autoclave with a filling degree of 80%, and seal it.

[0035] Step 3: Place the reaction kettle in Step 2 in an oven, keep it warm at 100° C. for 12 hours, and then cool it down.

[0036] Step 4: Centrifuge the reactant solution prepared in Step 3 to obtain a precipitate, and then use distilled water and absolute ethanol to alternately centrifuge and wash 6 times to wash away residual ions in the reaction solution.

[0037] Step 5: Place the product of Step 4 in a drying oven at a constant tem...

Embodiment 2

[0043] (1) Preparation of CuO-ZnO flower-like structure composite sensitive material

[0044] Step 1: Weigh 4.76 g of zinc nitrate, 0.03 g of copper nitrate, and 4.82 g of urea in sequence, dissolve them in a mixed solution of 160 mL of distilled water and ethylene glycol (volume ratio 1:1), stir magnetically for 30 minutes, and form a clear The solution is prepared as a hydrothermal synthesis precursor reaction solution.

[0045] Steps 2, 3, 4, 5 and 6 are the same as in Example 1.

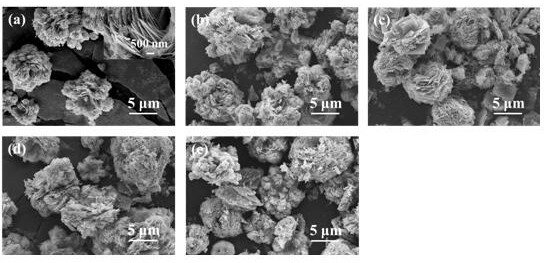

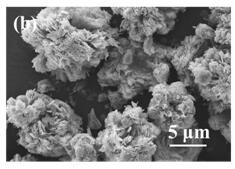

[0046] (2) Structural characterization of CuO-ZnO flower-like composite sensitive materials

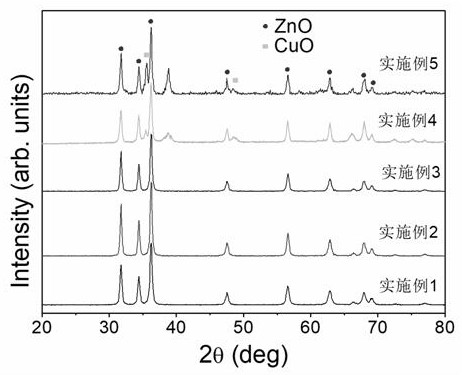

[0047] The crystal structure of the product was characterized by XRD powder diffractometer (XRD, PANalytical X’Pert Pro). From figure 1 It can be seen that in addition to the monoclinic ZnO characteristic peak, there is no CuO characteristic peak in the sample, which may be due to the lower CuO content and smaller particle size. The characteristic peaks of product diffraction are all sharp without any ...

Embodiment 3

[0049] (1) Preparation of CuO-ZnO flower-like structure composite sensitive material

[0050] Step 1: Weigh 4.76 g of zinc nitrate, 0.09 g of copper nitrate, and 4.82 g of urea in turn, dissolve them in a mixed solution of 160 mL of distilled water and ethylene glycol (volume ratio 1:1), and stir magnetically for 30 minutes until complete Dissolved to prepare a hydrothermal synthesis precursor reaction solution. Dissolve it in a mixed solution prepared with 40 mL distilled water and 40 mL ethylene glycol, and stir it magnetically for 30 minutes to form a clear solution, which is prepared as a reaction solution for the precursor of hydrothermal synthesis.

[0051] Steps 2, 3, 4, 5 and 6 are the same as in Example 1.

[0052] (2) Structural characterization of CuO-ZnO flower-like composite sensitive materials

[0053] The crystal structure of the product was characterized by XRD powder diffractometer (XRD, PANalytical X’Pert Pro). From figure 1 It can be seen that in additio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com