Aqueous zinc ion battery electrolyte containing additive, preparation method of aqueous zinc ion battery electrolyte and battery

A technology for preparing zinc ion batteries and electrolytes, which is applied to aqueous electrolytes, secondary batteries, circuits, etc., can solve problems such as short circuit, low Coulombic efficiency, loss of active materials, etc., and achieves simple process, improved Coulombic efficiency, and improved energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

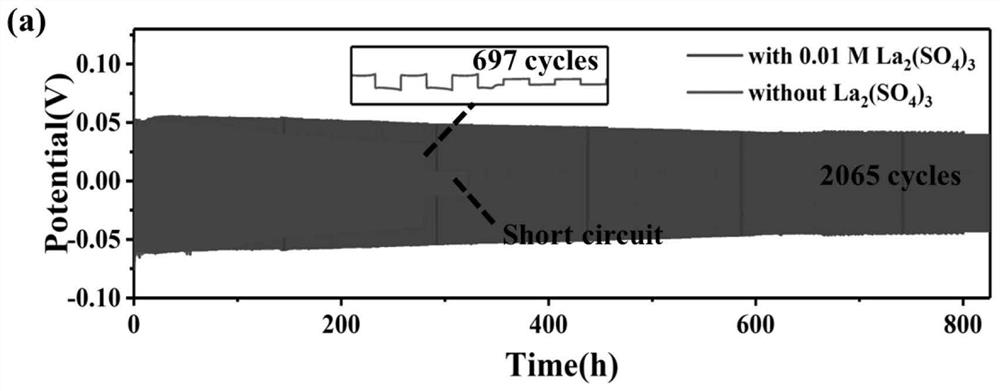

Embodiment 1

[0040] At room temperature, completely dissolve 14.38 g of zinc sulfate heptahydrate in 50 mL of deionized water, then add 0.283 g of lanthanum sulfate (0.01 mol / L), dissolve evenly, and set aside. Zinc foil is used as the positive and negative electrodes, and glass fiber is used as the diaphragm to assemble the water system zinc-ion symmetrical battery. Sodium vanadate is used as the positive electrode, zinc foil is used as the negative electrode, and glass fiber is used as the diaphragm to assemble the aqueous zinc-ion full battery. Preparation of positive and negative electrodes and assembly of coin-type CR2032 symmetrical batteries and NaV 3 o 8 1.5H 2 O / / Zn full battery, XRD, SEM sample preparation, and open circuit voltage test procedures are the same as in Comparative Example 1. Figure 5 The XRD pattern shows that all the characteristic peaks match well with the standard phase of metal Zn (PDF#04-0831), and no impurity peaks are observed, proving that La 3+ Will ex...

Embodiment 2

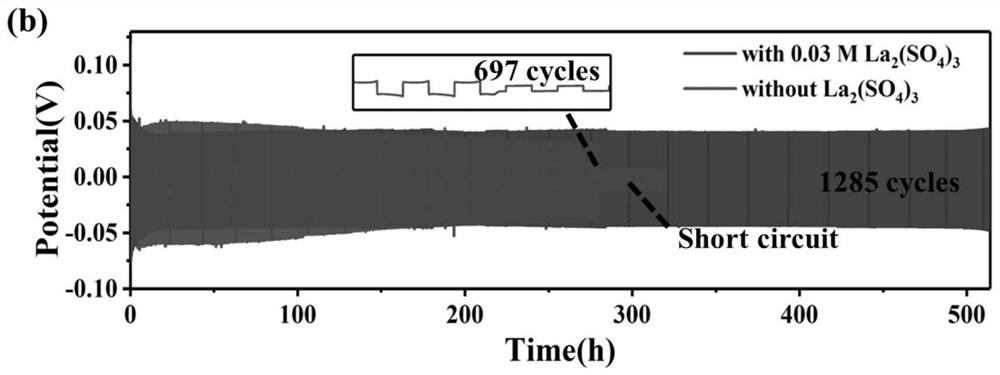

[0042] At room temperature, completely dissolve 14.38 g of zinc sulfate heptahydrate in 50 mL of deionized water as an electrolyte, then add 0.849 g of lanthanum sulfate (0.03 mol / L), dissolve evenly, and set aside. Zinc foil is used as the positive and negative electrodes, and glass fiber is used as the diaphragm to assemble the water system zinc-ion symmetrical battery. Manganese dioxide is used as the positive electrode, zinc foil is used as the negative electrode, and glass fiber is used as the diaphragm to assemble the water-based zinc-ion full battery. Preparation of positive and negative electrodes and assembly of coin-type CR2032 symmetrical batteries and MnO 2 / / Zn full battery, XRD, SEM sample preparation, and open circuit voltage test procedures are the same as in Comparative Example 1. The electrochemical test results are shown in Table 1. The water-based zinc-ion symmetric battery was tested at 1, 5 and 10 mA cm -2 , the cycle life is as high as 308, 602 and 586...

Embodiment 3

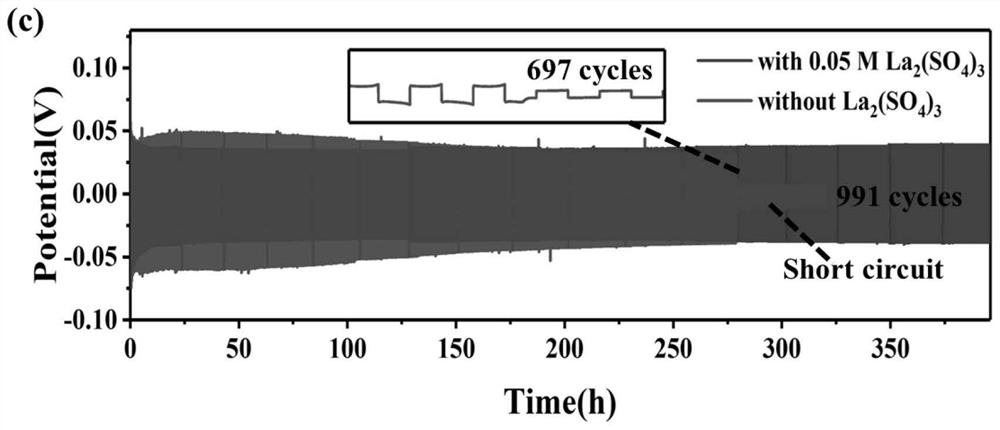

[0044] At room temperature, completely dissolve 14.38 g of zinc sulfate heptahydrate in 50 mL of deionized water, then add 0.849 g of lanthanum sulfate (0.03 mol / L), dissolve evenly, and set aside. Sodium vanadate is used as the positive electrode, zinc foil is used as the negative electrode, and glass fiber is used as the diaphragm to assemble the aqueous zinc-ion full battery. Preparation of positive and negative electrodes and NaV 3 o 8 1.5H 2 The assembly of O / / Zn full cells is the same as in Comparative Example 1. Electrochemical test results are shown in Table 1 and Figure 9 As shown, the aqueous Zn-ion full battery is at 1A·g -1 , the Coulombic efficiency is 99% and the capacity retention after 100 cycles is 92%, and Figure 10 It also shows a small impedance, which is beneficial to reduce the full cell polarization voltage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com