Method for preparing sodium persulfate through direct electrooxidation

A technology of sodium persulfate and electro-oxidation, applied in electrolysis process, non-precious metal oxide coating, electrode, etc., can solve the problems of low current efficiency, low current efficiency, large raw material consumption, etc., achieve long service life and simplify production Process, effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

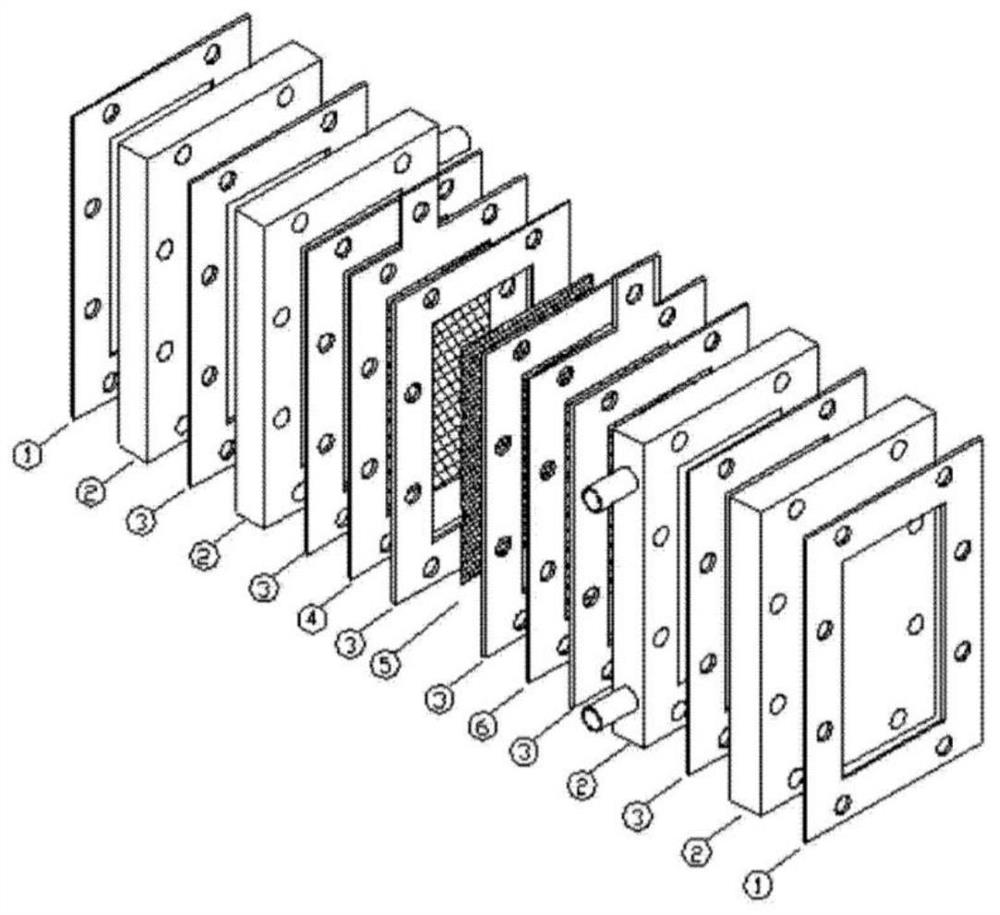

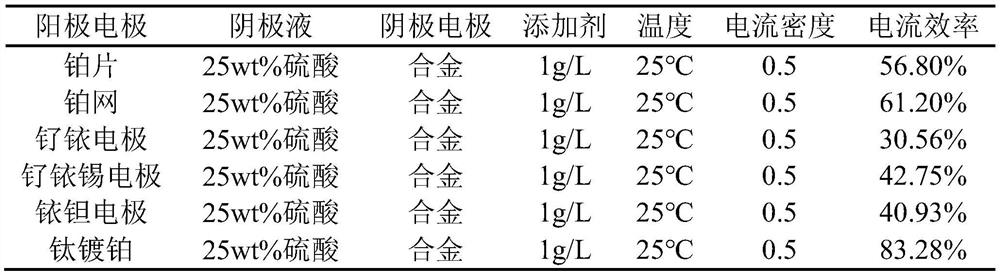

[0026] The electrolytic cell adopts a structure such as figure 1 In the plate-and-frame electrolytic cell shown, the anode titanium-plated electrode is prepared as follows: metal titanium is selected as the substrate, and there is often a layer of dense oxide film on the surface of pure titanium, so it is firstly polished with 400-mesh metallographic sandpaper until Until the metal surface shows a uniform silver-white metallic luster, put the polished metal flakes into an ultrasonic cleaner for cleaning. After cleaning for 30 minutes, take them out and blow dry them. Alkali washing in NaOH lye, take it out after 2 hours, continue to put it in an ultrasonic cleaner for cleaning, take it out after 20 minutes and put it into an oxalic acid solution with a mass fraction of 25% for etching operation, so that the surface appears numb. After 2 hours, take it out and rinse it thoroughly with distilled water and place it in an alcohol solution with a mass fraction of 75% for later use....

Embodiment 2

[0034] Add an anolyte composed of sodium sulfate 280g / L and sulfuric acid 200g / L to the anode electrolyzer, add 25wt% dilute sulfuric acid solution to the cathode electrolyzer, the electrolysis temperature is 35°C, and the current density is 0.5A / m 2 , using a self-made titanium platinum-plated electrode as the anode, the cathode as a self-made alloy electrode, the anode inhibitor as 1g / L NaCl, electrolysis for 1.5h, the anolyte was exported, distilled and dried to obtain sodium persulfate crystals, the electrolytic cell pressure was 3.9v, The current efficiency was 78.23%, and the concentration of sodium persulfate was 150.49g / L.

Embodiment 3

[0036] Add an anolyte composed of sodium sulfate 290g / L and sulfuric acid 220g / L to the anode electrolyzer, add 25wt% dilute sulfuric acid solution to the cathode electrolyzer, the electrolysis temperature is 30°C, and the current density is 0.5A / m 2 , using a self-made titanium platinum-plated electrode as the anode, the cathode as a self-made alloy electrode, the anode inhibitor as 1g / L NaCl, electrolysis for 1.5h, the anolyte was exported, distilled and dried to obtain sodium persulfate crystals, the electrolytic cell pressure was 3.9v, The current efficiency was 78.23%, and the concentration of sodium persulfate was 150.49g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com