Carbazolyl porous carbon/polyaniline composite electrode material and preparation method thereof

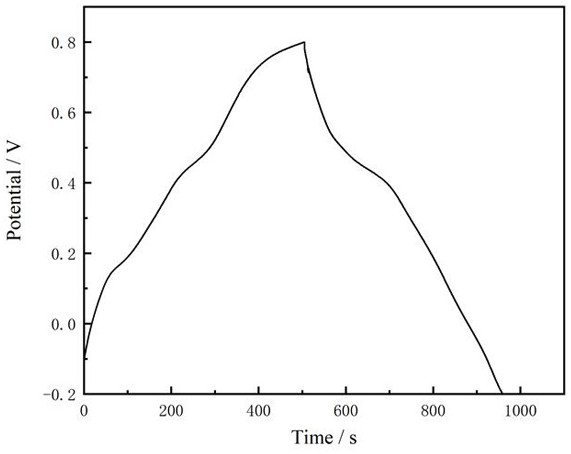

A composite electrode, carbazole-based technology, applied in the field of carbazole-based porous carbon/polyaniline composite electrode materials and their preparation, can solve the problem of poor cycle stability and rate performance, poor electrical conductivity, and power density not as good as electric double-layer capacitors, etc. problems, to achieve the effect of enriching active sites, enhancing surface wettability, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

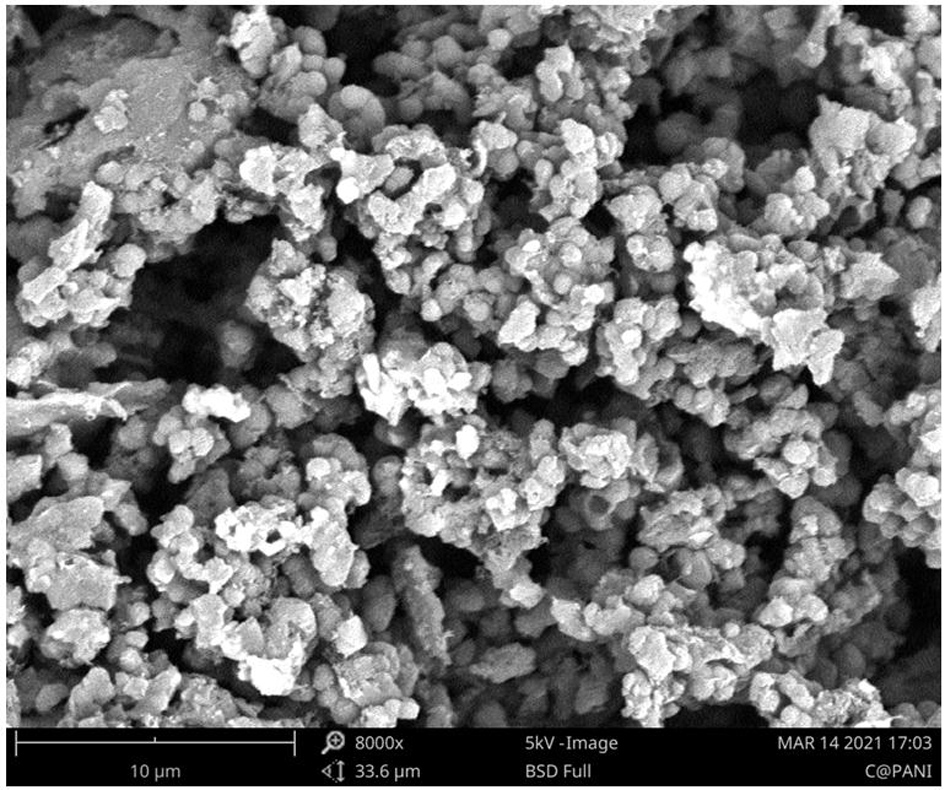

[0022] (1) 30 mmol of carbazole monomer was dissolved in 120 mL of 1,2-dichloroethane, then 60 mmol of dimethoxyethane was added to stir well, and then 45 mmol of anhydrous trichloride, while stirring The temperature was raised to 80 ° C, and the product was filtered at 80 ° C for 24 hours, and the product was filtered through methanol and filtered until the filtrate was close to colorless, and the carbazole-based superblyflial polymer was obtained by vacuum at 80 ° C.

[0023] (2) Take 1 g of the product obtained by step (1) and 4 g of potassium hydroxide in 300 ml absolute ethanol, stirring to 60 ° C to the solvent to evaporate, placing the solid mixture in the tube furnace, in nitrogen Under the atmosphere, it was raised to 700 ° C at a temperature rise rate of 5 ° C / min, and the high temperature of 700 ° C was kept in 1.5 hours, cooled to room temperature, and the pyrolysis product was washed, washed, washed, dried to obtain a carbazole-based porous carbon;

[0024] (3) Take...

Embodiment 2

[0026] (1) 30 mmol carbazole monomer was dissolved in 120 mL of 1,2-dichloroethane, then 60 mmol of dimethoxyethane was added well, and then 60 mmol of anhydrous trichloride, stirred while stirring. The temperature was raised to 80 ° C, and the product was filtered at 80 ° C for 24 hours, and the product was filtered through methanol and filtered until the filtrate was close to colorless, and the carbazole-based superblyflial polymer was obtained by vacuum at 80 ° C.

[0027] (2) The product obtained by step (1) is dispersed from 4 g of potassium hydroxide in 300 ml of anhydrous ethanol, and the stirring to 60 ° C is stirred to the solvent, and the solid mixture is placed in a tube furnace, in a nitrogen atmosphere Next, the temperature rise rate of 5 ° C / min was raised to 700 ° C, and the high temperature of 700 ° C was kept intracted for 1.5 hours, cooled to room temperature, and the pyrolysis product was washed, washed, washed, dried to obtain a carbazole-based porous carbon....

Embodiment 3

[0030] (1) 22.5 mmol of carbazole monomer was dissolved in 120 ml of 1,2-dichloroethane, then 67.5 mmol of dimethoxyethane, stir well, add 45 mmol of anhydrous carbide, stirred while stirring The temperature was warmed to 80 ° C, reacted at 80 ° C for 24 hours, and the product was filtered through methanol ultrasound and filtered to the filtrate approached colorless, and the carbazole-based superblyflial polymer was obtained after vacuum at 80 ° C.

[0031] (2) The product obtained by step (1) is dispersed from 4 g of potassium hydroxide in 300 ml of anhydrous ethanol, and the stirring to 60 ° C is stirred to the solvent, and the solid mixture is placed in a tube furnace, in a nitrogen atmosphere Next, the temperature rise rate of 5 ° C / min was raised to 700 ° C, and the high temperature of 700 ° C was kept intracted for 1.5 hours, cooled to room temperature, and the pyrolysis product was washed, washed, washed, dried to obtain a carbazole-based porous carbon.

[0032] (3) Take ...

PUM

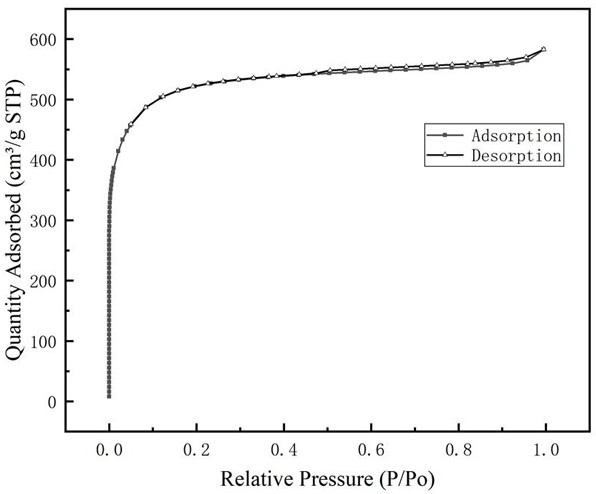

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com