Silver-copper alloy material for manufacturing commutator copper sheet

A silver-copper alloy and alloy material technology, applied in conductive materials, conductive materials, metal/alloy conductors, etc., to achieve the effect of improving motor life, good elasticity, and strengthening alloy properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

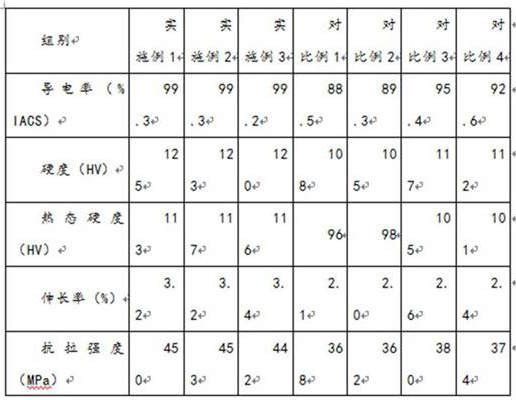

Examples

preparation example Construction

[0020] Wherein, the preparation method of the silver-copper alloy material sheet includes: melting Ag, Pt, Cu and Mg raw materials through a ZGJL0.01-40-4 type vacuum medium frequency induction furnace in an atmospheric environment to obtain an alloy ingot, and using the alloy ingot to After grinding with sandpaper, it is rolled on a rolling mill, and after multi-pass rolling and intermediate recrystallization annealing, it is finally rolled into a thin plate with a thickness of 0.3~0.4mm;

[0021] The annealing at N 2 Under protection, the annealing temperature is 850~1000℃, the holding time is 2~3 h, and the thickness of the alloy sheet is reduced by 35~40% every time an annealing is performed.

[0022] Wherein, the internal oxidation reaction includes: cutting the silver-copper alloy material thin plate into an alloy round thin slice, and cutting the thin slice into an alloy with O 2 The AgPtCuOMgO alloy material is obtained by performing an internal oxidation reaction in ...

Embodiment 1

[0026] Provided in this embodiment is a silver-copper alloy material for commutator copper sheet production, including Ag, Pt, Cu and Mg metal materials with a weight ratio of 1:0.15:9:0.25, the silver-copper alloy material The Ag, Pt, Cu and Mg raw materials are smelted through a vacuum induction melting furnace to obtain an AgPtCuMg alloy material, which is then treated by an internal oxidation reaction and rolled into an alloy strip with an oxygen-free copper base material; the Ag, Pt, Cu and The purity of the Mg metal material is 99.99%; the specific preparation method is as follows:

[0027] (1) The preparation method of the silver-copper alloy material sheet: the alloy ingot is obtained by melting the Ag, Pt, Cu and Mg raw materials through the ZGJL0.01-40-4 vacuum intermediate frequency induction furnace in the atmospheric environment, and the alloy ingot is polished with sandpaper After rolling on the rolling mill, through multi-pass rolling and intermediate recrystall...

Embodiment 2

[0031] Provided in this embodiment is a silver-copper alloy material for commutator copper sheet production, including Ag, Pt, Cu and Mg metal materials with a weight ratio of 2:0.2:10:0.3, the silver-copper alloy material The Ag, Pt, Cu and Mg raw materials are smelted through a vacuum induction melting furnace to obtain an AgPtCuMg alloy material, which is then treated by an internal oxidation reaction and rolled into an alloy strip with an oxygen-free copper base material; the Ag, Pt, Cu and The purity of the Mg metal material is 99.99%; the specific preparation method is as follows:

[0032](1) The preparation method of the silver-copper alloy material sheet: the alloy ingot is obtained by melting the Ag, Pt, Cu and Mg raw materials through the ZGJL0.01-40-4 vacuum intermediate frequency induction furnace in the atmospheric environment, and the alloy ingot is polished with sandpaper Carry out rolling on rolling mill afterward, through multipass rolling and intermediate rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap