Polyelectrolyte material for new energy automobile fuel cell and preparation method of polyelectrolyte material

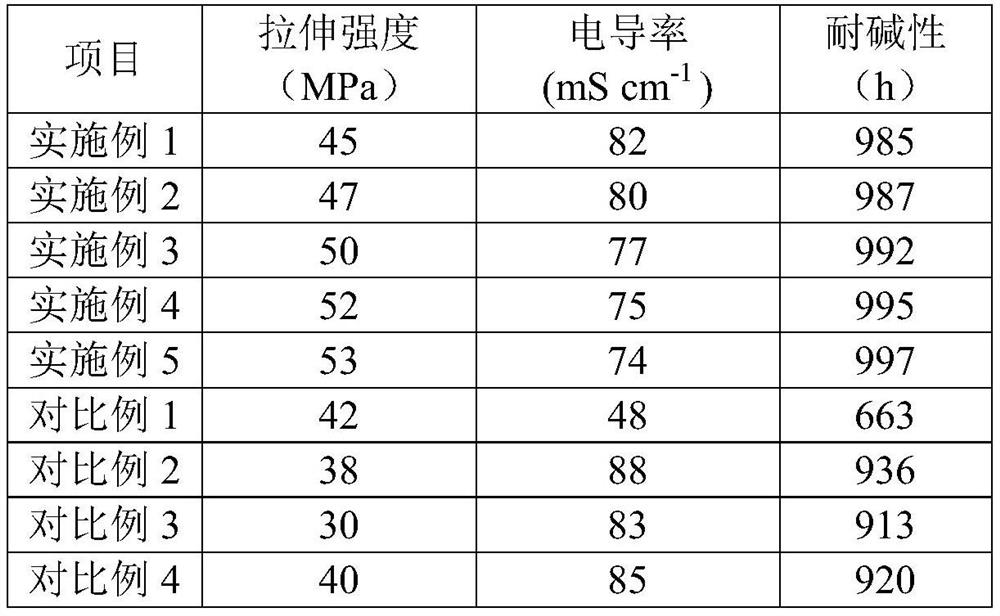

A new energy vehicle, fuel cell technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of high cost of polyelectrolyte membrane materials, comprehensive performance and performance stability need to be further improved, high price, and achieve comprehensive performance and Good performance stability, high ionic conductivity and mechanical strength, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of polyelectrolyte material for a new energy vehicle fuel cell, characterized in that the following steps are included:

[0028] Step S1, the polymerizable type is prepared based on cyclohexylimidazole containing: 1,3-bicyclic hexazole hydrochloride, 1,1,2-trifluoro-2-chloro-3-methyl-3-vinyl ring ring Butane, alkaline catalyst is added to the organic solvent, and the reaction is stirred at 35 ° C for 4 hours, and the insoluble material is removed, and the solvent is removed, and the polymerizable type cyclohexylimidazole is obtained.

[0029] Step S2, the preparation of the copolymer film: the polymerizable type formed by step S1 is based on cyclohexylimidazole, N- (4-cyano-3-trifluoromethylphenyl) methacrylamide, three (2 - Acryoyloxyethyl) isocyanurate, 5-vinyl double loop [2.2.1] hept-2-ethyl, initiator is added to the high boiling solvent, preliminary polymerization at 65 ° C under an inert gas atmosphere 1 hour, a prepolymer is formed; then the pre...

Embodiment 2

[0035] A preparation method of polyelectrolyte material for a new energy vehicle fuel cell, characterized in that the following steps are included:

[0036] Step S1, the polymerizable type is prepared based on cyclohexylimidazole containing: 1,3-bicyclic hexazole hydrochloride, 1,1,2-trifluoro-2-chloro-3-methyl-3-vinyl ring ring Butane, alkaline catalyst is added to an organic solvent, and the reaction is stirred at 38 ° C for 4.5 hours, and the insoluble material is removed, and the solvent is removed, and the polymerizable type is based on cyclohexylimidazole.

[0037] Step S2, the preparation of the copolymer film: the polymerizable type formed by step S1 is based on cyclohexylimidazole, N- (4-cyano-3-trifluoromethylphenyl) methacrylamide, three (2 - Acryoyloxyethyl) isocyanurate, 5-vinyl double loop [2.2.1] hept-2-ethyl, initiator is added to a high boiling solvent, preliminary polymerization at 68 ° C under an inert gas atmosphere 1.2 hours, a prepolymer is formed; then the p...

Embodiment 3

[0043] A preparation method of polyelectrolyte material for a new energy vehicle fuel cell, characterized in that the following steps are included:

[0044] Step S1, the polymerizable type is prepared based on cyclohexylimidazole containing: 1,3-bicyclic hexazole hydrochloride, 1,1,2-trifluoro-2-chloro-3-methyl-3-vinyl ring ring Butane, alkaline catalyst is added to an organic solvent, and the stirring reaction is stirred at 43 ° C for 5 hours, and the insoluble material is removed, and the solvent is removed, and the polymerizable type cyclohexylimidazole is obtained.

[0045] Step S2, the preparation of the copolymer film: the polymerizable type formed by step S1 is based on cyclohexylimidazole, N- (4-cyano-3-trifluoromethylphenyl) methacrylamide, three (2 - Acryoyloxyethyl) isocyanurate, 5-vinyl double loop [2.2.1] hept-2-ethyl, initiator is added to the high boiling solvent, preliminary polymerization at 70 ° C under an inert gas atmosphere 1.5 hours, a prepolymer is formed; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com