Preparation method of saturable absorber and fiber laser

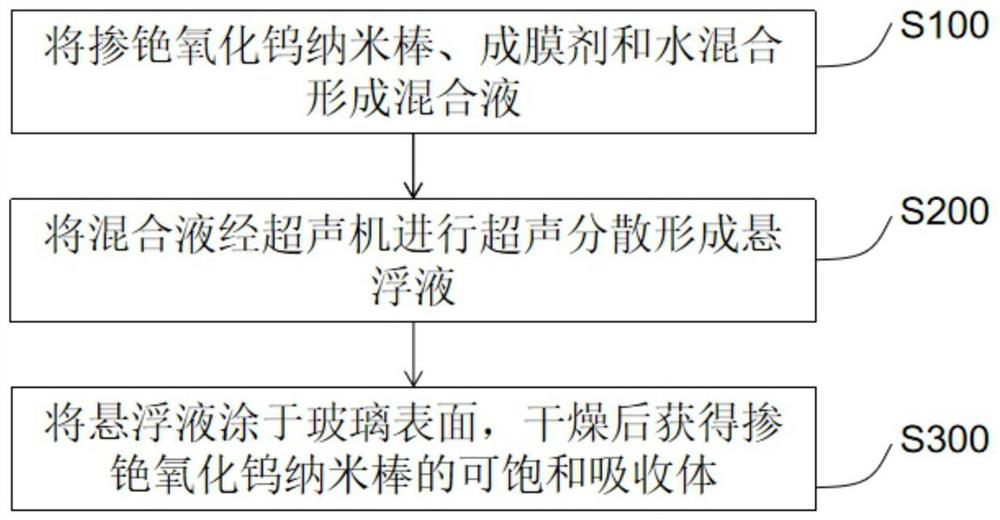

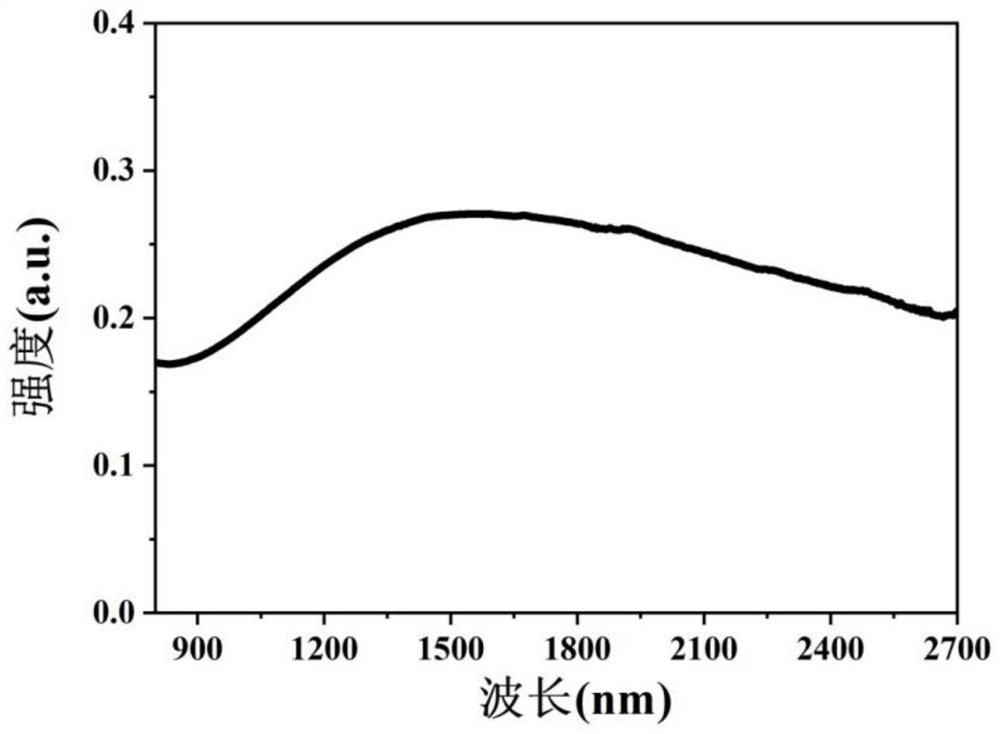

A saturable absorption, fiber laser technology, used in the preparation of saturable absorbers, saturable absorbers and laser fields, can solve the problem of easy deterioration of saturable absorber performance, affecting the stability of pulsed lasers, unfavorable for ultra-short pulses, etc. problems, to achieve the effect of reducing application costs, stabilizing laser output, and making simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

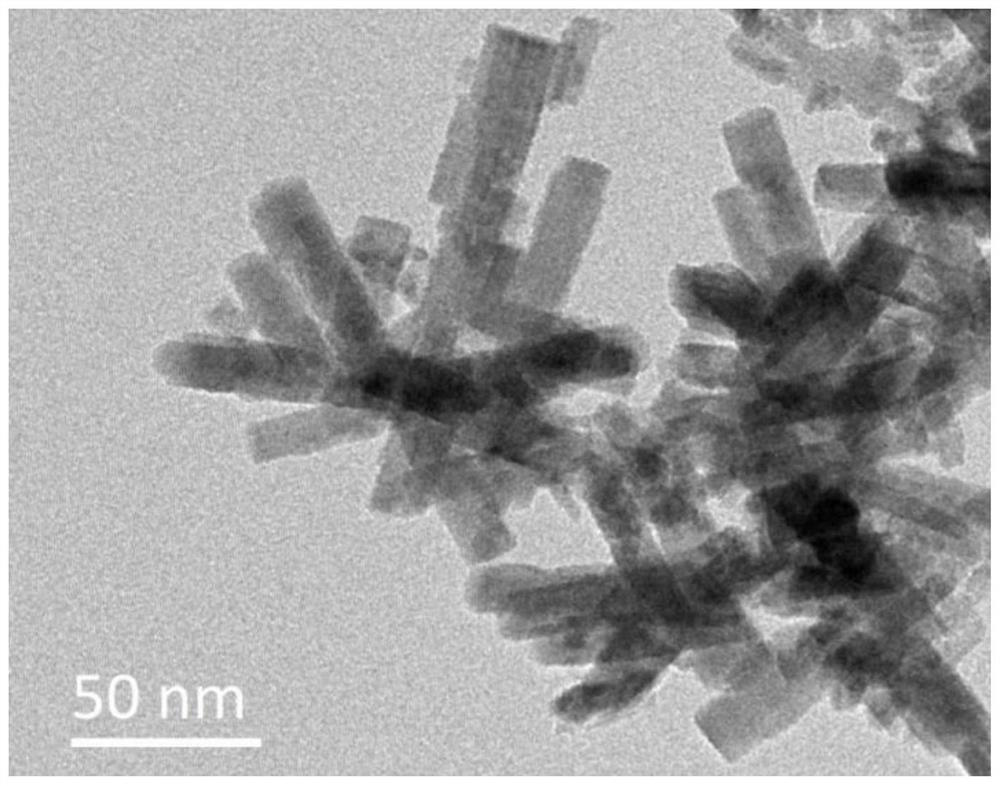

[0085] Add 0.2 parts of tungsten chloride to 40 parts of absolute ethanol and mix evenly to obtain a bright yellow mixed solution; then add 0.05 parts of cesium hydroxide to the aqueous tungsten chloride solution and stir evenly. Next, 10 parts of acetic acid solution was added to obtain a precursor solution, and the precursor solution was placed in a high-temperature reaction kettle at a temperature of 240° C. for 20 hours to obtain a cesium-doped tungsten oxide nanorod solution.

[0086] Put 8 mL of the above-mentioned cesium-doped oxide nanorod solution into a centrifuge test tube, and centrifuge at a speed of 10,000 rpm for 10 minutes; remove the upper layer solution, and use deionized water to disperse the precipitate to obtain cesium-doped tungsten oxide nanorods of 50nm to 70nm .

[0087] Mix 0.05 parts of cesium-doped tungsten oxide nanorods, 8 parts of film-forming agent and 1000 parts of water to form a mixed solution, place the mixed solution in an ultrasonic machin...

Embodiment 2

[0100] Add 0.25 parts of tungsten chloride to 40 parts of absolute ethanol and mix evenly to obtain a bright yellow mixed solution; then add 0.06 parts of cesium hydroxide to the aqueous tungsten chloride solution and stir evenly. Next, 10 parts of acetic acid solution was added to obtain a precursor solution, and the precursor solution was placed in a high-temperature reaction kettle at a temperature of 240° C. for 20 hours to obtain a cesium-doped tungsten oxide nanorod solution.

[0101] Put 8 mL of the above-mentioned cesium-doped oxide nanorod solution into a centrifuge test tube, and centrifuge at a speed of 10,000 rpm for 10 minutes; remove the upper layer solution, and use deionized water to disperse the precipitate to obtain cesium-doped tungsten oxide nanorods of 50nm to 70nm .

[0102] Mix 0.1 part of cesium-doped tungsten oxide nanorods, 7 parts of film-forming agent and 1000 parts of water to form a mixed solution, place the mixed solution in an ultrasonic machine...

Embodiment 3

[0115] Add 0.29 parts of tungsten chloride to 40 parts of absolute ethanol and mix evenly to obtain a bright yellow mixed solution; then add 0.065 parts of cesium hydroxide to the aqueous tungsten chloride solution and stir evenly. Next, 10 parts of acetic acid solution was added to obtain a precursor solution, and the precursor solution was placed in a high-temperature reaction kettle at a temperature of 240° C. for 20 hours to obtain a cesium-doped tungsten oxide nanorod solution.

[0116] Put 8 mL of the above-mentioned cesium-doped oxide nanorod solution into a centrifuge test tube, and centrifuge at a speed of 10,000 rpm for 10 minutes; remove the upper layer solution, and use deionized water to disperse the precipitate to obtain cesium-doped tungsten oxide nanorods of 50nm to 70nm .

[0117] Mix 0.2 parts of cesium-doped tungsten oxide nanorods, 8 parts of film-forming agent and 1000 parts of water to form a mixed solution, place the mixed solution in an ultrasonic machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com