Nanometer MnO2/PTFE composite material and preparation method and application thereof

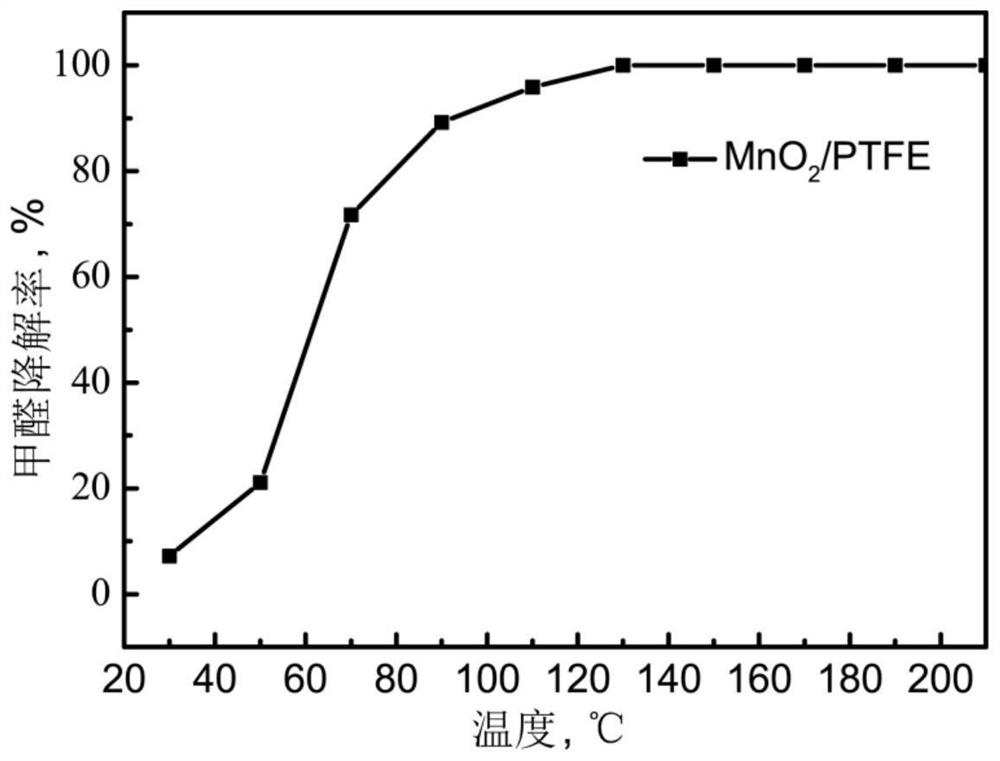

A composite material, PTFE technology, applied in the preparation field of nano-MnO2/PTFE composite material, can solve the problems of restricting large-scale commercial production, unsatisfactory circulation effect, complicated recycling and the like, and achieves improved thermal catalytic activity, low price, Good regeneration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

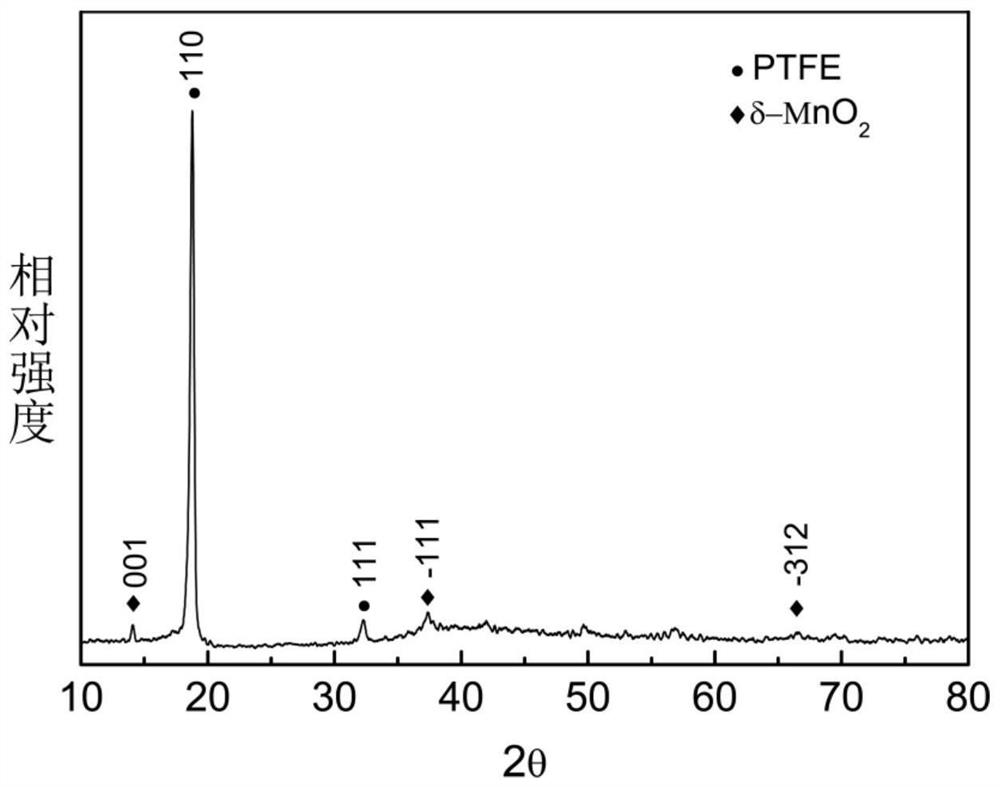

[0042] (1) Accurately weigh 3.79g (0.024mol) potassium permanganate and dissolve it in 60mL of deionized water, stir until potassium permanganate is completely dissolved in deionized water to obtain potassium permanganate solution;

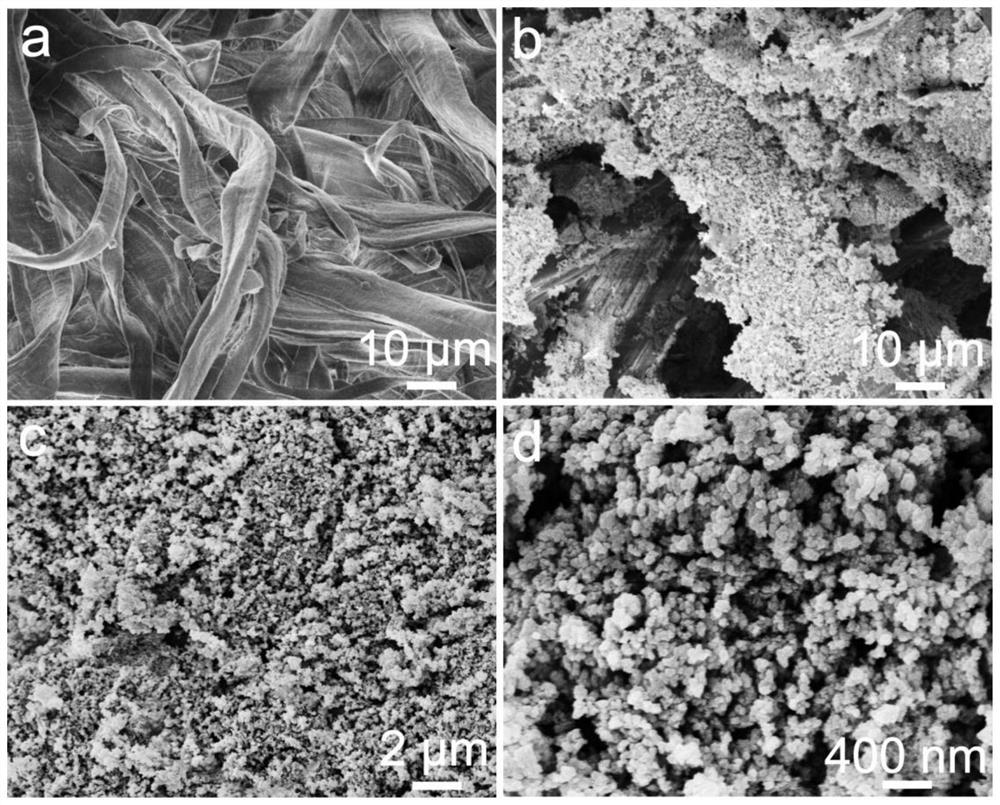

[0043] Take a piece of PTFE (weighing 1.26g) and wash it with acetone and water for 2-5 times successively, dry it, then transfer it to the ethanol solution for 10-30s, and dry it; add PTFE to the potassium permanganate solution, and the PTFE and Potassium permanganate solution has a solid-to-liquid ratio of 0.021g / mL, let it stand at room temperature for 2 hours, take it out and drain it for 10 minutes.

[0044] (2) Accurately weigh 5.07g (0.030mol) of manganese sulfate and dissolve it in 60mL of deionized water, stir until manganese sulfate is completely dissolved in deionized water to obtain a manganese sulfate solution, put the above-mentioned PTFE material into the manganese sulfate solution, and Aging at room temperature for 12h.

[0045] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com