Preparation method of biomass charcoal-based supercapacitor electrode material

A technology for supercapacitors and electrode materials, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, chemical instruments and methods, etc., to achieve the effects of controllable pore structure, simple preparation process, and narrow pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

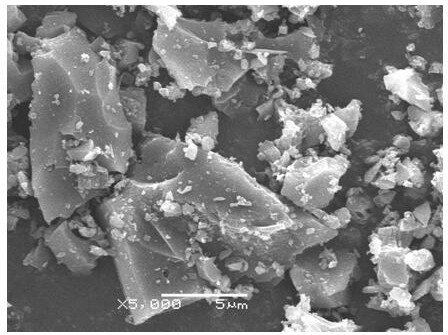

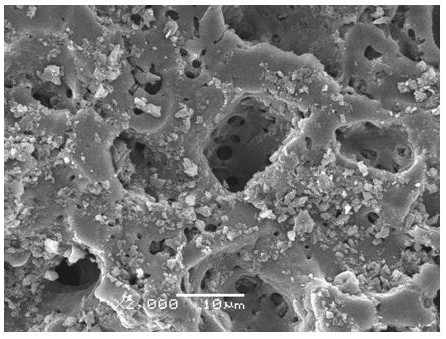

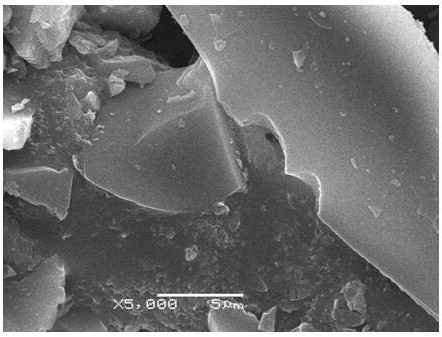

Image

Examples

Embodiment 1

[0036] The walnut shells were dried and crushed, washed several times with deionized water and 1 mol / L hydrochloric acid, and dried. A proper amount of walnut shells were put into a quartz boat, placed in a tube furnace, and carbonized in a nitrogen atmosphere. The heating rate was raised to 300 °C at a rate of 3 °C / min, and the carbonization time was 90 min to obtain carbonized walnut shells.

[0037] KOH and carbonized walnut shells were mixed according to the alkali-carbon mass ratio of 2:1, a small amount of water was added dropwise during the grinding process, and the mixture was uniformly placed in a drying oven at 70 °C for drying. The mixture was put into a quartz boat and activated in a tube furnace under the protection of nitrogen. The heating rate was raised to 600 °C at a rate of 3 °C / min, activated for 1 h, and then cooled to room temperature at a rate of 2 °C / min. mol / L hydrochloric acid solution, suction filtration, and distilled water suction filtration washing...

Embodiment 2

[0041] The melon seed shells were washed several times with deionized water and 1 mol / L hydrochloric acid, and dried. Put an appropriate amount of melon seed shells in a quartz boat, place them in a tube furnace, and carbonize them in a nitrogen atmosphere. The heating rate is raised to 350 °C at a rate of 5 °C / min, and the carbonization time is 100 min to obtain carbides.

[0042] Mix KOH and carbonized melon seed shells according to the mass ratio of alkali to carbon of 3:1, add a small amount of water dropwise during the grinding process, mix well and place them in a drying oven at 80 °C for drying. Put the mixture into a quartz boat and activate it in a tube furnace under the protection of nitrogen. The heating rate was raised to 600 °C at a rate of 3 °C / min, activated for 90 min, and then cooled to room temperature at a rate of 5 °C / min. mol / L hydrochloric acid solution, suction filtration, and distilled water suction filtration washing, after washing to neutrality, dryin...

Embodiment 3

[0046] Rhizobia were washed several times with deionized water and 1 mol / L hydrochloric acid, and dried. Put an appropriate amount of rhizobia into a quartz boat, place them in a tube furnace, and carbonize them under a nitrogen atmosphere. The heating rate was raised to 350 °C at a rate of 1 °C / min, and the carbonization time was 120 min to obtain carbonized rhizobia.

[0047] Mix KOH and carbonizing rhizobia according to the mass ratio of alkali to carbon at 2:1, add a small amount of water dropwise during the grinding process, mix well, and then place them in a drying oven at 70 °C for drying. Put the mixture into a quartz boat and activate it in a tube furnace under the protection of nitrogen. The heating rate was raised to 700 °C at a rate of 3 °C / min, activated for 60 min, and then cooled to room temperature at a rate of 6 °C / min. mol / L hydrochloric acid solution, suction filtration, and distilled water suction filtration washing, after washing to neutrality, drying to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com