A preparation method of non-fired glaze, non-fired glaze and inorganic substrate

A technology of fly ash and mixture, applied in the field of inorganic non-metallic materials, can solve the problems of poor performance of surface coating, cumbersome coating process, poor corrosion resistance, etc., to improve the overall gloss, improve calcium absorption capacity and Filling effect, optimizing the effect of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of non-fired glaze, comprising the following steps:

[0026] (1) Mix and stir fly ash, silane coupling agent and water evenly, dry and grind to obtain modified fly ash;

[0027] (2) Mix Portland cement, quartz powder, quartz sand and corundum sand evenly to obtain mixture A;

[0028] (3) Mix and stir the nano-alumina sol and water evenly to obtain a mixture B;

[0029] (4) The modified fly ash, mixture A and mixture B are mixed and ball milled to prepare an unfired glaze.

[0030] In the present invention, the fly ash is modified by using the silane coupling agent. In the glass body of the modified fly ash modified by the silane coupling agent, spherical glass microspheres are the main ones, and spherical glass beads are mainly spherical. The particles can play a lubricating role in the slurry, better fill the gaps between the raw materials in the slurry, increase the bulk density of the raw materials in the slurry, and modify the fly ash by using...

Embodiment 1

[0064] A preparation method of non-fired glaze, comprising the following steps:

[0065] (1) According to the calculation of parts by weight, mix and stir 25 parts of fly ash, 3 parts of silane coupling agent (specifically silane coupling agent KH-570) and 5 parts of water, dry and grind to obtain modified fly ash ;

[0066] (2) Calculated in parts by weight, 25 parts of Portland cement, 5 parts of quartz powder (300 mesh), 25 parts of quartz sand (40-100 mesh), 13 parts of corundum sand (mesh 80 mesh), 2 parts of water reducer (specifically polycarboxylate high performance water reducer PCE8020) and 3 parts of dispersant (specifically glyceryl stearate) were uniformly mixed to obtain mixture A;

[0067] (3) 0.5 parts of nano-alumina sol (the mass concentration of the nano-alumina sol is 15%) and 15 parts of water were mixed and stirred evenly to obtain a mixture B;

[0068] (4) The modified fly ash, mixture A and mixture B were mixed and ball-milled for 10 minutes to prepar...

Embodiment 2

[0070] A preparation method of non-fired glaze, comprising the following steps:

[0071] (1) Calculated in parts by weight, mix and stir 15 parts of fly ash, 1 part of silane coupling agent (specifically silane coupling agent KH-570) and 4 parts of water, dry and grind to obtain modified fly ash ;

[0072] (2) Calculated in parts by weight, 15 parts of Portland cement, 1 part of quartz powder (300 mesh), 15 parts of quartz sand (40-100 mesh), 10 parts of corundum sand (mesh 80 mesh), 1 part of water reducer (specifically polycarboxylate high-performance water reducer PCE8020) and 1 part of dispersant (specifically glyceryl stearate) were mixed uniformly to obtain mixture A;

[0073] (3) 0.3 parts of nano-alumina sol (the mass concentration of the nano-alumina sol is 15%) and 9 parts of water were mixed and stirred evenly to obtain a mixture B;

[0074] (4) The modified fly ash, mixture A and mixture B were mixed and ball-milled for 10 minutes to prepare an unfired glaze.

PUM

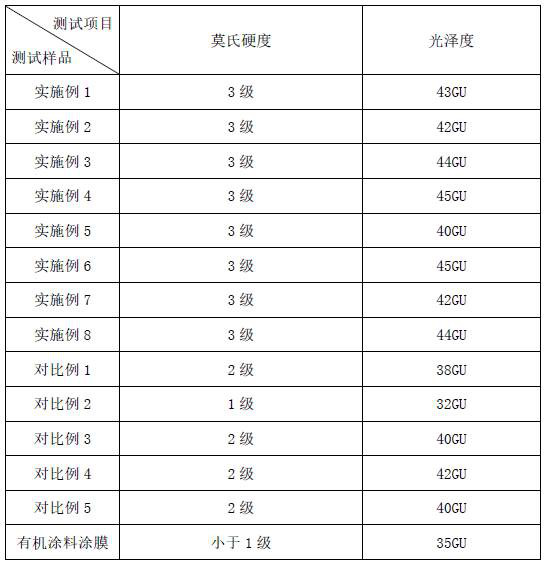

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com