A kind of bio-based flame retardant microcapsule and preparation method thereof

A flame retardant, bio-based technology, applied in the field of flame retardant materials, to achieve the effect of green source of raw materials, high packaging efficiency, excellent thermal stability and flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

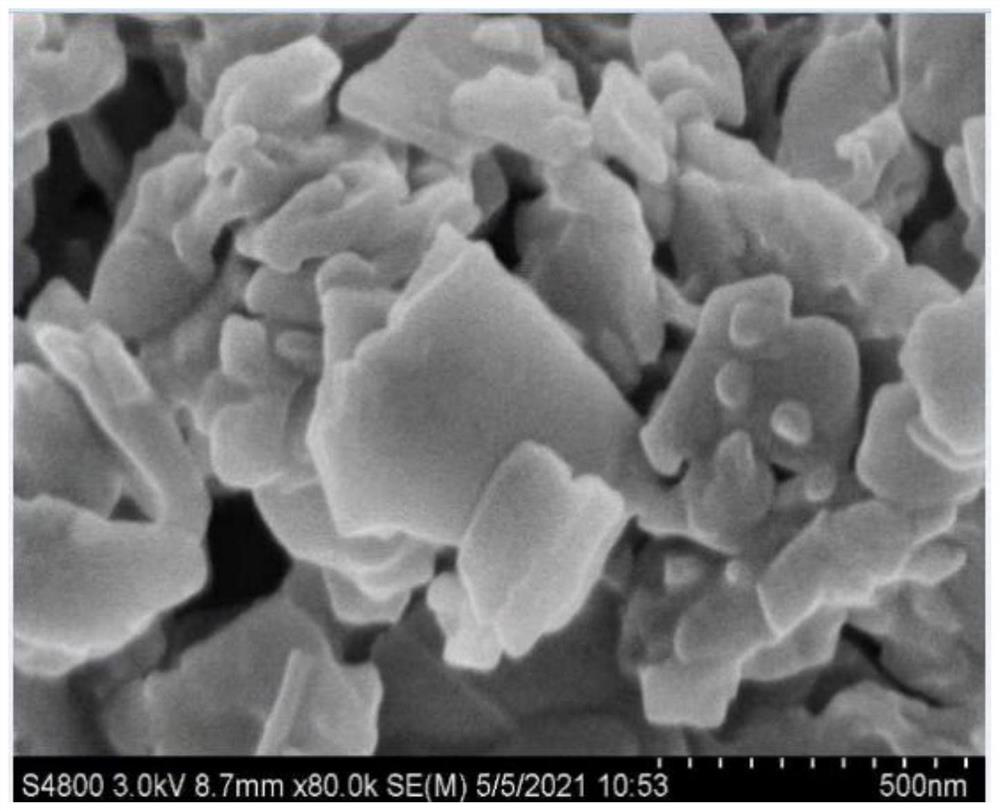

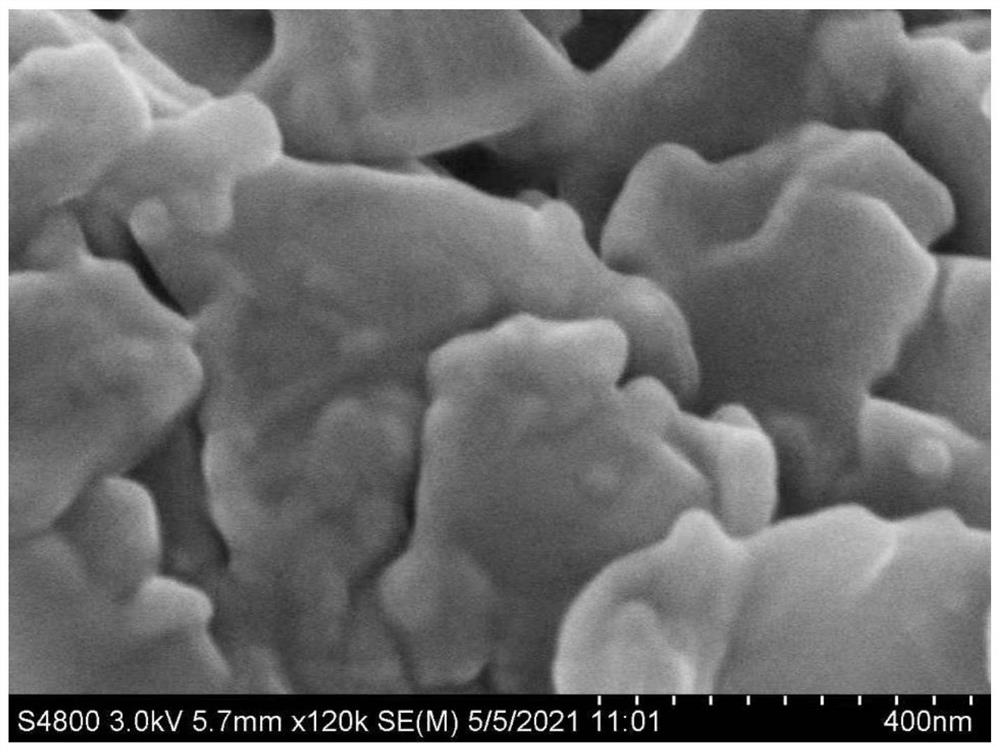

Image

Examples

Embodiment 1

[0045] The embodiment of the present invention provides a preparation method of bio-based flame retardant microcapsules, which specifically includes the following steps:

[0046] Step a, add 1.0g dimethylolpropionic acid (DMPA), 7.54g phytic acid (PA) and 7.06g melamine (MA) into 60mL deionized water respectively, disperse evenly, then stir at 110r / min, 85 Under the condition of ℃, add the 2,2-dimethylol propionic acid dispersion liquid dropwise to the melamine dispersion liquid, react for 2 hours, then slowly add the phytic acid dispersion liquid dropwise into the reaction system, and continue the reaction after all the dropwise addition is completed 3h, suction filtration, washing, drying, core material;

[0047] Step b, weigh 13.5g of polypropylene glycol (PPG1000) into a reactor with PTFE stirring paddle, vacuum dehydrate at 120°C for 1h, then cool down to 85°C, blow nitrogen, install a condensing reflux tube, and add 3.3g of toluene diisocyanate (TDI) and 1.2g dimethylol...

Embodiment 2

[0051] The embodiment of the present invention provides a preparation method of bio-based flame retardant microcapsules, which specifically includes the following steps:

[0052] Step a, add 2.6g dimethylolpropionic acid (DMPA), 7.54g phytic acid (PA) and 7.06g melamine (MA) into 60mL deionized water respectively, disperse evenly, then at a stirring speed of 100r / min, 80 Under the condition of ℃, add the 2,2-dimethylolpropionic acid dispersion liquid dropwise to the melamine dispersion liquid, react for 3 hours, then slowly add the phytic acid dispersion liquid dropwise into the reaction system, after all the dropwise addition is completed, continue the reaction 4h, suction filtration, washing, drying, core material;

[0053] Step b, weigh 13.5g of polypropylene glycol (PPG1000) into the reactor with PTFE stirring paddle, vacuum dehydrate at 120°C for 1h, then cool down to 75°C, blow nitrogen, install a condensing reflux tube, and add 3.3g of toluene diisocyanate (TDI) and 1....

Embodiment 3

[0057] The embodiment of the present invention provides a preparation method of bio-based flame retardant microcapsules, which specifically includes the following steps:

[0058] Step a, add 0.55g dimethylolpropionic acid (DMPA), 7.95g phytic acid (PA) and 3.1g melamine (MA) into 60mL deionized water respectively, disperse evenly, then stir at 100r / min, 75 Under the condition of ℃, add the 2,2-dimethylol propionic acid dispersion liquid dropwise to the melamine dispersion liquid, react for 4 hours, then slowly add the phytic acid dispersion liquid dropwise into the reaction system, and continue the reaction after all the dropwise addition is completed 5h, suction filtration, washing, drying, core material;

[0059] Step b, weigh 11.4g of polypropylene glycol (PPG1000) and add it to a reactor with a PTFE stirring paddle, vacuum dehydrate at 120°C for 1 hour, then cool down to 80°C, blow nitrogen, install a condensing reflux tube, and add 5.41g of toluene diisocyanate (TDI) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com