Rare earth borate crystal material, and preparation method and application thereof

A crystal material, borate technology, applied in the direction of polycrystalline material growth, crystal growth, luminescent materials, etc., can solve the problems of low quantum yield, limited application, etc., to achieve good thermal stability, low price, not easy to deliquescence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Growth of Gadolinium-Containing Borate Compound Rb by Flux Method 2 LiGdB 2 o 6 crystals.

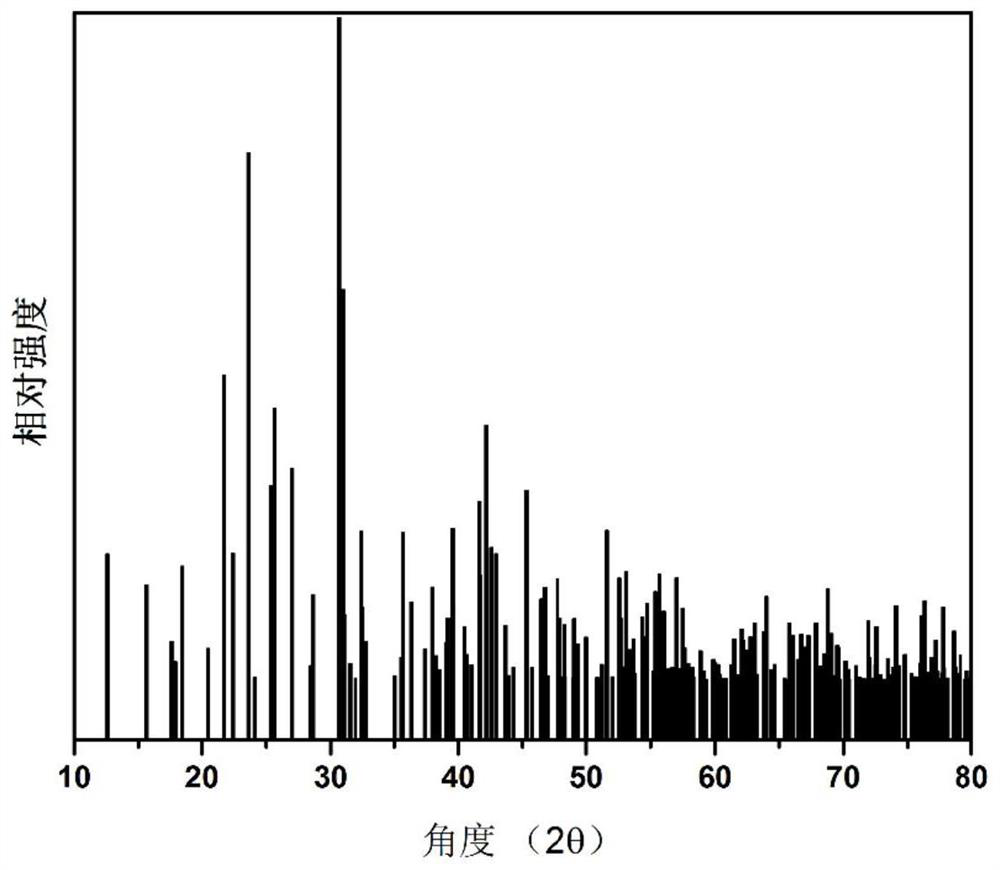

[0053] 0.0006molRb 2 CO 3 , 0.0003molLi 2 CO 3 , 0.0001molGd 2 o 3 , 0.001molH 3 BO 3 Mix and grind evenly, transfer to a platinum crucible, place the platinum crucible containing the mixed raw materials in a muffle furnace, raise the temperature to 800°C at a rate of 60°C / h, and keep at this temperature for 24h to make the melt fully homogeneous. Then the melt was slowly cooled to 500°C at a cooling rate of 5°C / h, the power was turned off, and the melt was naturally cooled to room temperature to obtain transparent millimeter-sized Rb 2 LiGdB 2 o 6 (referred to as RLGBO) small crystals, the XRD spectrum is as follows figure 1 shown.

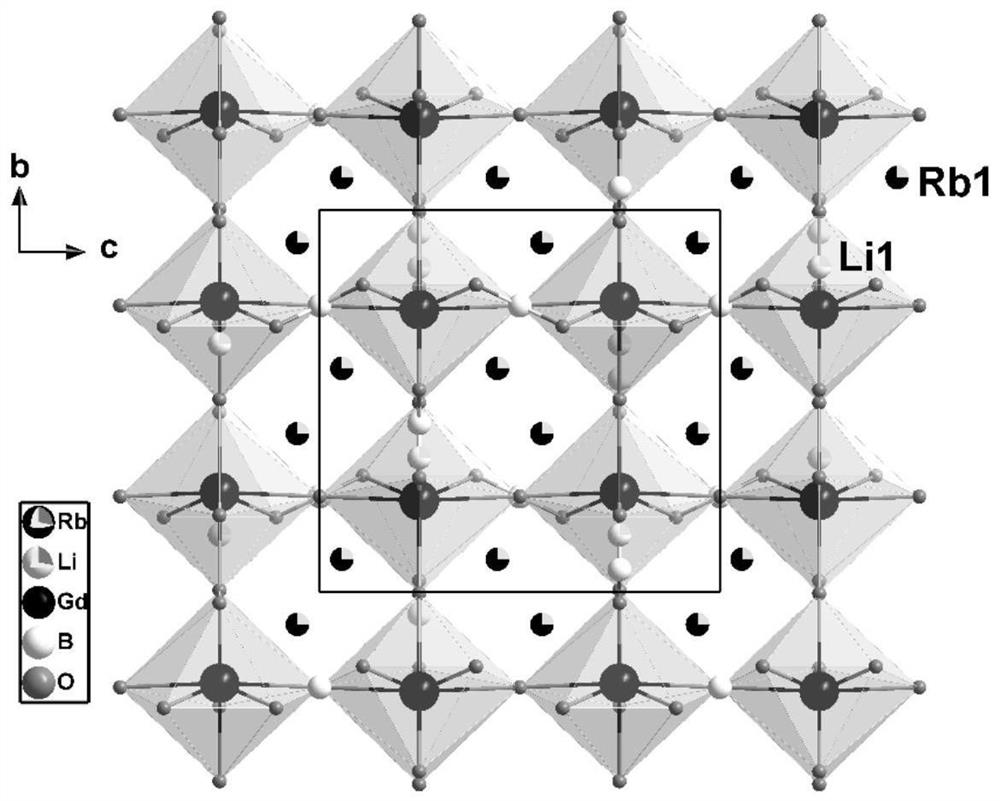

[0054] Using X-ray single crystal diffractometer to determine the structure of the obtained crystal, the crystal structure is shown in figure 2 shown. Crystalclear software was used for refinement of unit cell parameters and data re...

Embodiment 2

[0066] Growth of Borate Compound Rb Containing Gadolinium by Flux Method 2 LiGdB 2 o 6 crystals.

[0067] 0.0004mol Rb 2 CO 3 , 0.0001mol Li 2 CO 3 , 0.0001mol Gd 2 o 3 , 0.0004mol H 3 BO 3 Mix and grind evenly, transfer to a platinum crucible, place the platinum crucible containing the mixed raw materials in a muffle furnace, raise the temperature to 800°C at a rate of 60°C / h, and keep at this temperature for 24h to make the melt fully homogeneous. Then the melt was slowly cooled to 500°C at a cooling rate of 5°C / h, the power was turned off, and the melt was naturally cooled to room temperature to obtain transparent millimeter-sized Rb 2 LiGdB 2 o 6(RLGBO for short) small crystals.

Embodiment 3

[0069] Growth of Gadolinium-Containing Borate Compound Rb by Flux Method 2 LiGdB 2 o 6 crystals.

[0070] 0.0005mol Rb 2 CO 3 , 0.0004mol Li 2 CO 3 , 0.0001mol Gd 2 o 3 , 0.0012mol H 3 BO 3 Mix and grind evenly, transfer to a platinum crucible, place the platinum crucible containing the mixed raw materials in a muffle furnace, raise the temperature to 800°C at a rate of 60°C / h, and keep at this temperature for 24h to make the melt fully homogeneous. Then the melt was slowly cooled to 500°C at a cooling rate of 5°C / h, the power was turned off, and the melt was naturally cooled to room temperature to obtain transparent millimeter-sized Rb 2 LiGdB 2 o 6 (RLGBO for short) small crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com