Heteroatom-doped graphene nanofiber non-woven fabric and preparation method thereof

A technology of graphene fiber and nanofiber, which is applied in the direction of fiber raw material processing, fiber chemical characteristics, synthetic cellulose/non-cellulose material pulp/paper, etc., can solve problems that have not been reported before, and achieve the goal of maintaining mechanical stability and Flexibility, increased specific surface area, wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

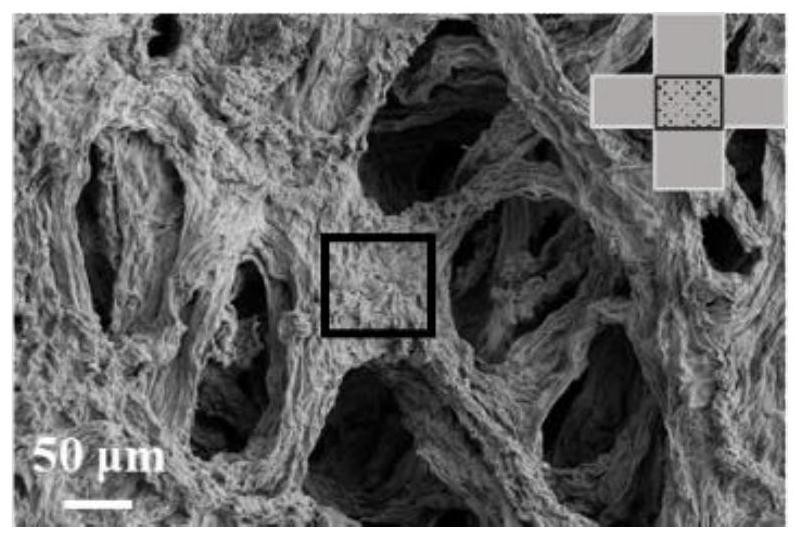

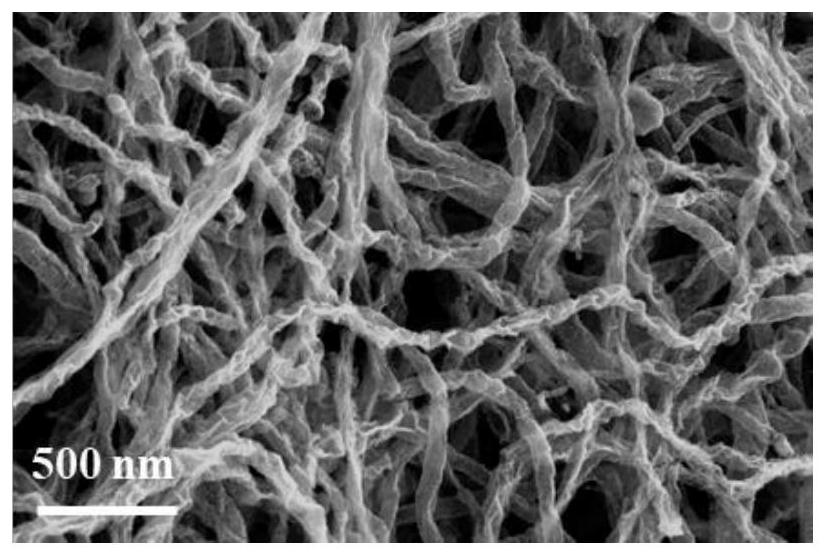

[0021] A heteroatom-doped graphene nanofiber non-woven fabric, its preparation method may further comprise the steps:

[0022] (1) The graphene oxide / water solution with a concentration of 10 mg / mL is used as the spinning solution, wherein 10% polyaniline is added in a mass fraction, and saturated potassium chloride methanol solution is used as a coagulation bath for continuous wet spinning. Dry the obtained composite fiber in an oven at a temperature not higher than 70°C for 12 hours.

[0023] (2) Disperse the dried composite fiber in a 3:1 mixture of ethanol and water, and use a mixer to crush it and mix it evenly to obtain a suspension of the composite fiber, which is filtered and deposited through a filter screen, and obtained on the filter screen. Composite fiber non-woven fabric, the composite fiber non-woven fabric was washed three times with ethanol, and dried at 80°C.

[0024] (3) the dried composite fiber non-woven fabric in saturated FeCl 3 Soak in medium for 6h, ...

Embodiment 2

[0027] A heteroatom-doped graphene nanofiber non-woven fabric, its preparation method may further comprise the steps:

[0028] (1) Graphene oxide / N with a concentration of 10 mg / mL, N-dimethylformamide solution is the spinning solution, wherein adding hexachlorocyclotriphosphazene with a mass fraction of 10%, and ethyl acetate as the coagulation bath , for continuous wet spinning. Dry the obtained composite fiber in an oven at a temperature not higher than 70°C for 12 hours.

[0029] (2) Disperse the dried composite fiber in a 3:1 mixture of ethanol and water, and use a mixer to crush it and mix it evenly to obtain a suspension of the composite fiber, which is filtered and deposited through a filter screen, and obtained on the filter screen. Composite fiber non-woven fabric, the composite fiber non-woven fabric was washed three times with ethanol, and dried at 80°C.

[0030] (3) the dried composite fiber non-woven fabric in saturated FeCl 3 Soak in medium for 6h, dry to obt...

Embodiment 3

[0034] A heteroatom-doped graphene nanofiber non-woven fabric, its preparation method may further comprise the steps:

[0035] (1) The graphene oxide / water solution with a concentration of 10 mg / mL is used as the spinning solution, wherein 5% methionine is added in a mass fraction, and saturated potassium chloride methanol solution is used as a coagulation bath for continuous wet spinning . Dry the obtained composite fiber in an oven at a temperature not higher than 70°C for 12 hours.

[0036] (2) Disperse the dried composite fiber in a 3:1 mixture of ethanol and water, and use a mixer to crush it and mix it evenly to obtain a suspension of the composite fiber, which is filtered and deposited through a filter screen, and obtained on the filter screen. Composite fiber non-woven fabric, the composite fiber non-woven fabric was washed three times with ethanol, and dried at 80°C.

[0037] (3) the dried composite fiber non-woven fabric in saturated FeCl 3 Soak in medium for 6h, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com