Integrated treatment device and method for Hu sheep slaughtering, domestic sewage and cooked food processing wastewater

A technology for domestic sewage and processing wastewater, which is applied in the fields of food industry wastewater treatment, animal processing wastewater treatment, heating water/sewage treatment, etc. It can solve the problems of inability to mature solid substances, difficulty in separation and degradation, waste of manpower and material resources, etc., and shorten the overall The effects of process steps, reduction of harmful substances, and convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] An integrated treatment method for Hu sheep slaughter, domestic sewage and cooked food processing wastewater, comprising:

[0048] (1) Concentrated mixing, adding the sewage, domestic sewage and cooked food processing wastewater from the Huyang slaughtering workshop to the pre-adjustment tank, adding lye to adjust the PH to homogenize the water quality, and continuously stirring during the adding process to accelerate the dissolution of lye ,Improve efficiency;

[0049] (2) Solid-liquid separation, the pre-adjusted mixture is added to the integrated treatment device, and the liquid, solid and water-soluble suspended matter are separated and collected;

[0050] (3) Concentration, drying, and dehydration. The solid sediment and minced meat separated from solid and liquid are sequentially added to the sludge adjustment tank and dehydrator for dehydration and drying, and then transported, and the solids are dried and discharged to collect the liquid;

[0051] (4) Separatio...

Embodiment 2

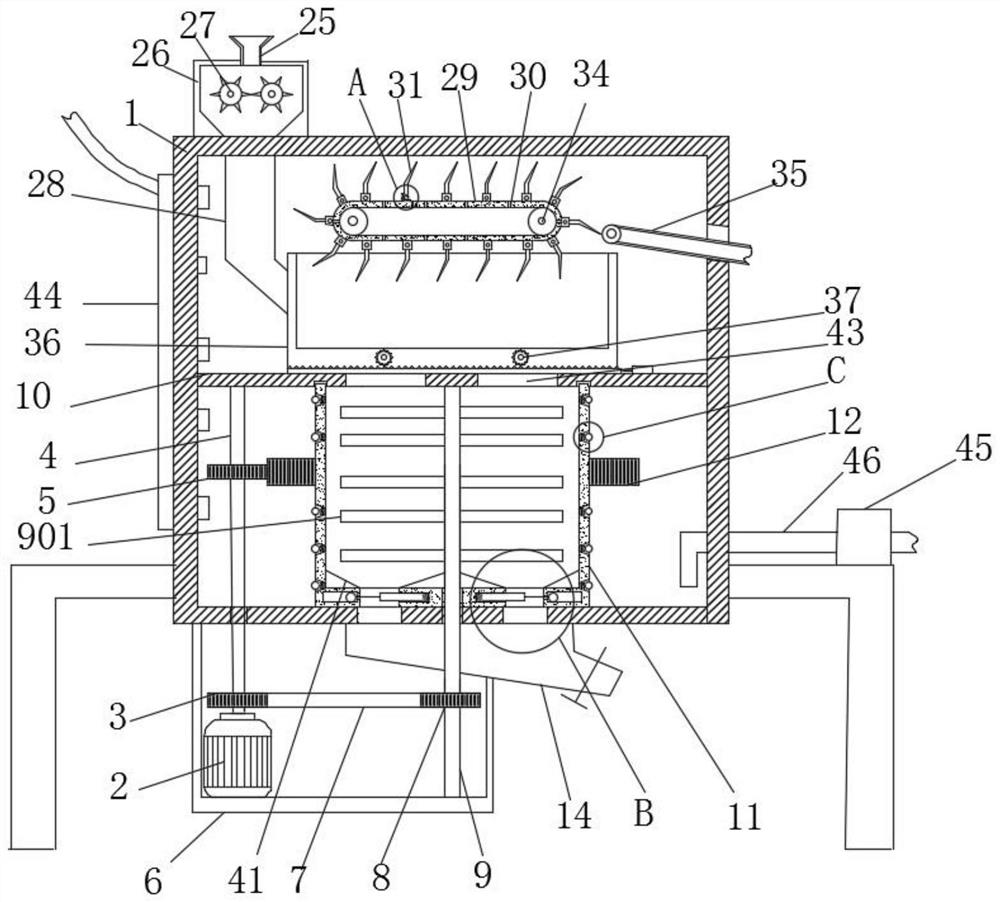

[0057] see Figure 1-4 , 7, on the basis of embodiment 1, the integrated device includes a box body 1, the lower end of the box body 1 is provided with a hopper 14, and the middle part of the box body 1 is fixedly provided with a straight plate 10. The middle part of the straight plate 10 is symmetrically provided with a second drop opening 43;

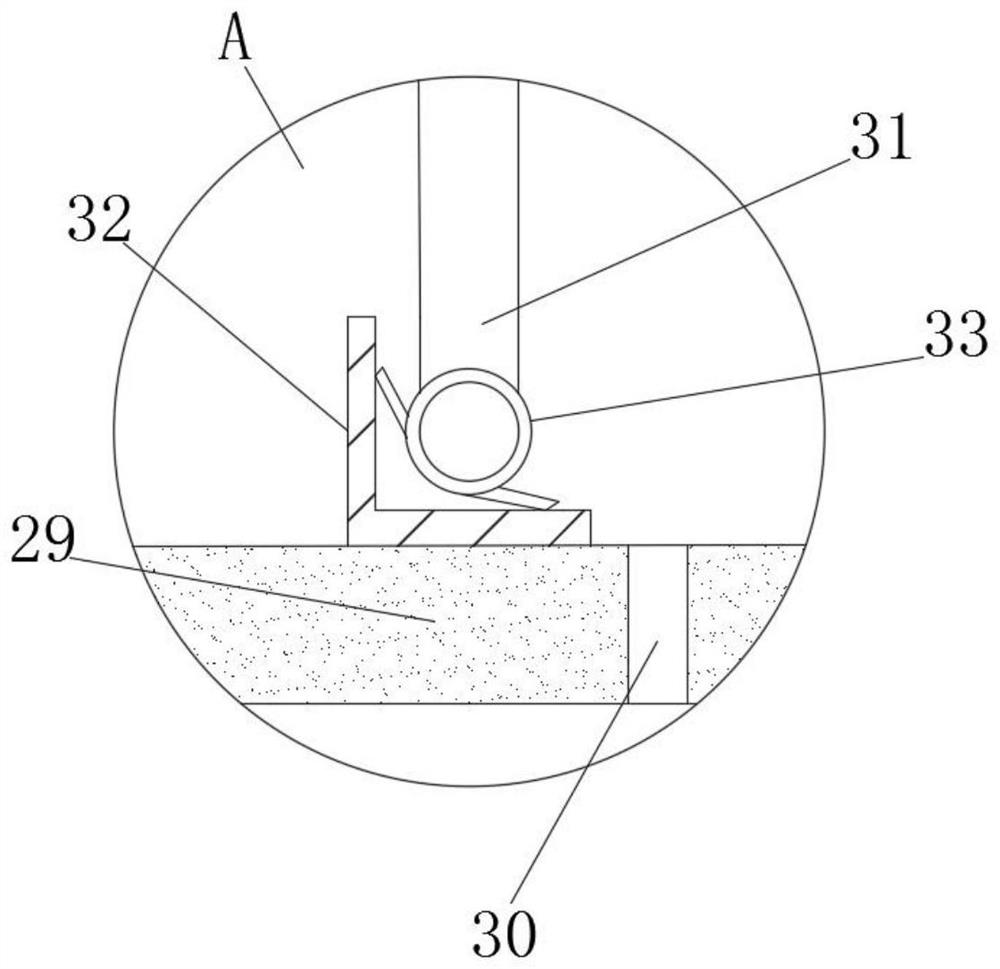

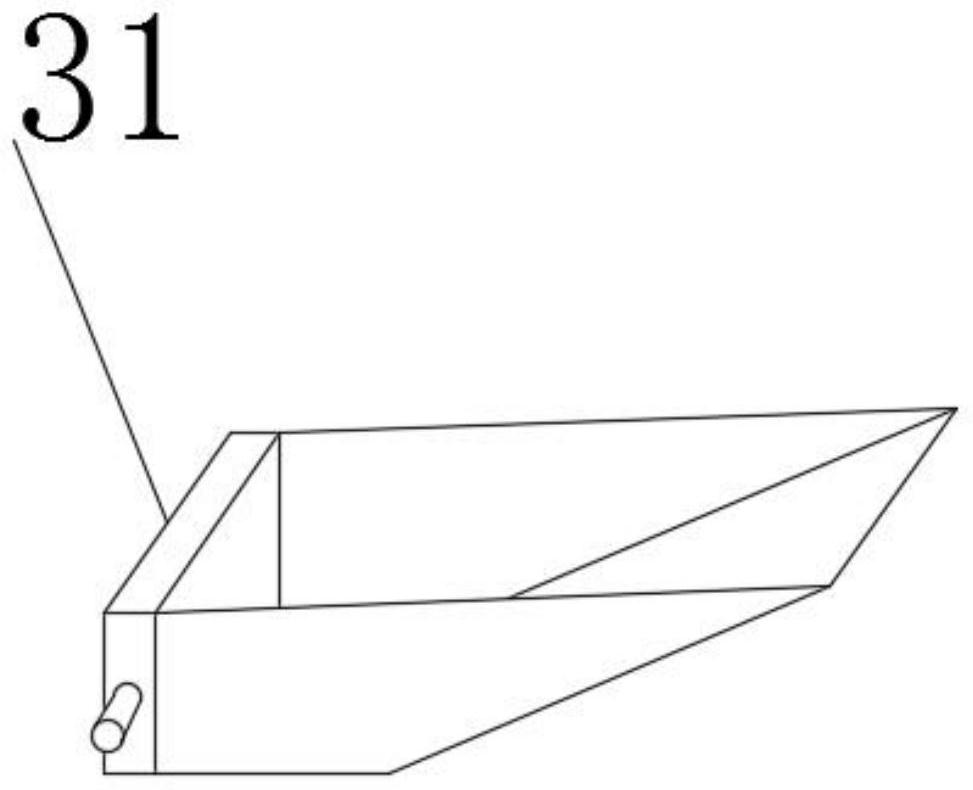

[0058] Suspension removal device, which is arranged on the upper end of the straight plate 10, the suspension removal device includes a settling box 36, above the settling box 36 are provided with two conveying rollers 34 that are rotatably connected to the inner wall of the box body 1, and the conveying rollers 34 pass through Belt 29 transmission connection, the upper end of the transfer belt 29 is equipped with a number of collecting claws 31 through the fixed plate 32, a conveyor belt 35 is installed obliquely on one side of the transfer belt 29, and a first drop opening 42 is symmetrically opened at the lower end of the settling ...

Embodiment 3

[0074] see Figure 5 As shown, on the basis of Embodiment 1, according to the present invention, the switch device includes an arc groove 13 provided at the lower end of the separation cylinder 11, and the symmetrical arc groove wall of the arc groove 13 is provided with a rolling groove 15 and a moving groove 18 respectively. , the rolling groove 15 is provided with a ball 16, the moving groove 18 is slidably provided with an arc plate 19, the arc plate 19 and the ball 16 are fixedly connected by a pull cord 17, and the arc plate 19 is connected to the wall of the moving groove 18 A tension spring 20 is fixedly provided.

[0075] Specifically, the separation cylinder 11 rotates at a high speed, the balls 16 perform centrifugal motion in the rolling groove 15, and the moving plate 19 is pulled by the stay rope 17 to move in the movement groove 18, and the arc groove 13 is blocked. When the separation cylinder 11 stops rotating, The arc groove 13 leaks out and communicates wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap